TROUBLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

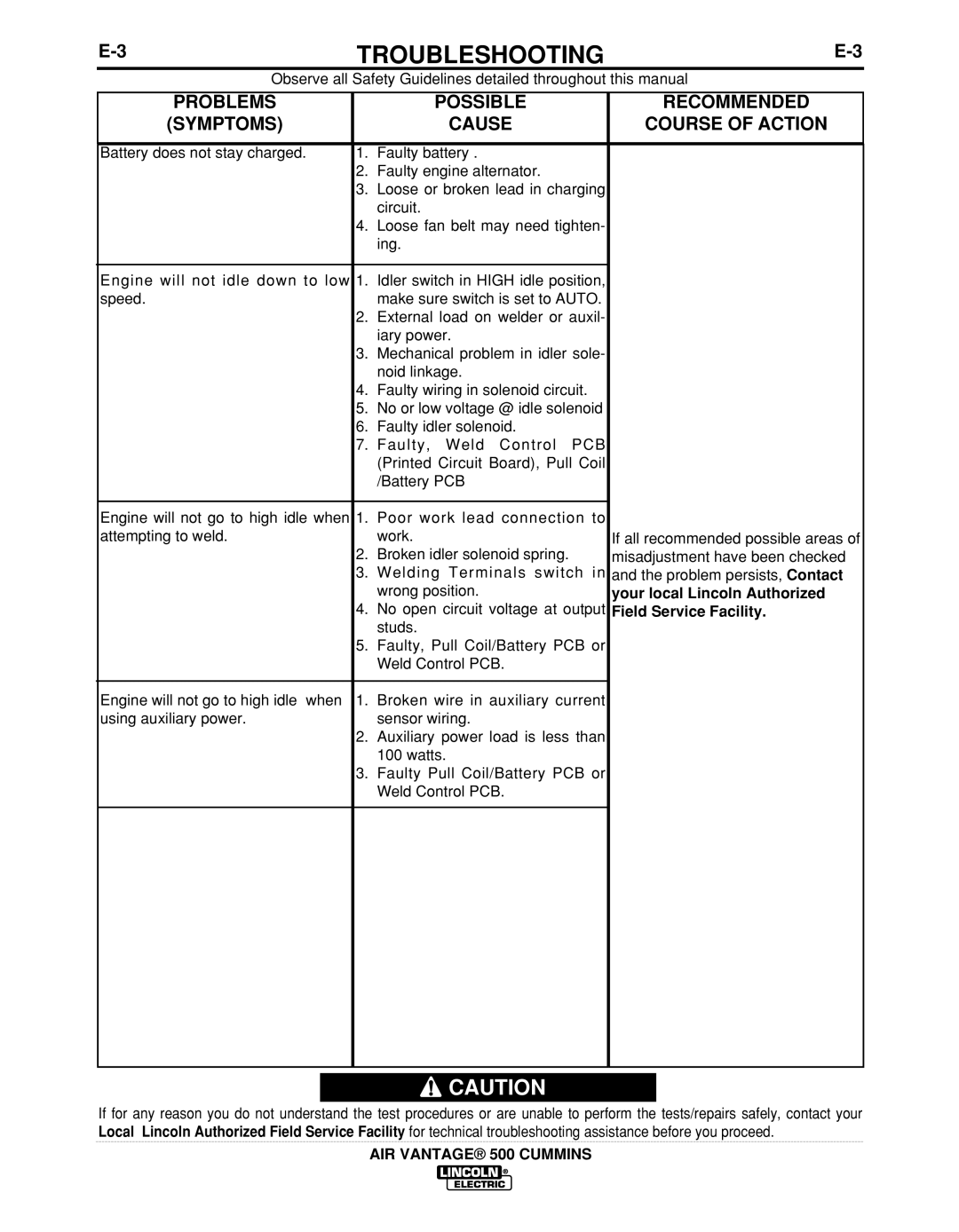

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Battery does not stay charged. | 1. | Faulty battery . | |

| 2. | Faulty engine alternator. | |

| 3. | Loose or broken lead in charging | |

|

| circuit. |

|

| 4. | Loose fan belt may need tighten- | |

|

| ing. |

|

|

|

| |

Engine will not idle down to low | 1. | Idler switch in HIGH idle position, | |

speed. |

| make sure switch is set to AUTO. | |

| 2. | External load on welder or auxil- | |

|

| iary power. | |

| 3. | Mechanical problem in idler sole- | |

|

| noid linkage. | |

| 4. | Faulty wiring in solenoid circuit. | |

| 5. | No or low voltage @ idle solenoid | |

| 6. | Faulty idler solenoid. | |

| 7. | Faulty, | Weld Control PCB |

|

| (Printed Circuit Board), Pull Coil | |

|

| /Battery PCB | |

|

|

| |

Engine will not go to high idle when | 1. | Poor work lead connection to | |

attempting to weld. |

| work. |

|

| 2. | Broken idler solenoid spring. | |

| 3. | Welding | Terminals switch in |

|

| wrong position. | |

| 4. | No open circuit voltage at output | |

|

| studs. |

|

| 5. | Faulty, Pull Coil/Battery PCB or | |

|

| Weld Control PCB. | |

|

|

| |

Engine will not go to high idle when | 1. | Broken wire in auxiliary current | |

using auxiliary power. |

| sensor wiring. | |

| 2. | Auxiliary power load is less than | |

|

| 100 watts. | |

| 3. | Faulty Pull Coil/Battery PCB or | |

|

| Weld Control PCB. | |

|

|

|

|

|

|

|

|

If all recommended possible areas of misadjustment have been checked and the problem persists, Contact your local Lincoln Authorized Field Service Facility.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

AIR VANTAGE® 500 CUMMINS