| 19 |

|

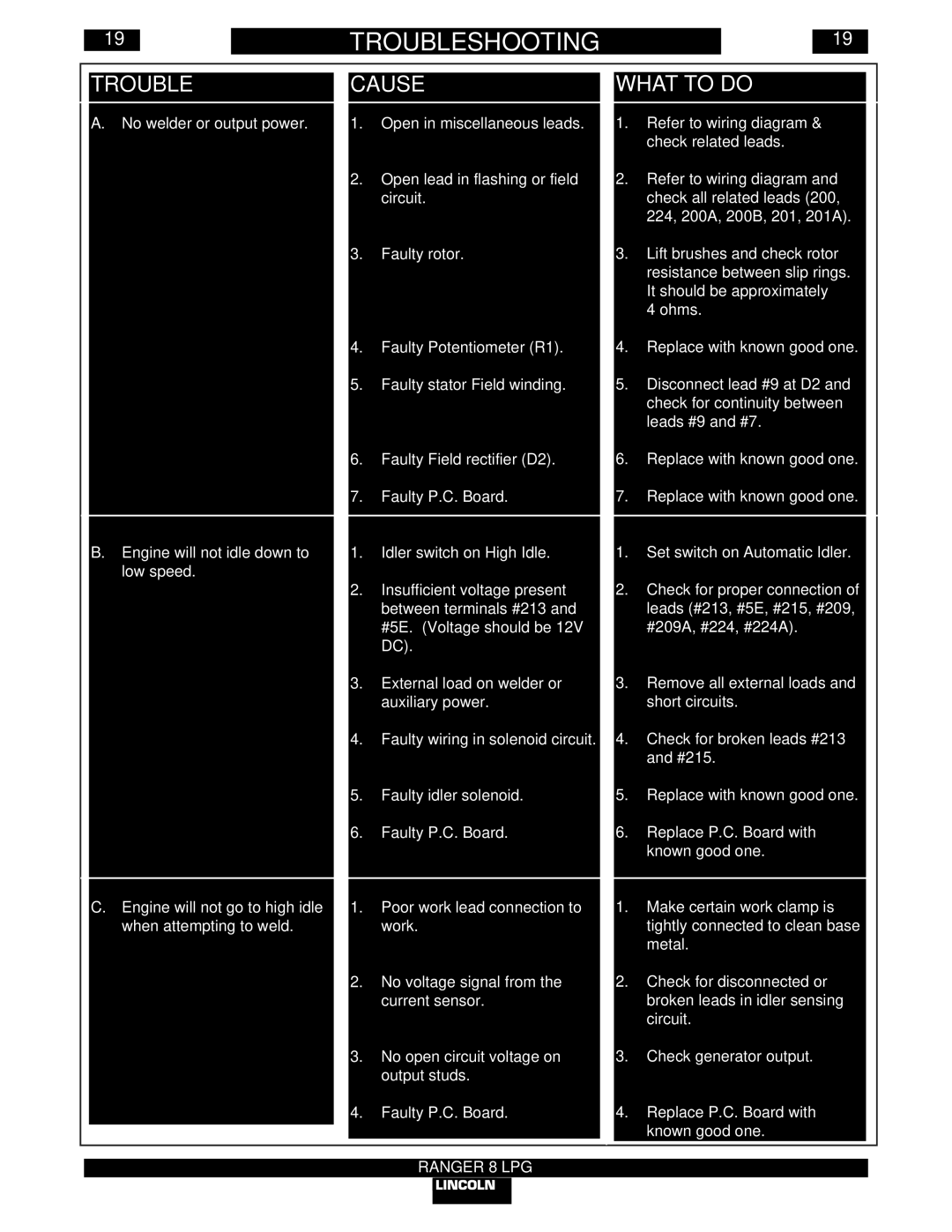

| TROUBLESHOOTING |

| 19 |

|

| ||||

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TROUBLE |

|

| CAUSE |

|

| WHAT TO DO |

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| A. No welder or output power. |

