8 | 8 |

Battery Connections

This welder is shipped with the negative battery cable disconnected. Make sure that the Engine Switch is in the “OFF” position and attach the disconnected cable securely to the negative battery terminal before attempting to operate the machine. If the battery is discharged and does not have enough power to start the engine, see the battery charging instructions in the Battery section.

Welding Output Cables

With the engine off, connect the electrode and work cables to the studs provided. These connections should be checked periodically and tightened if neces- sary. Loose connections will result in overheating of the output studs.

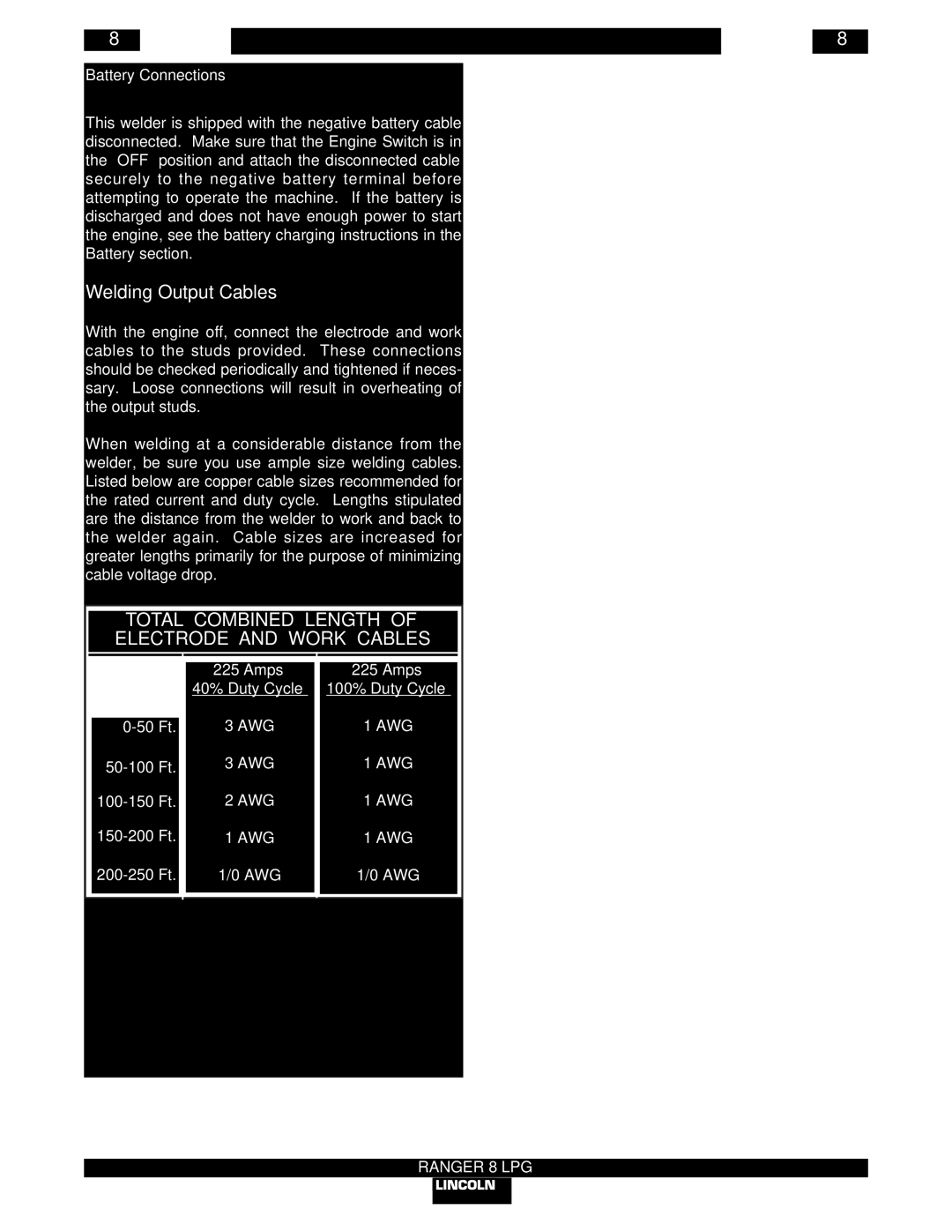

When welding at a considerable distance from the welder, be sure you use ample size welding cables. Listed below are copper cable sizes recommended for the rated current and duty cycle. Lengths stipulated are the distance from the welder to work and back to the welder again. Cable sizes are increased for greater lengths primarily for the purpose of minimizing cable voltage drop.

TOTAL COMBINED LENGTH OF

ELECTRODE AND WORK CABLES

225Amps

40% Duty Cycle

3AWG

3AWG

2AWG

1AWG

225Amps

100% Duty Cycle

1AWG

1AWG

1AWG

1AWG

1/0 AWG

1/0 AWG