| TROUBLESHOOTING |

| ||||

|

|

|

|

|

|

|

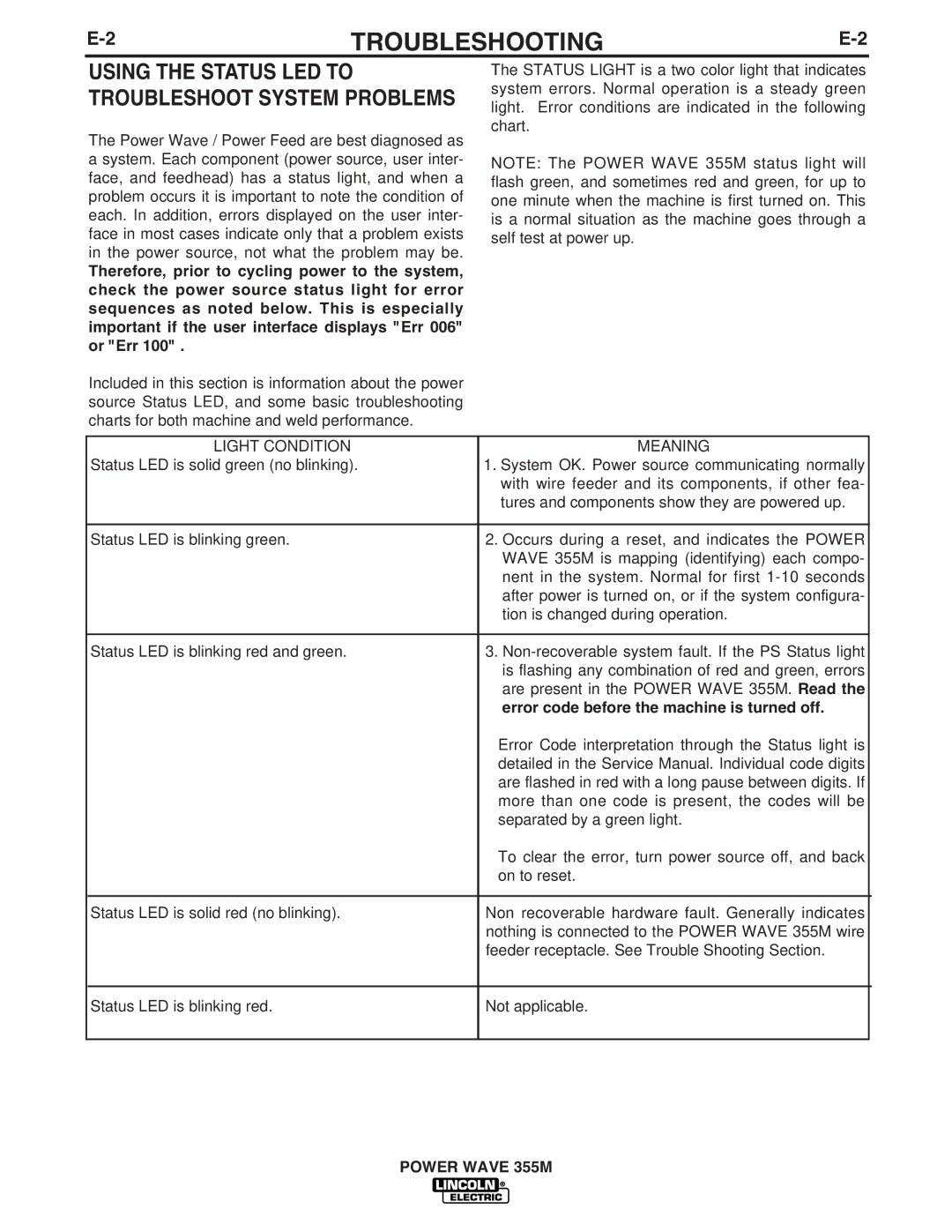

| USING THE STATUS LED TO | The STATUS LIGHT is a two color light that indicates |

| |||

| TROUBLESHOOT SYSTEM PROBLEMS | system errors. Normal operation is a steady green |

| |||

| light. Error conditions are indicated in the following |

| ||||

|

|

|

|

| ||

| The Power Wave / Power Feed are best diagnosed as | chart. |

|

| ||

|

|

|

| |||

| a system. Each component (power source, user inter- | NOTE: The POWER WAVE 355M status light will |

| |||

| face, and feedhead) has a status light, and when a | flash green, and sometimes red and green, for up to |

| |||

| problem occurs it is important to note the condition of | one minute when the machine is first turned on. This |

| |||

| each. In addition, errors displayed on the user inter- | is a normal situation as the machine goes through a |

| |||

| face in most cases indicate only that a problem exists | self test at power up. |

|

| ||

| in the power source, not what the problem may be. |

|

|

| ||

| Therefore, prior to cycling power to the system, |

|

|

| ||

| check the power source status light for error |

|

|

| ||

| sequences as noted below. This is especially |

|

|

| ||

| important if the user interface displays "Err 006" |

|

|

| ||

| or "Err 100" . |

|

|

|

| |

| Included in this section is information about the power |

|

|

| ||

| source Status LED, and some basic troubleshooting |

|

|

| ||

| charts for both machine and weld performance. |

|

|

| ||

|

|

|

|

|

| |

|

| LIGHT CONDITION | MEANING |

|

| |

| Status LED is solid green (no blinking). | 1. System OK. Power source communicating normally |

| |||

|

|

|

| with wire feeder and its components, if other fea- |

| |

|

|

|

| tures and components show they are powered up. |

| |

|

|

|

|

| ||

| Status LED is blinking green. |

| 2. Occurs during a reset, and indicates the POWER |

| ||

|

|

|

| WAVE 355M is mapping (identifying) each compo- |

| |

|

|

|

| nent in the system. Normal for first |

| |

|

|

|

| after power is turned on, or if the system configura- |

| |

|

|

|

| tion is changed during operation. |

|

|

|

|

|

|

| ||

| Status LED is blinking red and green. |

| 3. |

| ||

|

|

|

| is flashing any combination of red and green, errors |

| |

|

|

|

| are present in the POWER WAVE 355M. Read the |

| |

|

|

|

| error code before the machine is turned off. |

|

|

|

|

|

| Error Code interpretation through the Status light is |

| |

|

|

|

| detailed in the Service Manual. Individual code digits |

| |

|

|

|

| are flashed in red with a long pause between digits. If |

| |

|

|

|

| more than one code is present, the codes will be |

| |

|

|

|

| separated by a green light. |

|

|

|

|

|

| To clear the error, turn power source off, and back |

| |

|

|

|

| on to reset. |

|

|

|

|

|

|

| ||

| Status LED is solid red (no blinking). |

| Non recoverable hardware fault. Generally indicates |

| ||

|

|

|

| nothing is connected to the POWER WAVE 355M wire |

| |

|

|

|

| feeder receptacle. See Trouble Shooting Section. |

|

|

Status LED is blinking red.

Not applicable.

POWER WAVE 355M