OPERATING INSTRUCTIONS

General

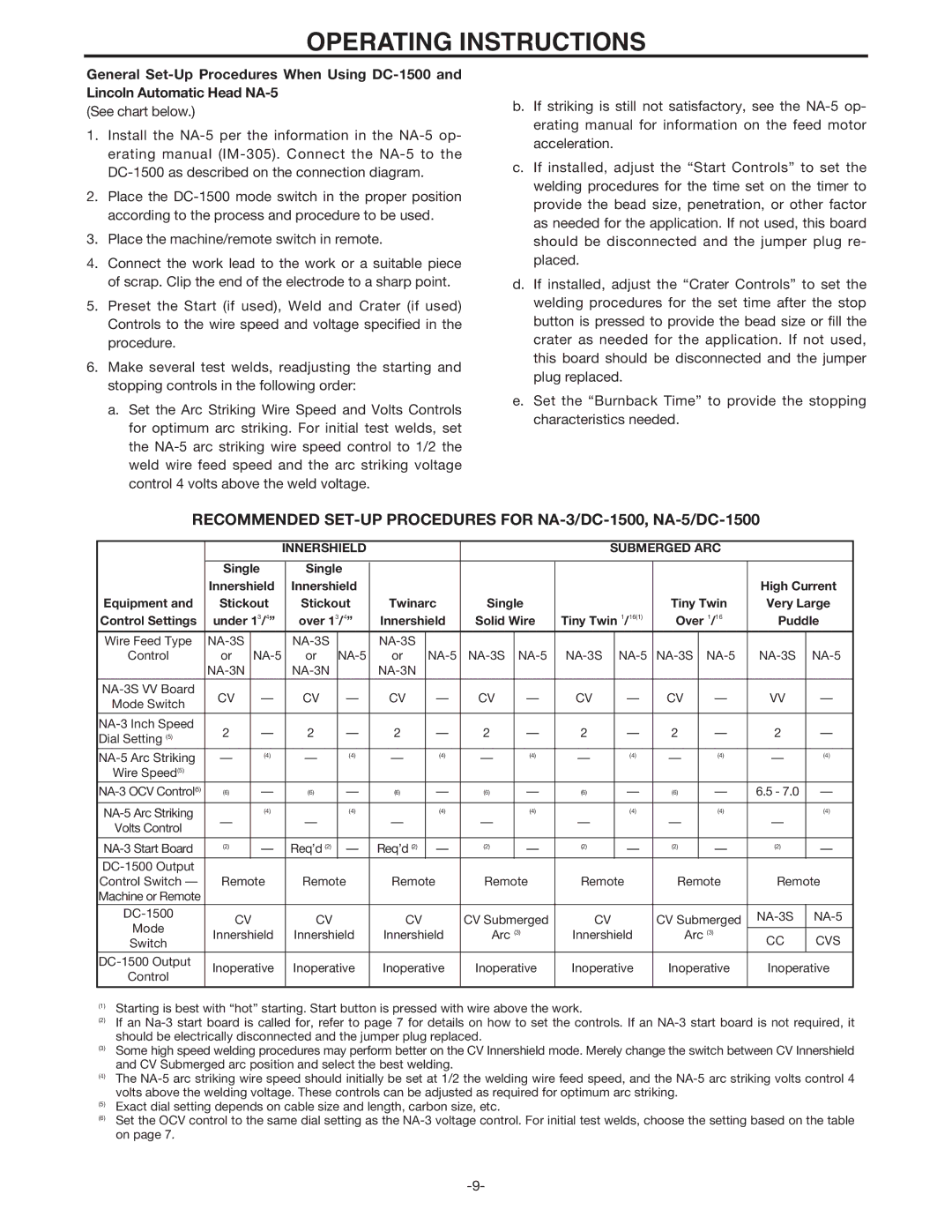

(See chart below.)

1.Install the

2.Place the

3.Place the machine/remote switch in remote.

4.Connect the work lead to the work or a suitable piece of scrap. Clip the end of the electrode to a sharp point.

5.Preset the Start (if used), Weld and Crater (if used) Controls to the wire speed and voltage specified in the procedure.

6.Make several test welds, readjusting the starting and stopping controls in the following order:

a.Set the Arc Striking Wire Speed and Volts Controls for optimum arc striking. For initial test welds, set the

b.If striking is still not satisfactory, see the

c.If installed, adjust the “Start Controls” to set the welding procedures for the time set on the timer to provide the bead size, penetration, or other factor as needed for the application. If not used, this board should be disconnected and the jumper plug re- placed.

d.If installed, adjust the “Crater Controls” to set the welding procedures for the set time after the stop button is pressed to provide the bead size or fill the crater as needed for the application. If not used, this board should be disconnected and the jumper plug replaced.

e.Set the “Burnback Time” to provide the stopping characteristics needed.

RECOMMENDED SET-UP PROCEDURES FOR NA-3/DC-1500, NA-5/DC-1500

|

|

| INNERSHIELD |

|

|

|

|

| SUBMERGED ARC |

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Single |

| Single |

|

|

|

|

|

|

|

|

|

|

| ||

| Innershield |

| Innershield |

|

|

|

|

|

|

|

|

| High Current | |||

Equipment and | Stickout |

| Stickout | Twinarc | Single |

|

|

| Tiny Twin | Very Large | ||||||

Control Settings | under 13/4” |

| over 13/4” | Innershield | Solid Wire | Tiny Twin 1/16(1) | Over 1/16 | Puddle | ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wire Feed Type |

|

|

|

|

|

|

|

|

|

|

|

|

| |||

Control | or |

| or | or |

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

CV | — |

| CV | — | CV | — | CV | — | CV |

| — | CV | — | VV | — | |

Mode Switch |

|

| ||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2 | — |

| 2 | — | 2 | — | 2 | — | 2 |

| — | 2 | — | 2 | — |

Dial Setting (5) |

|

| ||||||||||||||

— | (4) |

| — | (4) | — | (4) | — | (4) | — |

| (4) | — | (4) | — | (4) | |

Wire Speed(5) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(6) | — |

| (6) | — | (6) | — | (6) | — | (6) |

| — | (6) | — | 6.5 - 7.0 | — | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| (4) |

|

| (4) |

| (4) |

| (4) |

|

| (4) |

| (4) |

| (4) | |

Volts Control | — |

|

| — |

| — |

| — |

| — |

|

| — |

| — |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(2) | — |

| Req’d (2) | — | Req’d (2) | — | (2) | — | (2) |

| — | (2) | — | (2) | — | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Control Switch — | Remote |

| Remote | Remote | Remote | Remote | Remote | Remote | ||||||||

Machine or Remote |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CV |

|

| CV |

| CV |

| CV Submerged | CV | CV Submerged | |||||||

Mode | Innershield |

| Innershield | Innershield | Arc (3) | Innershield | Arc (3) |

|

| |||||||

| CC | CVS | ||||||||||||||

Switch |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

Inoperative |

| Inoperative | Inoperative | Inoperative | Inoperative | Inoperative | Inoperative | |||||||||

Control |

| |||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(1)Starting is best with “hot” starting. Start button is pressed with wire above the work.

(2)If an

(3)Some high speed welding procedures may perform better on the CV Innershield mode. Merely change the switch between CV Innershield and CV Submerged arc position and select the best welding.

(4)The

(5)Exact dial setting depends on cable size and length, carbon size, etc.

(6)Set the OCV control to the same dial setting as the