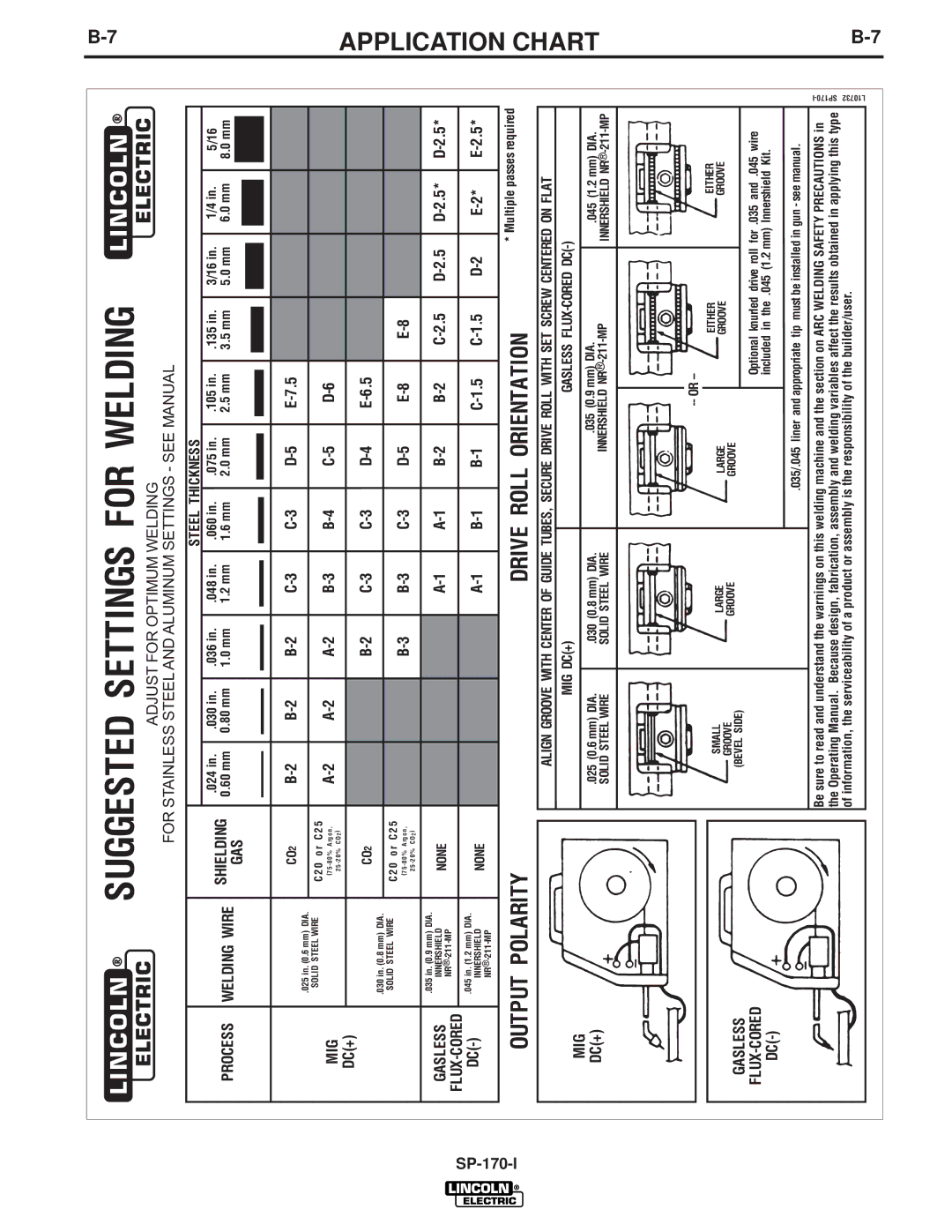

SUGGESTED SETTINGS FOR WELDING

ADJUST FOR OPTIMUM WELDING

FOR STAINLESS STEEL AND ALUMINUM SETTINGS - SEE MANUAL

|

|

|

|

|

|

|

|

| STEEL THICKNESS |

|

|

|

|

|

|

|

|

|

| |||

| SHIELDING | .024 in. | .030 in. | .036 in. |

| .048 in. |

| .060 in. |

| .075 in. |

| .105 in. |

| .135 in. |

| 3/16 in. |

| 1/4 in. | 5/16 | |||

PROCESS WELDING WIRE | 0.60 mm | 0.80 mm | 1.0 mm |

| 1.2 mm |

| 1.6 mm |

| 2.0 mm |

| 2.5 mm |

| 3.5 mm |

| 5.0 mm |

| 6.0 mm |

| 8.0 mm | |||

GAS |

|

|

|

|

|

|

|

| ||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| .025 in. (0.6 mm) DIA. | CO2 |

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

MIG | SOLID STEEL WIRE | C 2 0 o r | C 2 5 |

|

|

|

| |||||||

| 2 5 | C O2 ) |

|

|

|

| ||||||||

|

| (7 5 |

|

|

|

|

|

|

|

|

|

|

| |

DC(+) |

|

|

|

|

|

|

|

|

| |||||

| .030 in. (0.8 mm) DIA. | CO2 |

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| SOLID STEEL WIRE | C 2 0 o r | C 2 5 |

|

|

|

|

| ||||||

|

| (7 5 |

|

|

|

|

| |||||||

|

| 2 5 | C O2 ) |

|

|

|

|

|

|

|

|

|

|

|

GASLESS | .035 in. (0.9 mm) DIA. | NONE |

|

|

| |||||||||

INNERSHIELD |

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

.045 in. (1.2 mm) DIA. |

|

|

|

|

|

|

|

|

|

|

|

|

| |

NONE |

|

|

| |||||||||||

INNERSHIELD |

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

OUTPUT POLARITY |

|

|

|

