TROUBLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

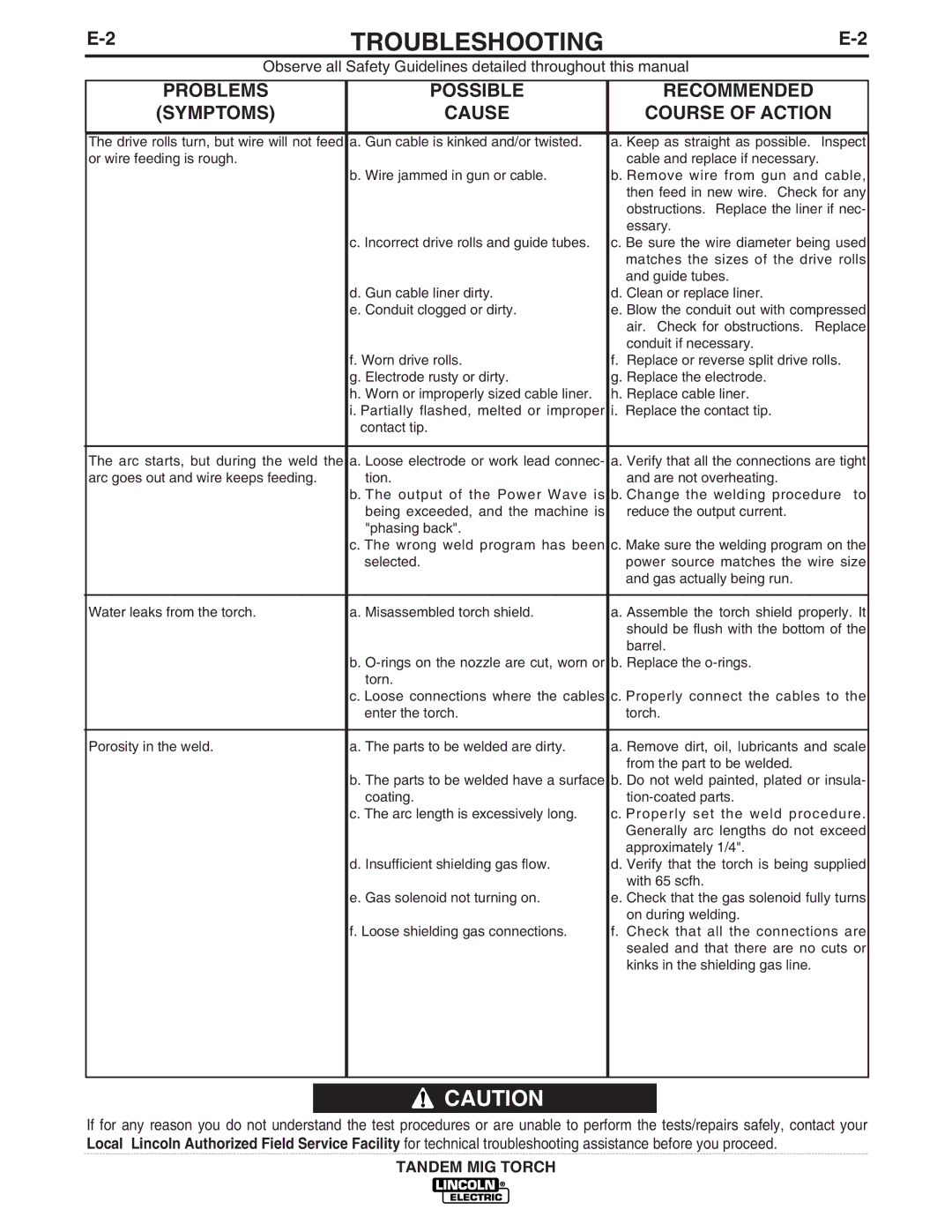

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

The drive rolls turn, but wire will not feed | a. Gun cable is kinked and/or twisted. | a. Keep as straight as possible. Inspect |

or wire feeding is rough. |

| cable and replace if necessary. |

| b. Wire jammed in gun or cable. | b. Remove wire from gun and cable, |

|

| then feed in new wire. Check for any |

|

| obstructions. Replace the liner if nec- |

|

| essary. |

| c. Incorrect drive rolls and guide tubes. | c. Be sure the wire diameter being used |

|

| matches the sizes of the drive rolls |

|

| and guide tubes. |

| d. Gun cable liner dirty. | d. Clean or replace liner. |

| e. Conduit clogged or dirty. | e. Blow the conduit out with compressed |

|

| air. Check for obstructions. Replace |

|

| conduit if necessary. |

| f. Worn drive rolls. | f. Replace or reverse split drive rolls. |

| g. Electrode rusty or dirty. | g. Replace the electrode. |

| h. Worn or improperly sized cable liner. | h. Replace cable liner. |

| i. Partially flashed, melted or improper | i. Replace the contact tip. |

| contact tip. |

|

|

|

|

The arc starts, but during the weld the | a. Loose electrode or work lead connec- | a. Verify that all the connections are tight |

arc goes out and wire keeps feeding. | tion. | and are not overheating. |

| b. The output of the Power Wave is | b. Change the welding procedure to |

| being exceeded, and the machine is | reduce the output current. |

| "phasing back". |

|

| c. The wrong weld program has been | c. Make sure the welding program on the |

| selected. | power source matches the wire size |

|

| and gas actually being run. |

|

|

|

Water leaks from the torch. | a. Misassembled torch shield. | a. Assemble the torch shield properly. It |

|

| should be flush with the bottom of the |

|

| barrel. |

| b. | b. Replace the |

| torn. |

|

| c. Loose connections where the cables | c. Properly connect the cables to the |

| enter the torch. | torch. |

|

|

|

Porosity in the weld. | a. The parts to be welded are dirty. | a. Remove dirt, oil, lubricants and scale |

|

| from the part to be welded. |

| b. The parts to be welded have a surface | b. Do not weld painted, plated or insula- |

| coating. | |

| c. The arc length is excessively long. | c. Properly set the weld procedure. |

|

| Generally arc lengths do not exceed |

|

| approximately 1/4". |

| d. Insufficient shielding gas flow. | d. Verify that the torch is being supplied |

|

| with 65 scfh. |

| e. Gas solenoid not turning on. | e. Check that the gas solenoid fully turns |

|

| on during welding. |

| f. Loose shielding gas connections. | f. Check that all the connections are |

|

| sealed and that there are no cuts or |

|

| kinks in the shielding gas line. |

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

TANDEM MIG TORCH