Ranger TM300 D and 300 DLX

Safety Depends on You

California Proposition 65 Warnings

Safety

Electric Shock can kill

Welding Sparks can cause fire or explosion

Précautions DE Sûreté

Ranger 300 D and 300 DLX

Master Table of Contents for ALL Sections

Table of Contents Installation Section

Technical Specifications Ranger 300 D and 300 DLX

Installation

Stacking

Safety Precautions

Location and Ventilation

Storing

PRE-OPERATION Engine Service

Engine Coolant

Battery Connections

Gases from Battery can explode

Fuel

Electrical Connections

Remote Control

High Frequency Generators for TIG Applications

Welding Terminals

Total Combined Length of Electrode and Work Cables

Auxiliary Power RECEPTACLES, PLUGS, and HAND-HELD Equipment

Welding Cable Connections

Table A.1

Premises Wiring

Figure A.2 Connection of Ranger 300 to Premises Wiring

Ranger 300 D and 300 DLX

Table of Contents Operation Section

Operation

Safety Instructions

Operating Instructions

General Description

Design Features ALL Models

For Auxiliary Power

Other Features

Ranger 300 D K1522-1

Additional Features

WELDER/GENERATOR Controls

Controls and Settings

Operation

Figure B.2 Engine Controls

Engine Controls

Operation

Before Starting the Engine

Engine Operation

Stopping the Engine

Cold Weather Starting and Operation

BREAK-IN Period

Welding Operation

Welding

AC/DC TIG Constant Current

Pure EWP Range Appropriate Tungsten Diameter Switch Settings

DC Wire Feed Welding CV with Ranger 300 DLX

Electrode Wire Speed Approximate

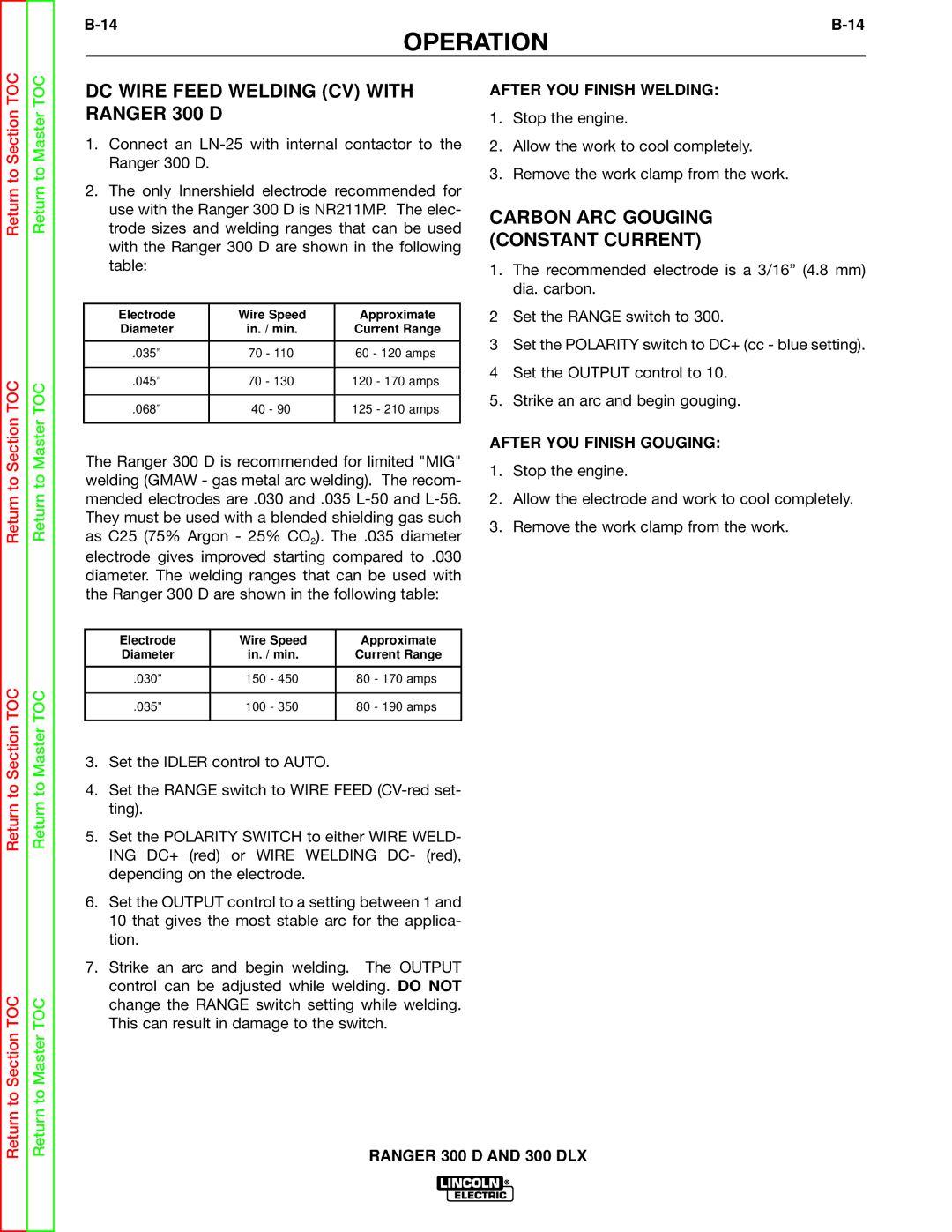

DC Wire Feed Welding CV with Ranger 300 D

Summary of Welding Processes and Machine Settings

Summary of Welding Processes and Machine Settings

Simultaneous Welding and Power Loads

Auxiliary Power

Duplex Receptacles

120/240 V Dual Voltage Receptacle

Table of Contents Accessories

TIG Welding Options Accessories

General Options Accessories

ING Terminals Always on

Connection of Lincoln Electric Wire Feeders

PIN

Remotely Controlled

ING Terminals Remotely Controlled

To Work

Return

Ranger 300 D and 300 DLX

Ranger 300 D and 300 DLX

Table of Contents Maintenance

Frequency

Safety Precautions Kubota Engine Maintenance Schedule

Engine Maintenance

Maintenance

Routine and Periodic

Fuel Feedfuel Feedpumppumplever

To prevent Electrical Damage when

Battery Maintenance

Charging the Battery

Welder / Generator Maintenance

Figure D.3 Major Component Locations

Ranger 300 D and 300 DLX

Table of Contents Theory of Operation Section

PROTECTION, ROTOR, Stator

BATTERY, STARTER, Engine

Theory of Operation

Glow PLUGS, Engine

Rotor Field FEEDBACK, Auxiliary and Wire Feeder Power

Figure E-4 Weld WINDING, Reactor and Range Switch

Weld WINDING, Reactor and Range Switch

Return to

Ranger 300 D and 300 DLX

Table of Contents Troubleshooting & Repair Section

HOW to USE Troubleshooting Guide

Troubleshooting & Repair

PC Board Troubleshooting Procedures

Output Problems

Troubleshooting Guide

On page F-6

Output Problems

Field Winding Voltage Test

Troubleshooting Guide

No DC welding output. AC welding Make sure the polarity mode

Troubleshooting & Repair

Volts is normal. If 12VDC is

Engine Problems

Symptoms Misadjustments Course of Action

Problems Possible Areas

