INSTALLATION | ||

|

|

|

QUICK DISCONNECT PLUG (FOR STICK ELEC- TRODE CABLE)

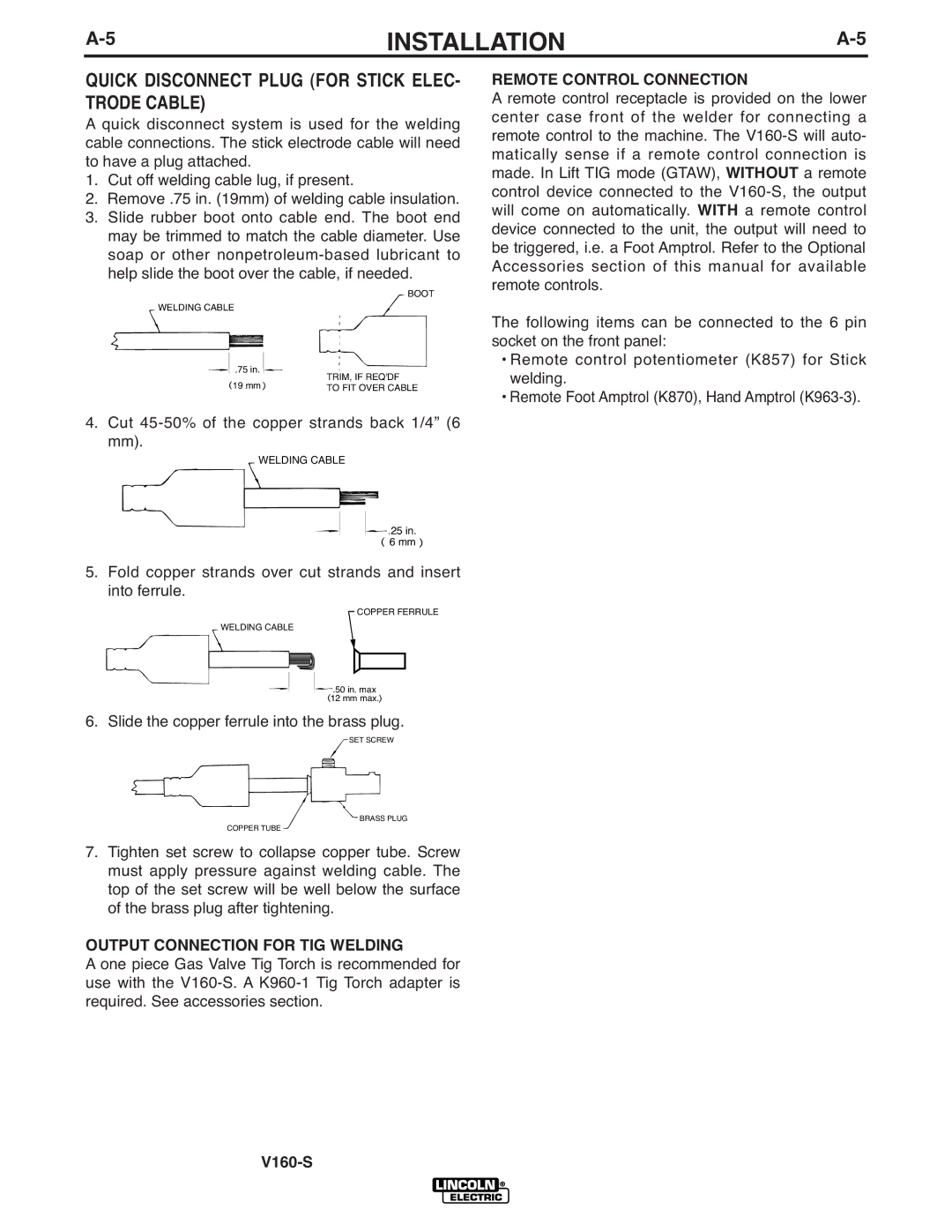

A quick disconnect system is used for the welding cable connections. The stick electrode cable will need to have a plug attached.

1.Cut off welding cable lug, if present.

2.Remove .75 in. (19mm) of welding cable insulation.

3.Slide rubber boot onto cable end. The boot end may be trimmed to match the cable diameter. Use soap or other

BOOT

WELDING CABLE

![]() .75 in.

.75 in. ![]()

19 mm | TRIM, IF REQ'D |

TO FIT OVER CABLE |

4. Cut

WELDING CABLE

![]() .25 in.

.25 in. ![]() 6 mm

6 mm ![]()

5.Fold copper strands over cut strands and insert into ferrule.

COPPER FERRULE

WELDING CABLE

![]() .50 in. max

.50 in. max ![]() 12 mm max.

12 mm max.![]()

6. Slide the copper ferrule into the brass plug.

SET SCREW

BRASS PLUG

COPPER TUBE

7.Tighten set screw to collapse copper tube. Screw must apply pressure against welding cable. The top of the set screw will be well below the surface of the brass plug after tightening.

OUTPUT CONNECTION FOR TIG WELDING

A one piece Gas Valve Tig Torch is recommended for use with the

REMOTE CONTROL CONNECTION

A remote control receptacle is provided on the lower center case front of the welder for connecting a remote control to the machine. The

The following items can be connected to the 6 pin socket on the front panel:

•Remote control potentiometer (K857) for Stick welding.

•Remote Foot Amptrol (K870), Hand Amptrol