OPERATION |

TYPICAL FUEL CONSUMPTION

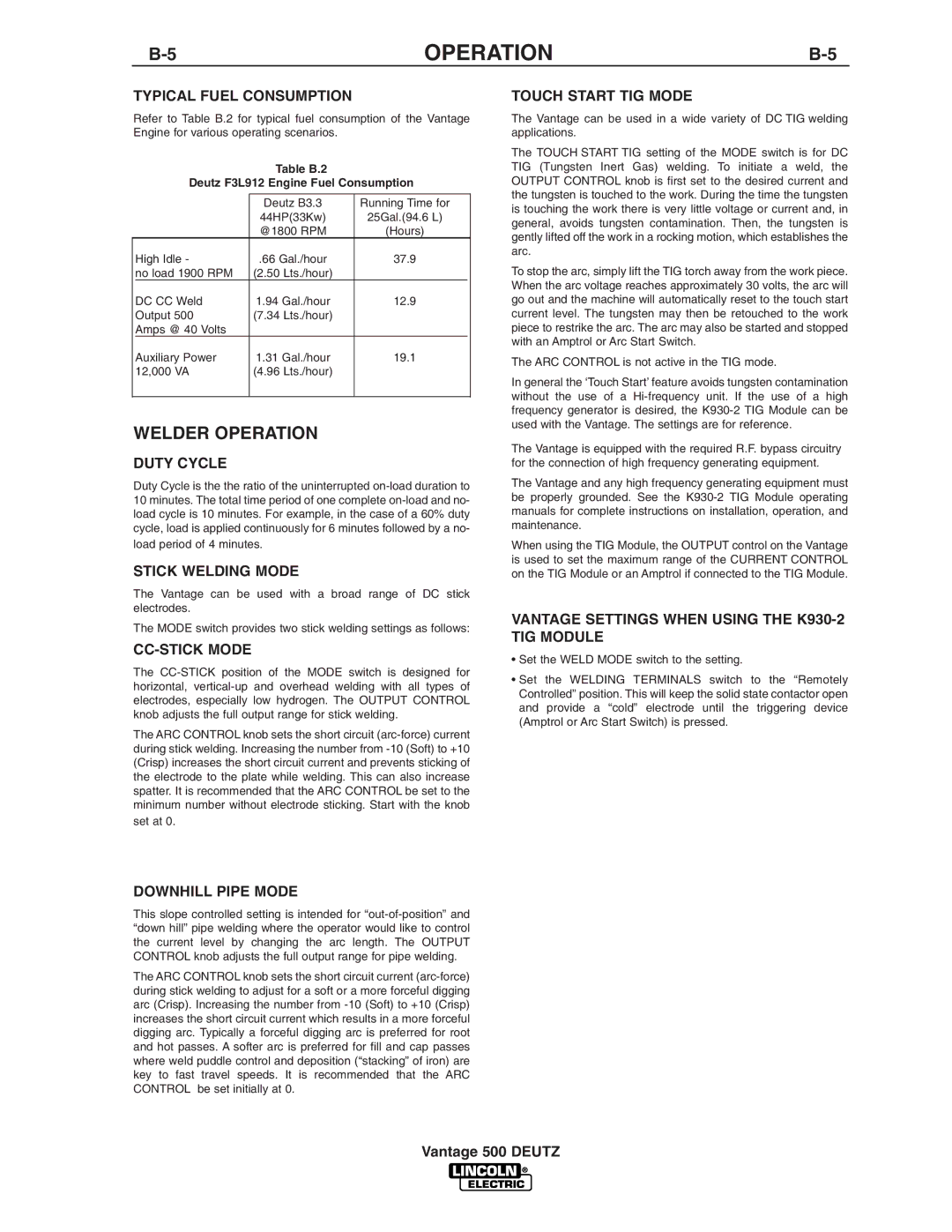

Refer to Table B.2 for typical fuel consumption of the Vantage Engine for various operating scenarios.

Table B.2

Deutz F3L912 Engine Fuel Consumption

|

| Deutz B3.3 | Running Time for |

|

|

| 44HP(33Kw) | 25Gal.(94.6 L) |

|

|

| @1800 RPM | (Hours) |

|

| High Idle - | .66 Gal./hour | 37.9 |

|

| no load 1900 RPM | (2.50 Lts./hour) |

|

|

| DC CC Weld | 1.94 Gal./hour | 12.9 |

|

| Output 500 | (7.34 Lts./hour) |

|

|

| Amps @ 40 Volts |

|

|

|

| Auxiliary Power | 1.31 Gal./hour | 19.1 |

|

| 12,000 VA | (4.96 Lts./hour) |

|

|

|

|

|

|

|

WELDER OPERATION

DUTY CYCLE

Duty Cycle is the the ratio of the uninterrupted

STICK WELDING MODE

The Vantage can be used with a broad range of DC stick electrodes.

The MODE switch provides two stick welding settings as follows:

CC-STICK MODE

The

The ARC CONTROL knob sets the short circuit

DOWNHILL PIPE MODE

This slope controlled setting is intended for

The ARC CONTROL knob sets the short circuit current

TOUCH START TIG MODE

The Vantage can be used in a wide variety of DC TIG welding applications.

The TOUCH START TIG setting of the MODE switch is for DC TIG (Tungsten Inert Gas) welding. To initiate a weld, the OUTPUT CONTROL knob is first set to the desired current and the tungsten is touched to the work. During the time the tungsten is touching the work there is very little voltage or current and, in general, avoids tungsten contamination. Then, the tungsten is gently lifted off the work in a rocking motion, which establishes the arc.

To stop the arc, simply lift the TIG torch away from the work piece. When the arc voltage reaches approximately 30 volts, the arc will go out and the machine will automatically reset to the touch start current level. The tungsten may then be retouched to the work piece to restrike the arc. The arc may also be started and stopped with an Amptrol or Arc Start Switch.

The ARC CONTROL is not active in the TIG mode.

In general the ‘Touch Start’ feature avoids tungsten contamination without the use of a

The Vantage is equipped with the required R.F. bypass circuitry for the connection of high frequency generating equipment.

The Vantage and any high frequency generating equipment must be properly grounded. See the

When using the TIG Module, the OUTPUT control on the Vantage is used to set the maximum range of the CURRENT CONTROL on the TIG Module or an Amptrol if connected to the TIG Module.

VANTAGE SETTINGS WHEN USING THE K930-2 TIG MODULE

•Set the WELD MODE switch to the setting.

•Set the WELDING TERMINALS switch to the “Remotely Controlled” position. This will keep the solid state contactor open and provide a “cold” electrode until the triggering device (Amptrol or Arc Start Switch) is pressed.

Vantage 500 DEUTZ