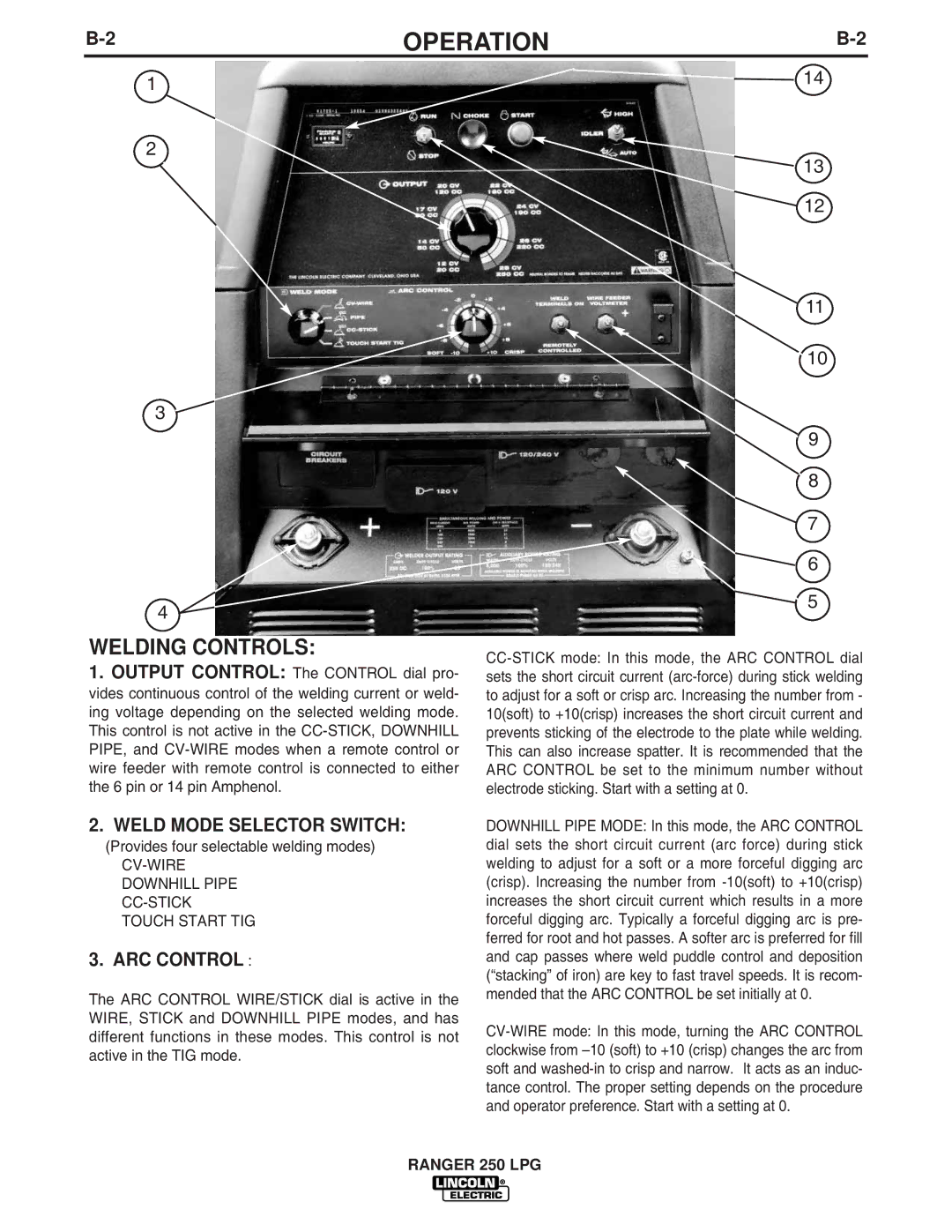

OPERATION | ||

|

|

|

1

2

3

4

WELDING CONTROLS:

1.OUTPUT CONTROL: The CONTROL dial pro- vides continuous control of the welding current or weld- ing voltage depending on the selected welding mode. This control is not active in the

2.WELD MODE SELECTOR SWITCH:

(Provides four selectable welding modes)

3.ARC CONTROL :

The ARC CONTROL WIRE/STICK dial is active in the WIRE, STICK and DOWNHILL PIPE modes, and has different functions in these modes. This control is not active in the TIG mode.

![]() 14

14

![]() 13

13

![]() 12

12

11

10

9

8

7

6

5

DOWNHILL PIPE MODE: In this mode, the ARC CONTROL dial sets the short circuit current (arc force) during stick welding to adjust for a soft or a more forceful digging arc (crisp). Increasing the number from

RANGER 250 LPG