A CLOSER LOOK

USING STT FOR OPEN ROOT WELDING

Open root welding is used for pipe and

Advantages of STT Open Root

Penetration Control

•Provides reliable root pass and complete back bead. Ensures excellent sidewall fusion.

Cost Reduction

• Uses 100% CO2, the lowest cost gas, when welding carbon steel.

Flexibility

•Provides the capability of welding stainless steel, nickel alloys, and mild or high strength steels without compromising weld quality.

•Capable of welding out of position.

Low Heat Input

• Reduces burnthrough and distortion.

Low Hydrogen Weld Metal Deposit

Speed

• High quality open root welds at faster travel speeds than GTAW.

Current Control Independent of Wire Feed Speed

• Allows operator to control the heat input to the weld puddle.

Ease of Operator Use

•More forgiving process than conventional short arc welding with CV machines.

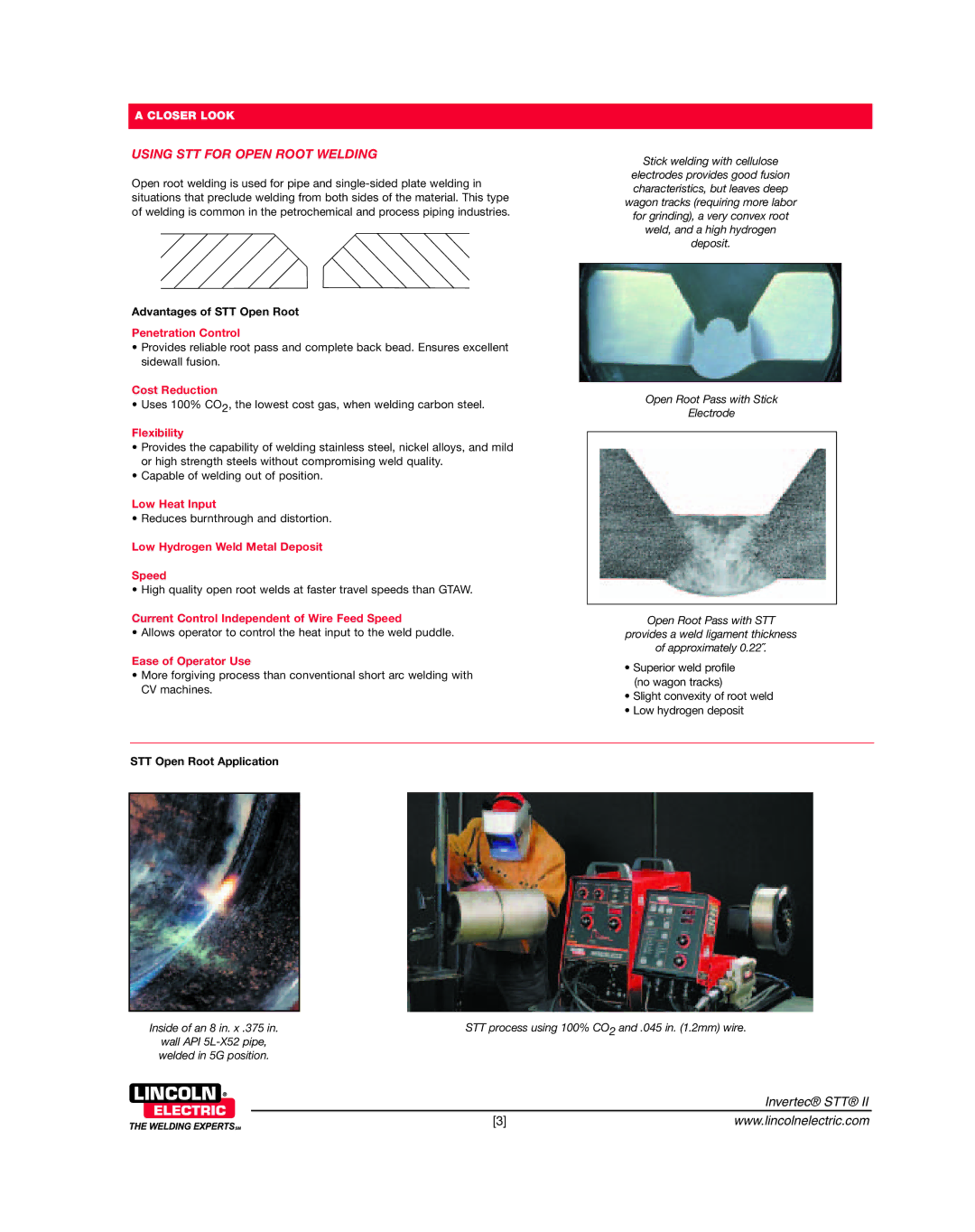

Stick welding with cellulose

electrodes provides good fusion characteristics, but leaves deep wagon tracks (requiring more labor for grinding), a very convex root weld, and a high hydrogen deposit.

Open Root Pass with Stick

Electrode

Open Root Pass with STT

provides a weld ligament thickness

of approximately 0.22˝.

•Superior weld profile (no wagon tracks)

•Slight convexity of root weld

•Low hydrogen deposit

STT Open Root Application

Inside of an 8 in. x .375 in. | STT process using 100% CO2 and .045 in. (1.2mm) wire. |

wall API |

|

welded in 5G position. |

|

| Invertec® STT® II |

[3] | www.lincolnelectric.com |