OPERATING INSTRUCTIONS

2.Arc striking with

a.Except for long stickout Innershield procedures and Tiny Twinarc 1/16 procedures, an

b.Cut electrode to a sharp point.

c.For cold starts, make certain work piece is clean and electrode makes positive contact with plate.

d.For hot starts, travel should be started before wire contacts the work (“on the fly” starting).

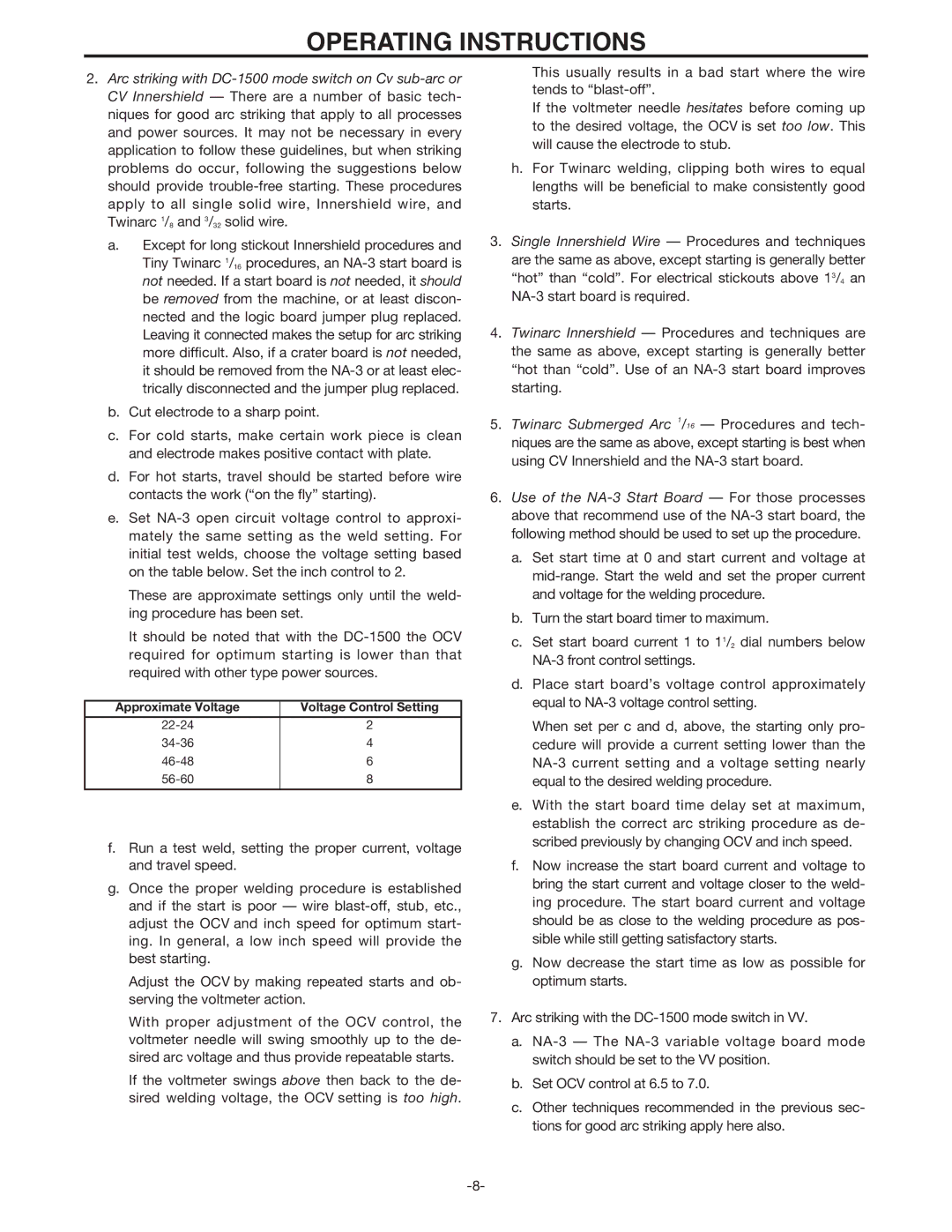

e.Set

These are approximate settings only until the weld- ing procedure has been set.

It should be noted that with the

Approximate Voltage | Voltage Control Setting |

2 | |

4 | |

6 | |

8 | |

|

|

f.Run a test weld, setting the proper current, voltage and travel speed.

g.Once the proper welding procedure is established and if the start is poor — wire

Adjust the OCV by making repeated starts and ob- serving the voltmeter action.

With proper adjustment of the OCV control, the voltmeter needle will swing smoothly up to the de- sired arc voltage and thus provide repeatable starts.

If the voltmeter swings above then back to the de- sired welding voltage, the OCV setting is too high.

This usually results in a bad start where the wire tends to

If the voltmeter needle hesitates before coming up to the desired voltage, the OCV is set too low. This will cause the electrode to stub.

h.For Twinarc welding, clipping both wires to equal lengths will be beneficial to make consistently good starts.

3.Single Innershield Wire — Procedures and techniques are the same as above, except starting is generally better “hot” than “cold”. For electrical stickouts above 13/4 an

4.Twinarc Innershield — Procedures and techniques are the same as above, except starting is generally better “hot than “cold”. Use of an

5.Twinarc Submerged Arc 1/16 — Procedures and tech- niques are the same as above, except starting is best when using CV Innershield and the

6.Use of the

a.Set start time at 0 and start current and voltage at

b.Turn the start board timer to maximum.

c.Set start board current 1 to 11/2 dial numbers below

d.Place start board’s voltage control approximately equal to

When set per c and d, above, the starting only pro- cedure will provide a current setting lower than the

e.With the start board time delay set at maximum, establish the correct arc striking procedure as de- scribed previously by changing OCV and inch speed.

f.Now increase the start board current and voltage to bring the start current and voltage closer to the weld- ing procedure. The start board current and voltage should be as close to the welding procedure as pos- sible while still getting satisfactory starts.

g.Now decrease the start time as low as possible for optimum starts.

7.Arc striking with the

a.

b.Set OCV control at 6.5 to 7.0.

c.Other techniques recommended in the previous sec- tions for good arc striking apply here also.