OPERATION | ||

|

|

|

GAS PURGE PUSHbUTTON

The gas solenoid valve will energize but neither the power source output nor the drive motor will be turned on. The Gas Purge switch is useful for setting the proper flow rate of shielding gas. Flow meters should always be adjusted while the shielding gas is flowing.

FLOW METER

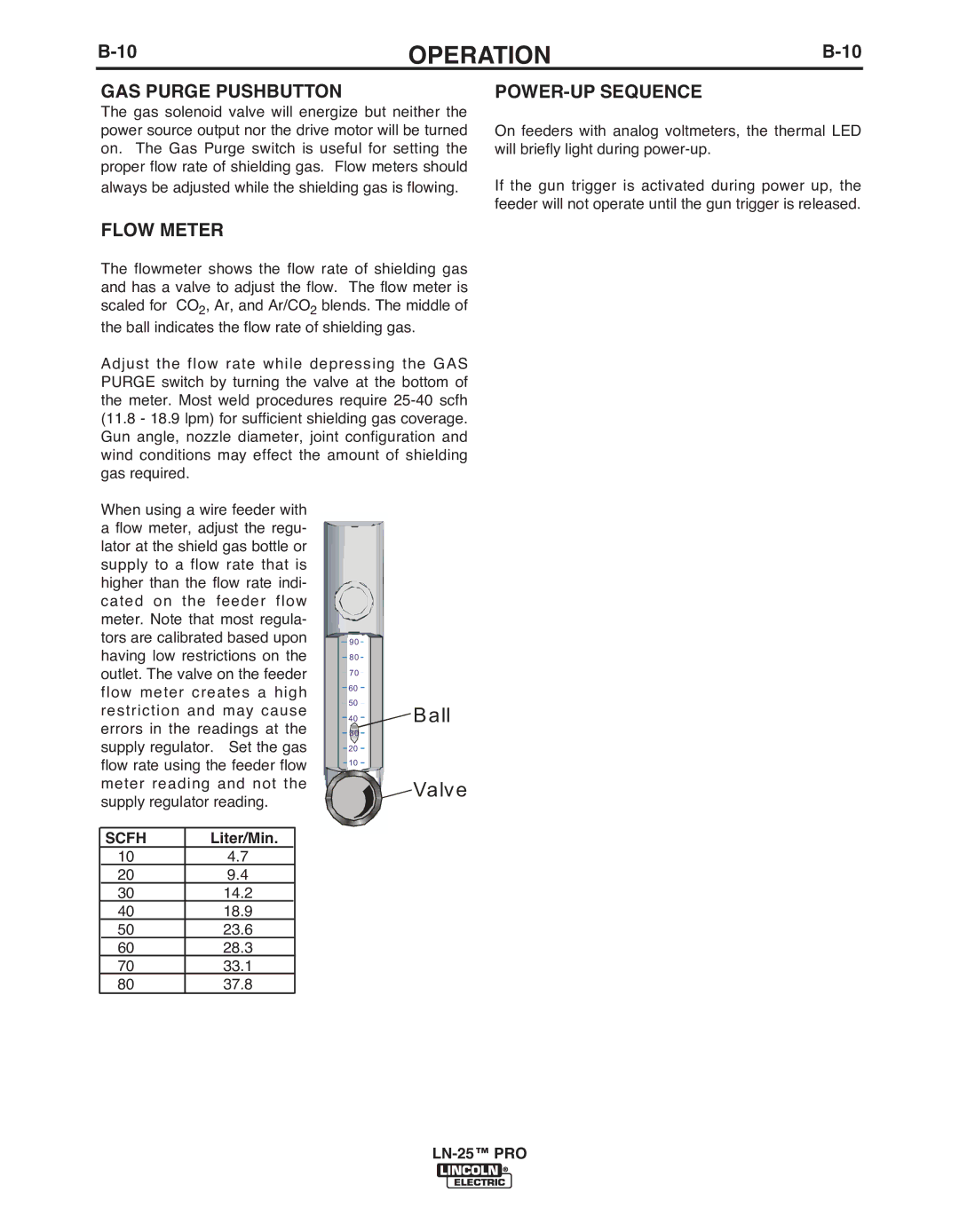

The flowmeter shows the flow rate of shielding gas and has a valve to adjust the flow. The flow meter is scaled for CO2, Ar, and Ar/CO2 blends. The middle of

the ball indicates the flow rate of shielding gas.

Adjust the flow rate while depressing the GAS PURGE switch by turning the valve at the bottom of the meter. Most weld procedures require

POWER-UP SEQUENCE

On feeders with analog voltmeters, the thermal LED will briefly light during

If the gun trigger is activated during power up, the feeder will not operate until the gun trigger is released.

When using a wire feeder with a flow meter, adjust the regu- lator at the shield gas bottle or supply to a flow rate that is higher than the flow rate indi- cated on the feeder flow meter. Note that most regula- tors are calibrated based upon having low restrictions on the outlet. The valve on the feeder flow meter creates a high restriction and may cause errors in the readings at the supply regulator. Set the gas flow rate using the feeder flow meter reading and not the supply regulator reading.

SCFH | Liter/Min. |

10 | 4.7 |

20 | 9.4 |

30 | 14.2 |

40 | 18.9 |

50 | 23.6 |

60 | 28.3 |

70 | 33.1 |

80 | 37.8 |

90 |

|

80 |

|

70 |

|

60 |

|

50 | Ball |

40 | |

30 |

|

20

10

![]()

![]()

![]() Valve

Valve