| OPERATION |

| ||

Friction Brake Adjustment |

| FIGURE B.4 | ||

|

|

| ||

With wire spool installed on the spindle shaft and the wing nut loose, turn the spool by hand while slowly tightening the wing nut until a light drag is felt. Tighten the wing nut an additional 1/4 turn.

Note: When properly adjusted, the brake should pro- vide only enough drag to prevent overrun of the spool and excess slack in the wire. Too much drag may result in wire feeding problems, and may cause pre- mature wear of wire drive system components.

Wire Threading

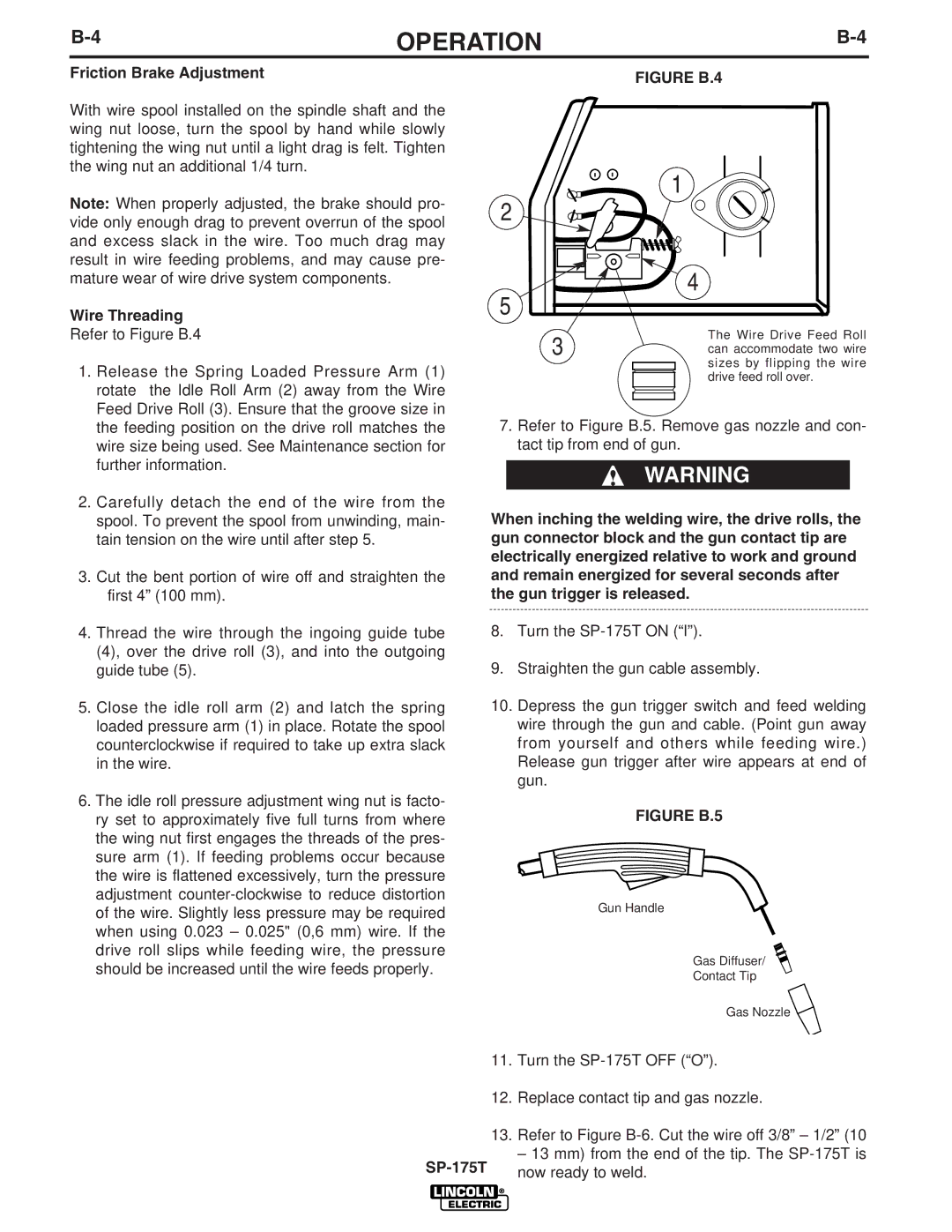

Refer to Figure B.4

1.Release the Spring Loaded Pressure Arm (1) rotate the Idle Roll Arm (2) away from the Wire Feed Drive Roll (3). Ensure that the groove size in the feeding position on the drive roll matches the wire size being used. See Maintenance section for further information.

2.Carefully detach the end of the wire from the spool. To prevent the spool from unwinding, main- tain tension on the wire until after step 5.

3.Cut the bent portion of wire off and straighten the first 4” (100 mm).

4.Thread the wire through the ingoing guide tube (4), over the drive roll (3), and into the outgoing guide tube (5).

5.Close the idle roll arm (2) and latch the spring loaded pressure arm (1) in place. Rotate the spool counterclockwise if required to take up extra slack in the wire.

6.The idle roll pressure adjustment wing nut is facto- ry set to approximately five full turns from where the wing nut first engages the threads of the pres- sure arm (1). If feeding problems occur because the wire is flattened excessively, turn the pressure adjustment

1

2

5 | 4 |

| |

3 | The Wire Drive Feed Roll |

can accommodate two wire |

sizes by flipping the wire drive feed roll over.

7.Refer to Figure B.5. Remove gas nozzle and con- tact tip from end of gun.

WARNING

When inching the welding wire, the drive rolls, the gun connector block and the gun contact tip are electrically energized relative to work and ground and remain energized for several seconds after the gun trigger is released.

8.Turn the

9.Straighten the gun cable assembly.

10.Depress the gun trigger switch and feed welding wire through the gun and cable. (Point gun away from yourself and others while feeding wire.) Release gun trigger after wire appears at end of gun.

FIGURE B.5

Gun Handle

Gas Diffuser/

Contact Tip

Gas Nozzle ![]()

11.Turn the

12.Replace contact tip and gas nozzle.

13.Refer to Figure

– 13 mm) from the end of the tip. The

| now ready to weld. |

|