MIG WELDERS

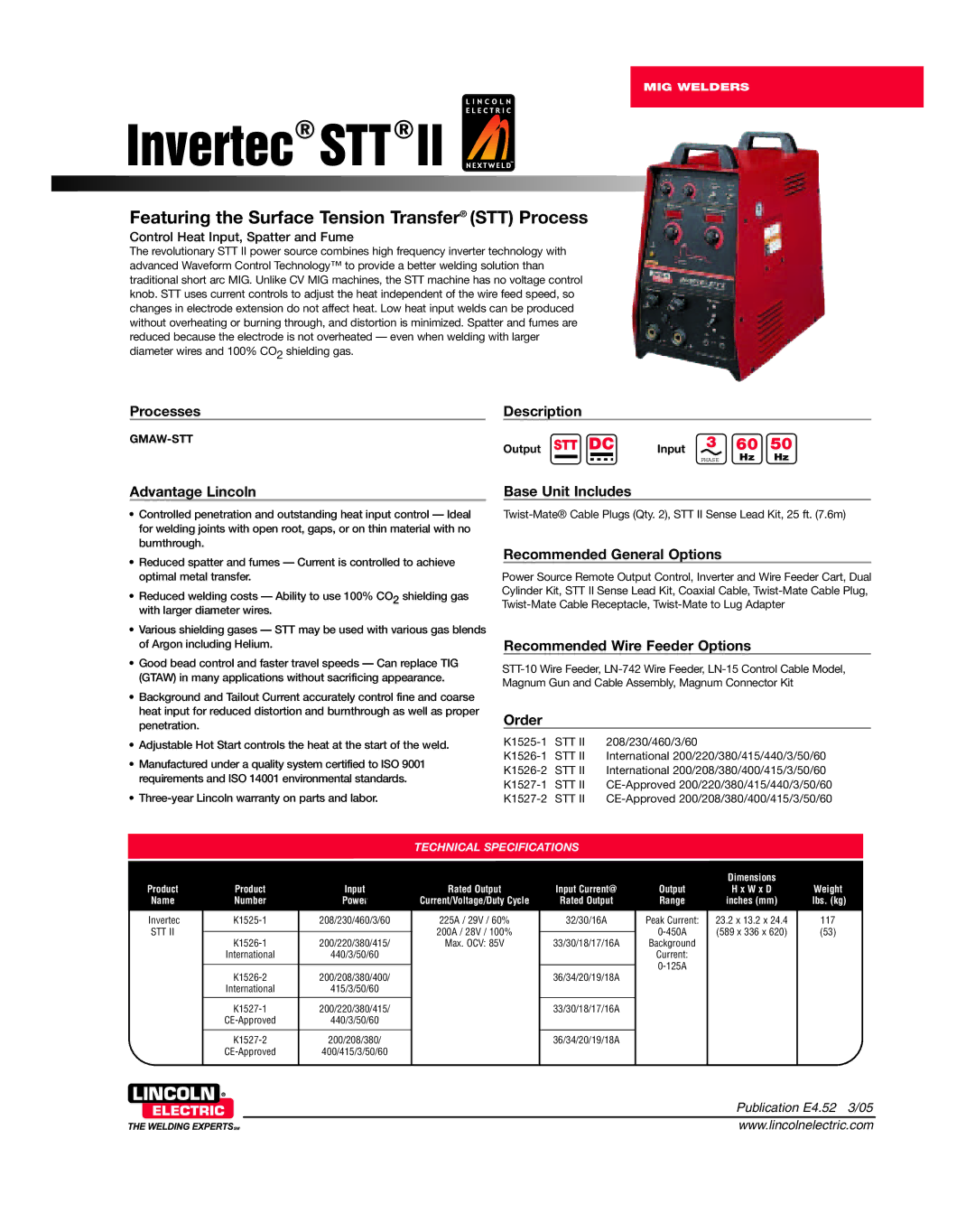

Invertec® STT®II

Featuring the Surface Tension Transfer® (STT) Process

Control Heat Input, Spatter and Fume

The revolutionary STT II power source combines high frequency inverter technology with advanced Waveform Control Technology™ to provide a better welding solution than traditional short arc MIG. Unlike CV MIG machines, the STT machine has no voltage control knob. STT uses current controls to adjust the heat independent of the wire feed speed, so changes in electrode extension do not affect heat. Low heat input welds can be produced without overheating or burning through, and distortion is minimized. Spatter and fumes are reduced because the electrode is not overheated — even when welding with larger diameter wires and 100% CO2 shielding gas.

Processes

GMAW-STT

Advantage Lincoln

•Controlled penetration and outstanding heat input control — Ideal for welding joints with open root, gaps, or on thin material with no burnthrough.

•Reduced spatter and fumes — Current is controlled to achieve optimal metal transfer.

•Reduced welding costs — Ability to use 100% CO2 shielding gas with larger diameter wires.

•Various shielding gases — STT may be used with various gas blends of Argon including Helium.

•Good bead control and faster travel speeds — Can replace TIG (GTAW) in many applications without sacrificing appearance.

•Background and Tailout Current accurately control fine and coarse heat input for reduced distortion and burnthrough as well as proper penetration.

•Adjustable Hot Start controls the heat at the start of the weld.

•Manufactured under a quality system certified to ISO 9001 requirements and ISO 14001 environmental standards.

•

Description

Output STT DC | Input 3 | 60 50 |

| PHASE | Hz Hz |

Base Unit Includes

Recommended General Options

Power Source Remote Output Control, Inverter and Wire Feeder Cart, Dual Cylinder Kit, STT II Sense Lead Kit, Coaxial Cable,

Recommended Wire Feeder Options

Order

STT II | 208/230/460/3/60 | |

STT II | International 200/220/380/415/440/3/50/60 | |

STT II | International 200/208/380/400/415/3/50/60 | |

STT II | ||

STT II |

|

Product

Name

Invertec

STT II

| Product |

| Input |

|

| Number |

| Power |

|

|

|

| ||

|

| 208/230/460/3/60 | ||

|

|

| ||

| 200/220/380/415/ | |||

| International | 440/3/50/60 | ||

|

|

| ||

| 200/208/380/400/ | |||

| International | 415/3/50/60 | ||

|

|

| ||

| 200/220/380/415/ | |||

| 440/3/50/60 | |||

|

|

| ||

| 200/208/380/ | |||

| 400/415/3/50/60 | |||

|

|

|

|

|

TECHNICAL SPECIFICATIONS

Rated Output | Input Current@ |

Current/Voltage/Duty Cycle | Rated Output |

225A / 29V / 60% | 32/30/16A |

200A / 28V / 100% |

|

| |

Max. OCV: 85V | 33/30/18/17/16A |

|

|

| 36/34/20/19/18A |

|

|

| 33/30/18/17/16A |

|

|

| 36/34/20/19/18A |

|

|

Output

Range

Peak Current:

Background

Current:

Dimensions

H x W x D

inches (mm)

23.2x 13.2 x 24.4

(589 x 336 x 620)

Weight lbs. (kg)

117

(53)

Publication E4.52 3/05

www.lincolnelectric.com