OPERATION | ||

|

|

|

![]() CAUTION

CAUTION

Operating the starter motor for more than 5 sec- onds can damage the motor. If the engine fails to start, release the switch and wait 10 seconds before operation the starter again. Do NOT push the START button while the engine is running because this can damage the ring gear and/or the starter motor.

STOPPING

Remove all welding and auxiliary power loads and allow the engine to run at low idle speed for a few minutes to cool the engine.

Stop the engine by placing the

Note: The engine will run for a breif moment (3 to 5 seconds) while the excess fuel is burned out of the system.

WELDER OPERATION

DUTY CYCLE

Duty Cycle is the percentage of time the load is being applied in a 10 minute period. For example, a 60% duty cycle represents 6 minutes of load and 4 minutes of no load in a 10 minute period.

DC Stick Welding

The RANGER 250 LPG can be used with a broad range of DC stick electrodes.

The MODE switch provides two stick welding settings as follows:

Constant Current (CC-STICK) Welding

The

The ARC CONTROL dial sets the short circuit current

DOWNHILL PIPE Welding

This slope controlled setting is intended for

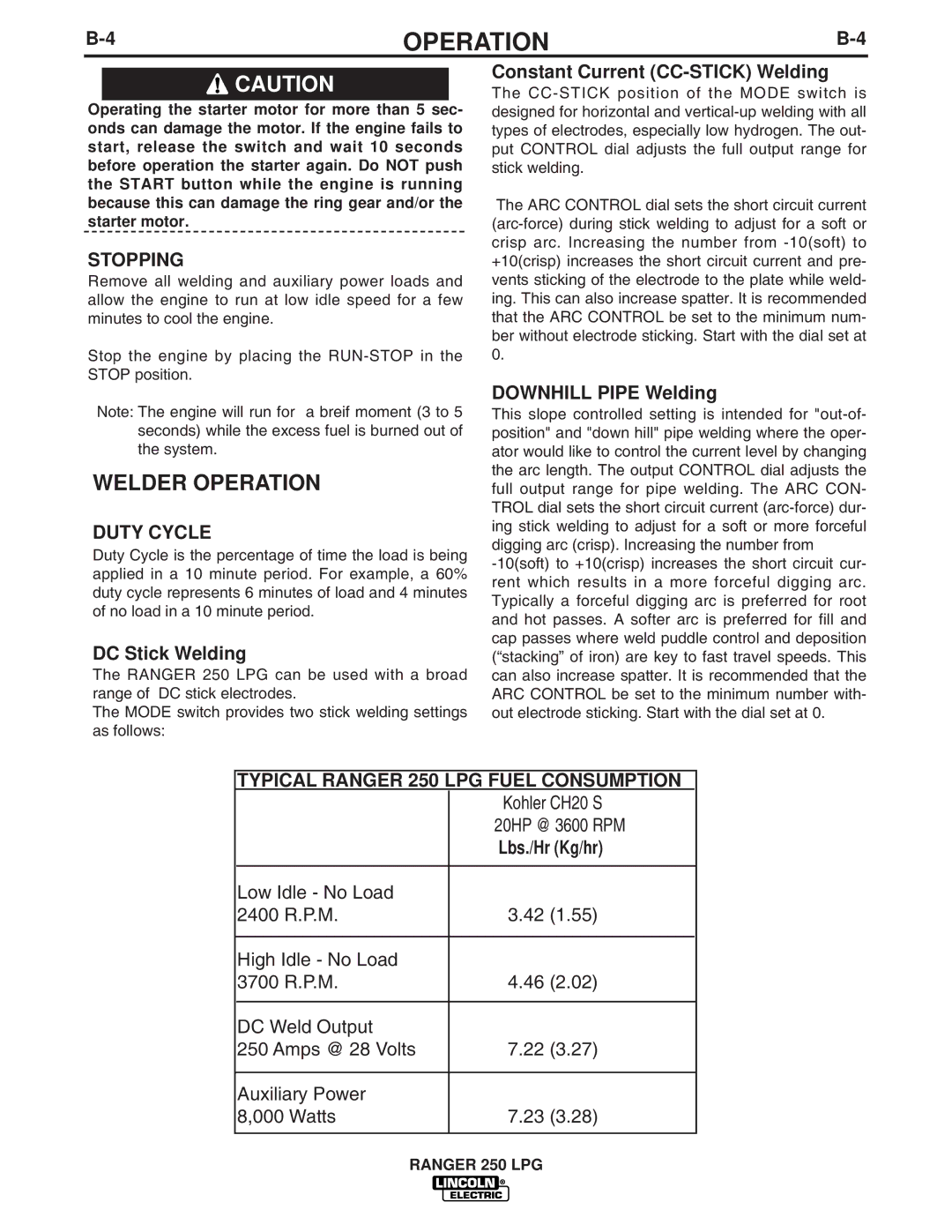

TYPICAL RANGER 250 LPG FUEL CONSUMPTION

|

| Kohler CH20 S | |

|

| 20HP @ 3600 RPM | |

|

| Lbs./Hr (Kg/hr) | |

|

|

|

|

| Low Idle - No Load |

|

|

| 2400 R.P.M. | 3.42 (1.55) |

|

|

|

|

|

| High Idle - No Load |

|

|

| 3700 R.P.M. | 4.46 (2.02) |

|

|

|

|

|

| DC Weld Output |

|

|

| 250 Amps @ 28 Volts | 7.22 (3.27) |

|

|

|

|

|

| Auxiliary Power |

|

|

| 8,000 Watts | 7.23 (3.28) |

|

|

|

|

|

RANGER 250 LPG