TOOL

INSTALLATION

INSTRUCTIONS

AND USE

Selecting compressor

The air compressor must comply with the requirements of

ANSI B19.3 - 1981.

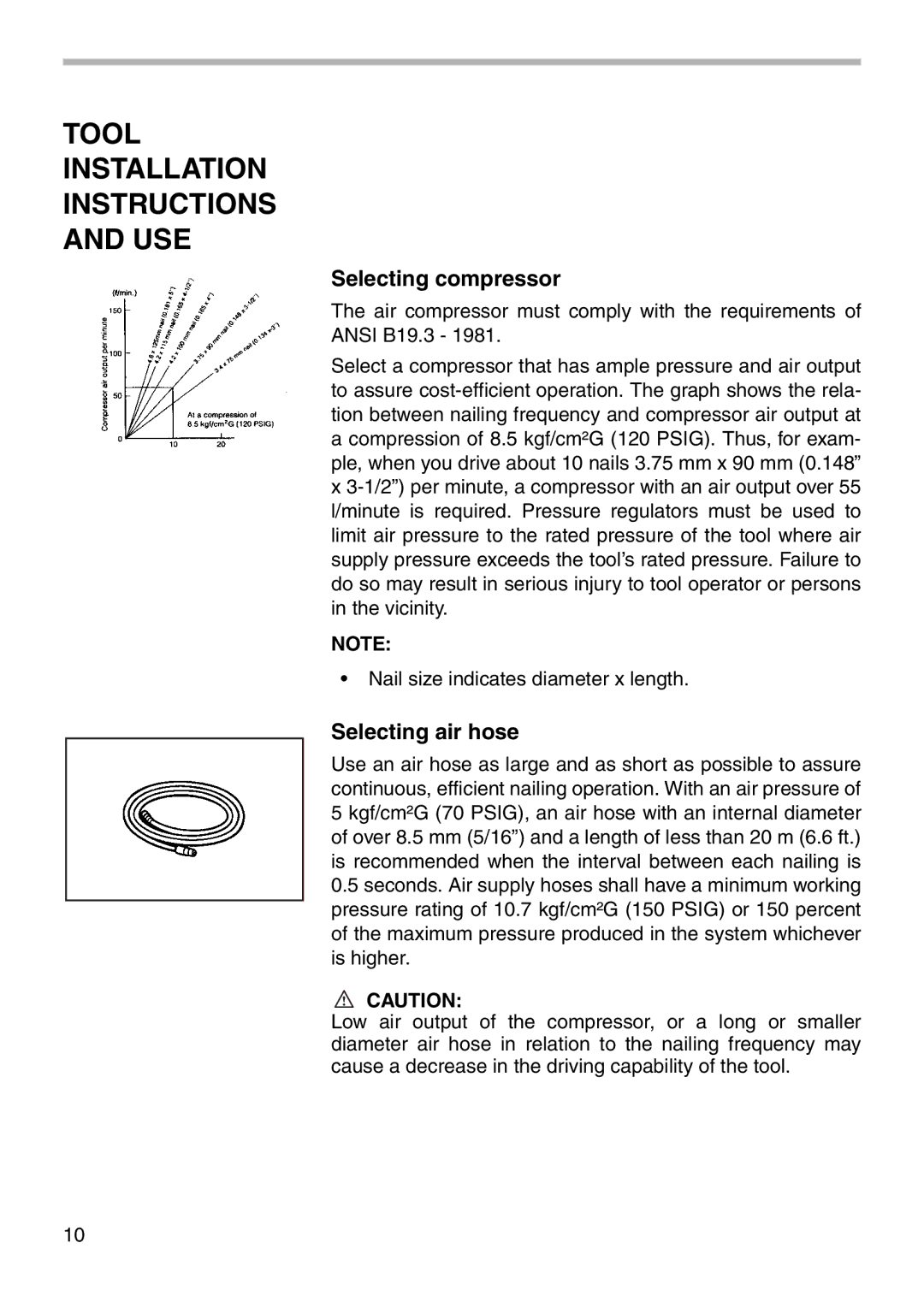

Select a compressor that has ample pressure and air output to assure

NOTE:

•Nail size indicates diameter x length.

Selecting air hose

Use an air hose as large and as short as possible to assure continuous, efficient nailing operation. With an air pressure of 5 kgf/cm²G (70 PSIG), an air hose with an internal diameter of over 8.5 mm (5/16”) and a length of less than 20 m (6.6 ft.) is recommended when the interval between each nailing is

0.5seconds. Air supply hoses shall have a minimum working pressure rating of 10.7 kgf/cm²G (150 PSIG) or 150 percent of the maximum pressure produced in the system whichever is higher.

CAUTION:

Low air output of the compressor, or a long or smaller diameter air hose in relation to the nailing frequency may cause a decrease in the driving capability of the tool.

10