MAINTENANCE | ||

|

|

|

SAFETY PRECAUTIONS

![]() WARNING

WARNING

Have qualified personnel do the maintenance work. If a problem cannot be corrected by following the instructions, take the equipment to the nearest Lincoln Field Service Shop for repair.

ELECTRIC SHOCK can kill.

•Do not touch electrically live parts or electrode with skin or wet clothing.

•Insulate yourself from work and ground

•Always wear dry insulating gloves.

See additional warning information throughout this operator’s manual.

MAINTENANCE

a)Replace worn contact tips as required.

b)Remove spatter from inside of the gas nozzle and from the tips after every 20 minutes of arc time, or as required.

c)Replace the nozzle shield when it exhibits signs of deterioration.

d)For steel or metal cored electrodes, clean the cable liners after using approximately 2000 lbs of electrode. Remove the cables from the wire feeders and extend them so they are straight. Lay the cables out on the floor, if possible. Remove the contact tips from the torch. Using an air hose and only partial pressure, gently blow out the cable liners from the gas diffuser end. Flex the cables over its entire length and again blow out the cable. Repeat this procedure until no further dirt comes out.

![]() CAUTION

CAUTION

EXCESSIVE PRESSURE MAY CAUSE THE DIRT

TO FORM A PLUG.

TORCH SHIELD REPLACEMENT

It is important that the torch shield be inspected and replaced on a routine basis. The torch shields (S24432,

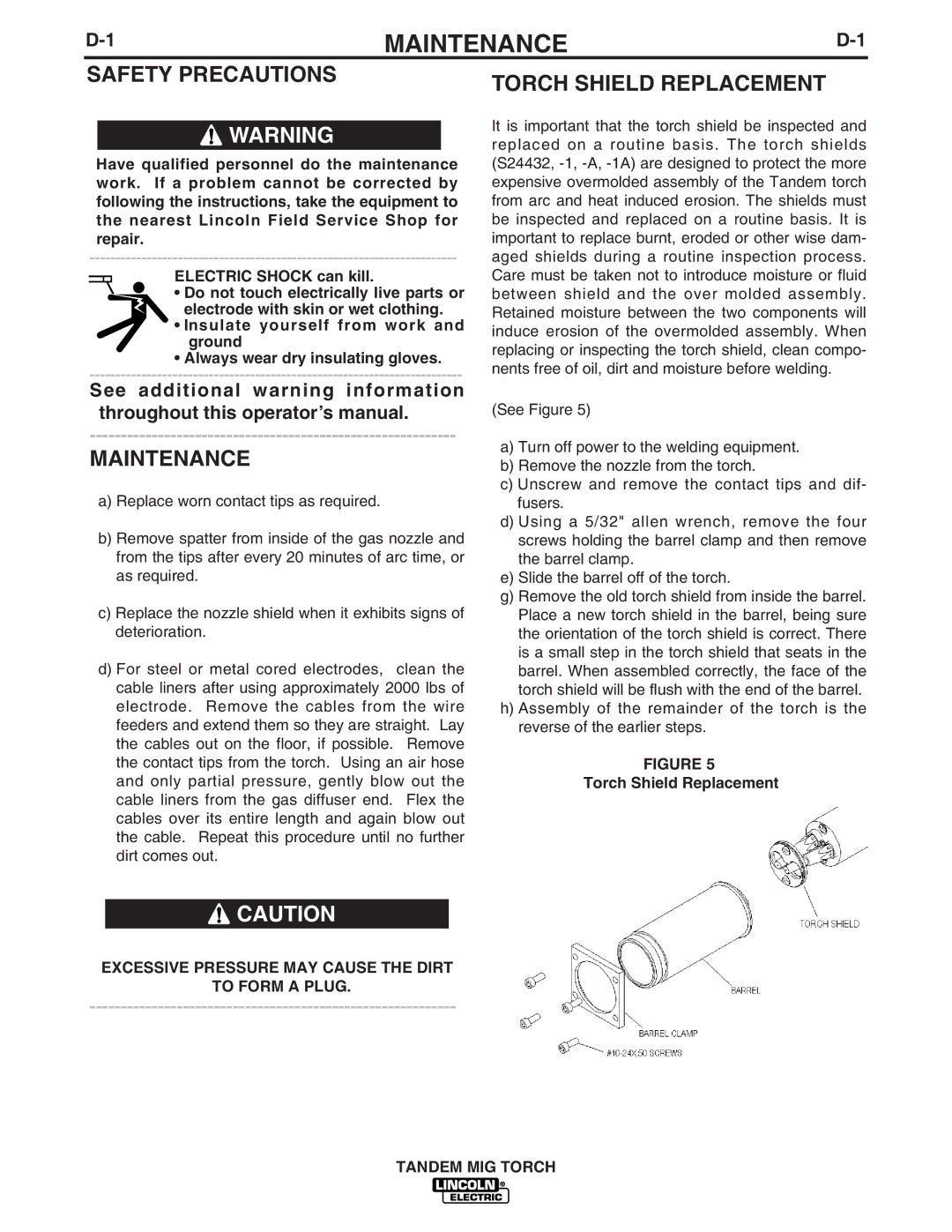

(See Figure 5)

a)Turn off power to the welding equipment.

b)Remove the nozzle from the torch.

c)Unscrew and remove the contact tips and dif- fusers.

d)Using a 5/32" allen wrench, remove the four screws holding the barrel clamp and then remove the barrel clamp.

e)Slide the barrel off of the torch.

g)Remove the old torch shield from inside the barrel. Place a new torch shield in the barrel, being sure the orientation of the torch shield is correct. There is a small step in the torch shield that seats in the barrel. When assembled correctly, the face of the torch shield will be flush with the end of the barrel.

h)Assembly of the remainder of the torch is the reverse of the earlier steps.

FIGURE 5

Torch Shield Replacement

TANDEM MIG TORCH