| DRIVE ROLL ORIENTATION |

| * Multiple passes required | |||||||

|

|

|

|

|

|

| ||||||||

|

|

|

| ALIGN GROOVE WITH CENTER OF GUIDE TUBES, SECURE DRIVE ROLL WITH SET SCREW CENTERED ON FLAT |

| |||||||||

MIG |

|

|

|

| MIG DC(+) |

|

|

| GASLESS |

| ||||

|

|

| .025 (0.6 mm) DIA. | .030 (0.8 mm) DIA. |

|

| .035 (0.9 mm) DIA. |

| .045 (1.2 mm) DIA. | |||||

DC(+) |

|

|

|

|

|

| ||||||||

|

|

|

| SOLID STEEL WIRE | SOLID STEEL WIRE |

| INNERSHIELD |

| INNERSHIELD | |||||

|

|

|

|

|

|

| ||

| SMALL | LARGE |

|

|

| EITHER | EITHER |

|

|

|

|

|

| ||||

| LARGE |

|

| GROOVE | GROOVE |

| ||

GASLESS | GROOVE | GROOVE | GROOVE |

|

|

|

|

|

(BEVEL SIDE) |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| ||

|

|

|

| Optional knurled drive roll for .035 and .045 wire |

| |||

|

|

|

| included in the .045 (1.2 mm) Innershield Kit. |

| |||

|

|

|

|

|

|

|

| |

|

|

| .035/.045 liner and appropriate tip must be installed in gun - see manual. |

| ||||

| Be sure to read and understand the warnings on this welding machine and the section on ARC WELDING SAFETY PRECAUTIONS in | |||||||

| SP170 | |||||||

| the Operating Manual. Because design, fabrication, assembly and welding variables affect the results obtained in applying this type | |||||||

|

| |||||||

| of information, the serviceability of a product or assembly is the responsibility of the builder/user. |

| L10732 | |||||

|

|

|

|

|

|

|

| |