INSTALLATION | ||

|

|

|

GENERAL DESCRIPTION

The Tandem MIG torch delivers two wire electrodes to the weld pool. The wires are insulated from each other for the purpose of independent arc regulation. When welding, the wires or arcs are oriented one behind the other. The torch provides a small but rugged housing for delivering the two wires and it provides secure delivery of the shielding gas. Each side of the torch is rated for 450 Amps, 100% duty cycle with argon mix shielding gases.

The 900 amp Tandem MIG torches are supplied in two different configurations, the

The

The torch can be operated

The Tandem MIG torch is not factory equipped with a feeder end connector. Use a

Liners are not included with the torch and must be ordered separately (see ACCESSORIES section).

The torch is suitable for welding with Lincoln solid wire steel MIG wires and metal core electrodes, from .035" to 5/64" (0.9 mm to 1.9 mm) diameter.

Argon based shielding gases are recommended. 100% CO2 is not recommend because of the higher spatter levels associated with the gas.

DESIGN SUMMARY

The case, internal components and cables are the main

TORCH CASE

The case is made from several pieces fabricated from aluminum. The aluminum parts offer rigidity, strength and resistance to heat and spatter. The main housing is drilled and tapped for easy mounting to fixturing equipment. For automation and robotic applications, the barrel of the torch is removable and replaceable without having an effect upon the existing tool center point.

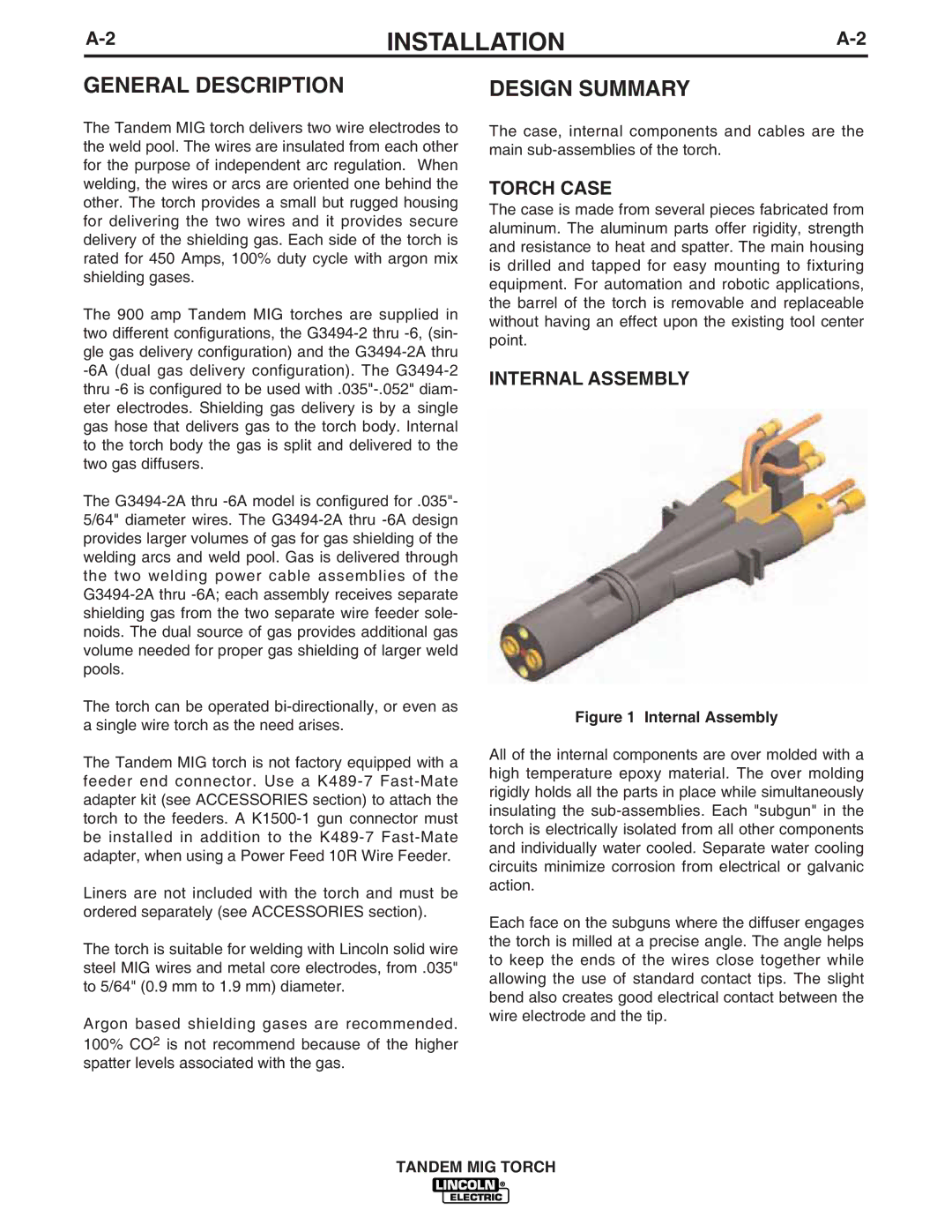

INTERNAL ASSEMBLY

Figure 1 Internal Assembly

All of the internal components are over molded with a high temperature epoxy material. The over molding rigidly holds all the parts in place while simultaneously insulating the

Each face on the subguns where the diffuser engages the torch is milled at a precise angle. The angle helps to keep the ends of the wires close together while allowing the use of standard contact tips. The slight bend also creates good electrical contact between the wire electrode and the tip.

TANDEM MIG TORCH