OPERATION | ||

|

|

|

3.The Mode Push Buttons and Indicators show the current selection made by the corresponding weld push buttons

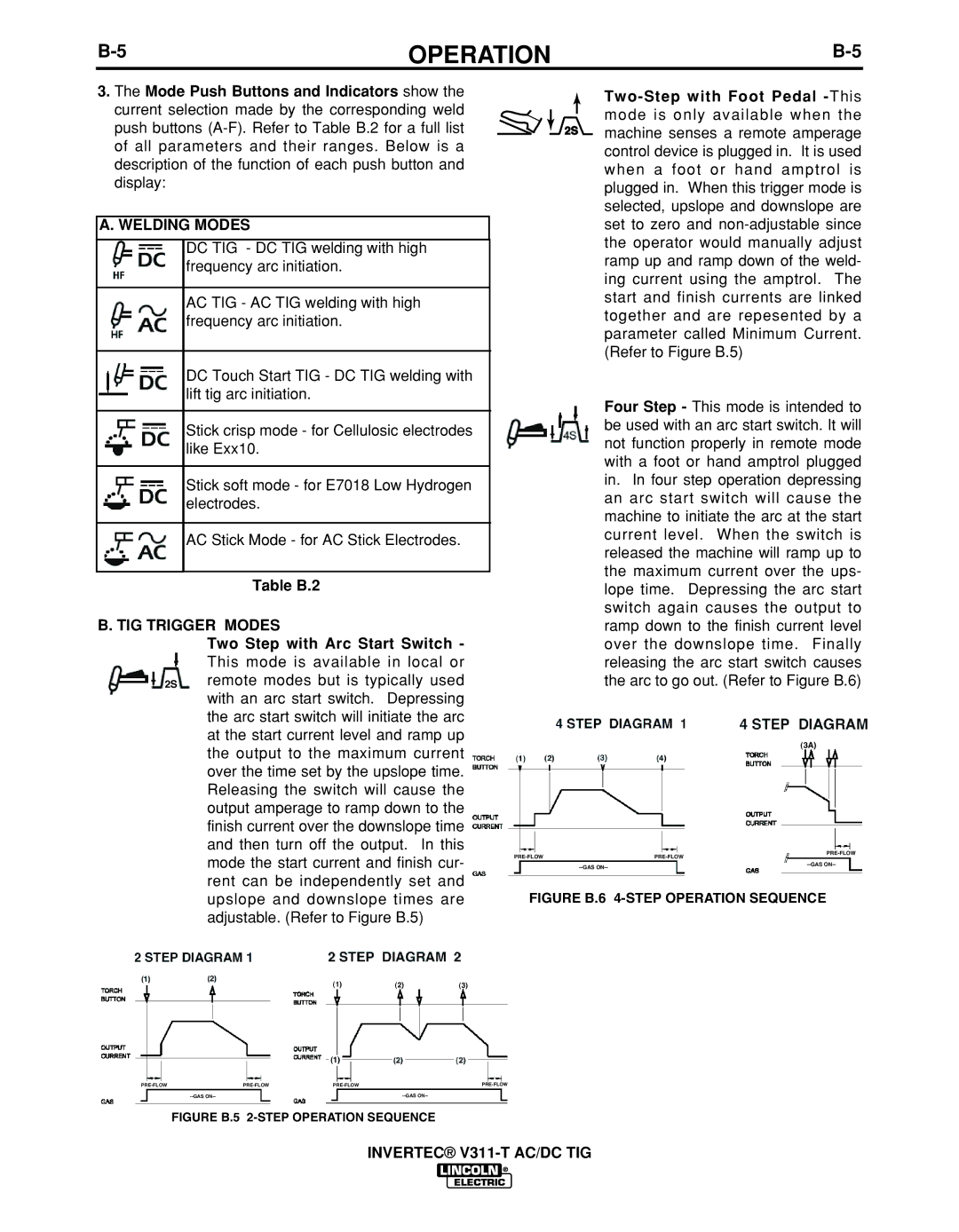

A.WELDING MODES

| DC TIG - DC TIG welding with high |

| frequency arc initiation. |

|

|

| AC TIG - AC TIG welding with high |

| frequency arc initiation. |

|

|

| DC Touch Start TIG - DC TIG welding with |

| lift tig arc initiation. |

|

|

| Stick crisp mode - for Cellulosic electrodes |

| like Exx10. |

|

|

| Stick soft mode - for E7018 Low Hydrogen |

| electrodes. |

|

|

| AC Stick Mode - for AC Stick Electrodes. |

|

|

| Table B.2 |

B. TIG TRIGGER MODES | |

| Two Step with Arc Start Switch - |

| This mode is available in local or |

2S | remote modes but is typically used |

| with an arc start switch. Depressing |

| the arc start switch will initiate the arc |

| at the start current level and ramp up |

| the output to the maximum current |

| over the time set by the upslope time. |

| Releasing the switch will cause the |

| output amperage to ramp down to the |

finish current over the downslope time and then turn off the output. In this mode the start current and finish cur- rent can be independently set and upslope and downslope times are adjustable. (Refer to Figure B.5)

Two-Step with Foot Pedal -This

mode is only available when the 2S machine senses a remote amperage control device is plugged in. It is used when a foot or hand amptrol is plugged in. When this trigger mode is selected, upslope and downslope are set to zero and

(Refer to Figure B.5)

Four Step - This mode is intended to be used with an arc start switch. It will not function properly in remote mode with a foot or hand amptrol plugged in. In four step operation depressing an arc start switch will cause the machine to initiate the arc at the start current level. When the switch is released the machine will ramp up to the maximum current over the ups- lope time. Depressing the arc start switch again causes the output to ramp down to the finish current level over the downslope time. Finally releasing the arc start switch causes the arc to go out. (Refer to Figure B.6)

(3A)

| |||

| |||

|

| ||

|

|

|

FIGURE B.6 4-STEP OPERATION SEQUENCE

(1) | (2) | (3) |

|

|