|

| 1. | Open in miscellaneous leads. |

|

| 1. | Refer to wiring diagram & |

|

|

|

|

|

|

|

|

|

|

|

| check related leads. |

|

|

|

|

|

|

| 2. | Open lead in flashing or field |

|

| 2. | Refer to wiring diagram and |

|

|

|

|

|

|

|

| circuit. |

|

|

| check all related leads (200, |

|

|

|

|

|

|

|

|

|

|

|

| 224, 200A, 200B, 201, 201A). |

|

|

|

|

|

|

| 3. | Faulty rotor. |

|

| 3. | Lift brushes and check rotor |

|

|

|

|

|

|

|

|

|

|

|

| resistance between slip rings. |

|

|

|

|

|

|

|

|

|

|

|

| It should be approximately |

|

|

|

|

|

|

|

|

|

|

|

| 4 ohms. |

|

|

|

|

|

|

| 4. | Faulty Potentiometer (R1). |

|

| 4. | Replace with known good one. |

|

|

|

|

|

|

| 5. | Faulty stator Field winding. |

|

| 5. | Disconnect lead #9 at D2 and |

|

|

|

|

|

|

|

|

|

|

|

| check for continuity between |

|

|

|

|

|

|

|

|

|

|

|

| leads #9 and #7. |

|

|

|

|

|

|

| 6. | Faulty Field rectifier (D2). |

|

| 6. | Replace with known good one. |

|

|

|

|

|

|

| 7. | Faulty P.C. Board. |

|

| 7. | Replace with known good one. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| B. Engine will not idle down to |

|

| 1. | Idler switch on High Idle. |

|

| 1. | Set switch on Automatic Idler. |

|

|

|

| low speed. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2. | Insufficient voltage present |

|

| 2. | Check for proper connection of |

|

|

|

|

|

|

|

| between terminals #213 and |

|

|

| leads (#213, #5E, #215, #209, |

|

|

|

|

|

|

|

| #5E. (Voltage should be 12V |

|

|

| #209A, #224, #224A). |

|

|

|

|

|

|

|

| DC). |

|

|

|

|

|

|

|

|

|

|

| 3. | External load on welder or |

|

| 3. | Remove all external loads and |

|

|

|

|

|

|

|

| auxiliary power. |

|

|

| short circuits. |

|

|

|

|

|

|

| 4. | Faulty wiring in solenoid circuit. |

|

| 4. | Check for broken leads #213 |

|

|

|

|

|

|

|

|

|

|

|

| and #215. |

|

|

|

|

|

|

| 5. | Faulty idler solenoid. |

|

| 5. | Replace with known good one. |

|

|

|

|

|

|

| 6. | Faulty P.C. Board. |

|

| 6. | Replace P.C. Board with |

|

|

|

|

|

|

|

|

|

|

|

| known good one. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| C. Engine will not go to high idle |

|

| 1. | Poor work lead connection to |

|

| 1. | Make certain work clamp is |

|

|

|

| when attempting to weld. |

|

|

| work. |

|

|

| tightly connected to clean base |

|

|

|

|

|

|

|

|

|

|

|

| metal. |

|

|

|

|

|

|

| 2. | No voltage signal from the |

|

| 2. | Check for disconnected or |

|

|

|

|

|

|

|

| current sensor. |

|

|

| broken leads in idler sensing |

|

|

|

|

|

|

|

|

|

|

|

| circuit. |

|

|

|

|

|

|

| 3. | No open circuit voltage on |

|

| 3. | Check generator output. |

|

|

|

|

|

|

|

| output studs. |

|

|

|

|

|

|

|

|

|

|

| 4. | Faulty P.C. Board. |

|

| 4. | Replace P.C. Board with |

|

|

|

|

|

|

|

|

|

|

|

| known good one. |

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RANGER 8 LPG |

|

|

|

| ||