High Speed Solenoid Resistance Test

Perform the Fuel Shutdown

Shutdown Solenoid Resis

Function Problems

Perform the Auxiliary

12VDC is

Nections at the battery

Battery does not stay charged Check for loose or faulty con

Engine charging system

Welding Problems

Test Description

Rotor Resistance Test

Materials Needed

Rotor Resistance Test

Test Procedure

Conduct the test with the engine OFF

Output Rectifier Bridge Test

Conduct this test with the engine off

Output Rectifier Bridge Test

Fuel Shutdown Solenoid Resistance Test

Figure F.3 Plug J12 Location

Fuel Shutdown Solenoid Resistance Test

High Speed Solenoid Test

High Speed Solenoid Test

Engine Throttle Adjustment Test

Conduct this procedure with the engine OFF

Engine Throttle Adjustment Test

Figure F.7 High Idle Adjustment

Oscilloscope Method

Frequency Counter Method

Auxiliary and Field Winding Test

To test the 115 VAC winding

Auxiliary and Field Winding Test

To test the 230 VAC winding

To test the field winding

To test the feeder winding Ranger 300 DLX Models

Figure F.11 14-PIN Amphenol PIN Assignments

Rotor Voltage Test

Rotor Voltage Test

Test Procedure

Charging Circuit Test

Charging Circuit Test

Alternator Test Procedure

Normal Open Circuit Voltage Waveform 115VAC Supply

Scope Settings

High Idle no Load Output Control AT Maximum

Machine Loaded

Typical DC Weld Output Voltage Waveform CV Mode High TAP

Machine Loaded to 250 Amps AT 30VDC

Machine Loaded to 250 Amps AT 25 VDC

Typical DC Weld Output Voltage Waveform

Machine Loaded to 250 Amps AT 25VDC

Typical AC Weld Output Voltage Waveform

Abnormal Open Circuit DC Weld Voltage Waveform

Abnormal Open Circuit Weld Voltage Waveform High CV Mode

Normal Open Circuit Weld Voltage Waveform High CV Mode

Normal Open Circuit DC Weld Voltage Waveform

Normal Open Circuit AC Weld Voltage Waveform

Description

Brush Removal and Replacement

Procedure

Brush Removal and Replacement

Section TOC

Field Capacitor AND/OR Rectifier Bridge Removal Replacement

Field Capacitor AND/OR Rectifier Bridge Removal

Replacement

To Section TOC

Control Board Removal and Replacement

Figure F.16 Printed Circuit Board Location

Control Board Removal and Replacement

To Section TOC

Output Rectifier Bridge Removal Replacement

Figure F.17 Output Rectifier Connections

Output Rectifier Bridge Removal and Replacement

Reassembly

Description

Ranger 300 DLX only

Output Capacitor Bank Removal and Replacement

Output Contactor Removal and Replacement Ranger 300 DLX only

Figure F.19 Output Contactor Location

Output Contactor Removal and Replacement

Troubleshooting & REPAIRs

Stator AND/OR Rotor Removal and Replacement

Figure F.21 Component LOCATIONS, STATOR/ROTOR Removal

Stator AND/OR Removal and Replacement

Stator Removal Procedure

Rotor Removal Procedure

Stator AND/OR Rotor Removal and Replacement

Lead Reconnection Checklist Engine

Reassembly Notes

Front Panel

Retest After Repair

Electrical Diagrams

R I N G D I a G R a M R a N G E R 3 0 0 D

Wiring Diagram Ranger 300 D Code

R I N G D I a G R a M R a N G E R 3 0 0 D L

Wiring Diagram Ranger 300 DLX Code

Wiring Diagram Ranger 300 DLX

Schematic Control PC Board

PC Board Assembly Control Board

Schematic Bypass PC Board

PC Board Assembly Bypass Board

SVM Error Reporting Form