| OPERATION | ||

|

|

|

|

| “ | RANGE” SWITCH |

|

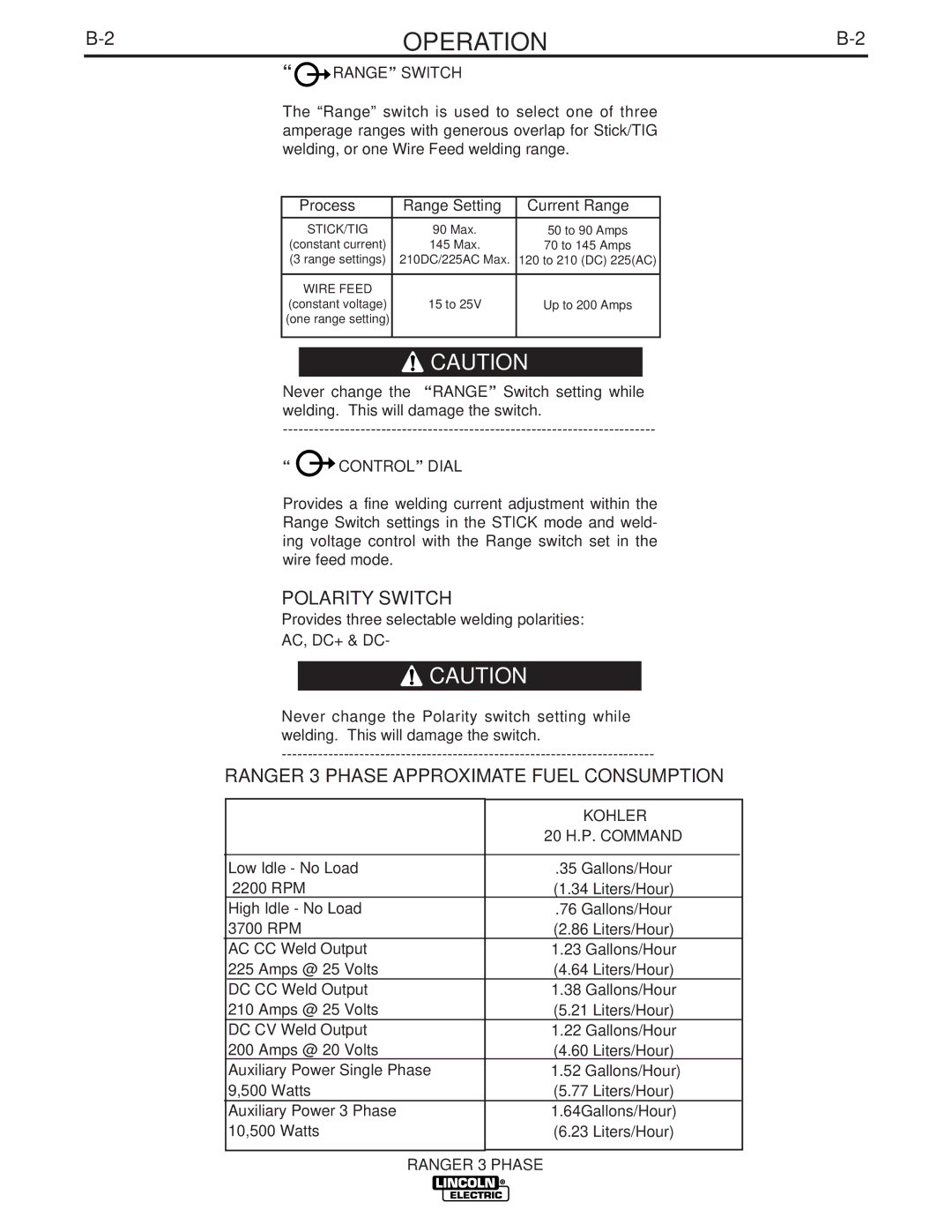

The “Range” switch is used to select one of three amperage ranges with generous overlap for Stick/TIG welding, or one Wire Feed welding range.

Process | Range Setting | Current Range | |

|

|

| |

STICK/TIG | |||

90 Max. | |||

50 to 90 Amps | |||

(constant current) | 145 Max. | 70 to 145 Amps | |

(3 range settings) | 210DC/225AC Max. | 120 to 210 (DC) 225(AC) | |

|

|

| |

WIRE FEED |

|

| |

(constant voltage) | 15 to 25V | Up to 200 Amps | |

(one range setting) |

|

| |

|

|

| |

|

|

|

![]() CAUTION

CAUTION

Never change the “RANGE” Switch setting while welding. This will damage the switch.

“ CONTROL” DIAL

CONTROL” DIAL

Provides a fine welding current adjustment within the Range Switch settings in the STICK mode and weld- ing voltage control with the Range switch set in the wire feed mode.

POLARITY SWITCH

Provides three selectable welding polarities:

AC, DC+ & DC-

![]() CAUTION

CAUTION

Never change the Polarity switch setting while welding. This will damage the switch.

RANGER 3 PHASE APPROXIMATE FUEL CONSUMPTION

| KOHLER | |

| 20 H.P. COMMAND | |

|

|

|

Low Idle - No Load | .35 Gallons/Hour | |

2200 RPM | (1.34 Liters/Hour) | |

High Idle - No Load | .76 Gallons/Hour | |

3700 RPM | (2.86 Liters/Hour) | |

AC CC Weld Output | 1.23 Gallons/Hour | |

225 Amps @ 25 Volts | (4.64 Liters/Hour) | |

DC CC Weld Output | 1.38 Gallons/Hour | |

210 Amps @ 25 Volts | (5.21 Liters/Hour) | |

DC CV Weld Output | 1.22 Gallons/Hour | |

200 Amps @ 20 Volts | (4.60 Liters/Hour) | |

Auxiliary Power Single Phase | 1.52 Gallons/Hour) | |

9,500 Watts | (5.77 Liters/Hour) | |

Auxiliary Power 3 Phase | 1.64Gallons/Hour) | |

10,500 Watts | (6.23 Liters/Hour) | |

|

|

|