Repair |

|

[3] DISASSEMBLY/ASSEMBLY |

|

| Fig. 21R |

ASSEMBLING | Correct |

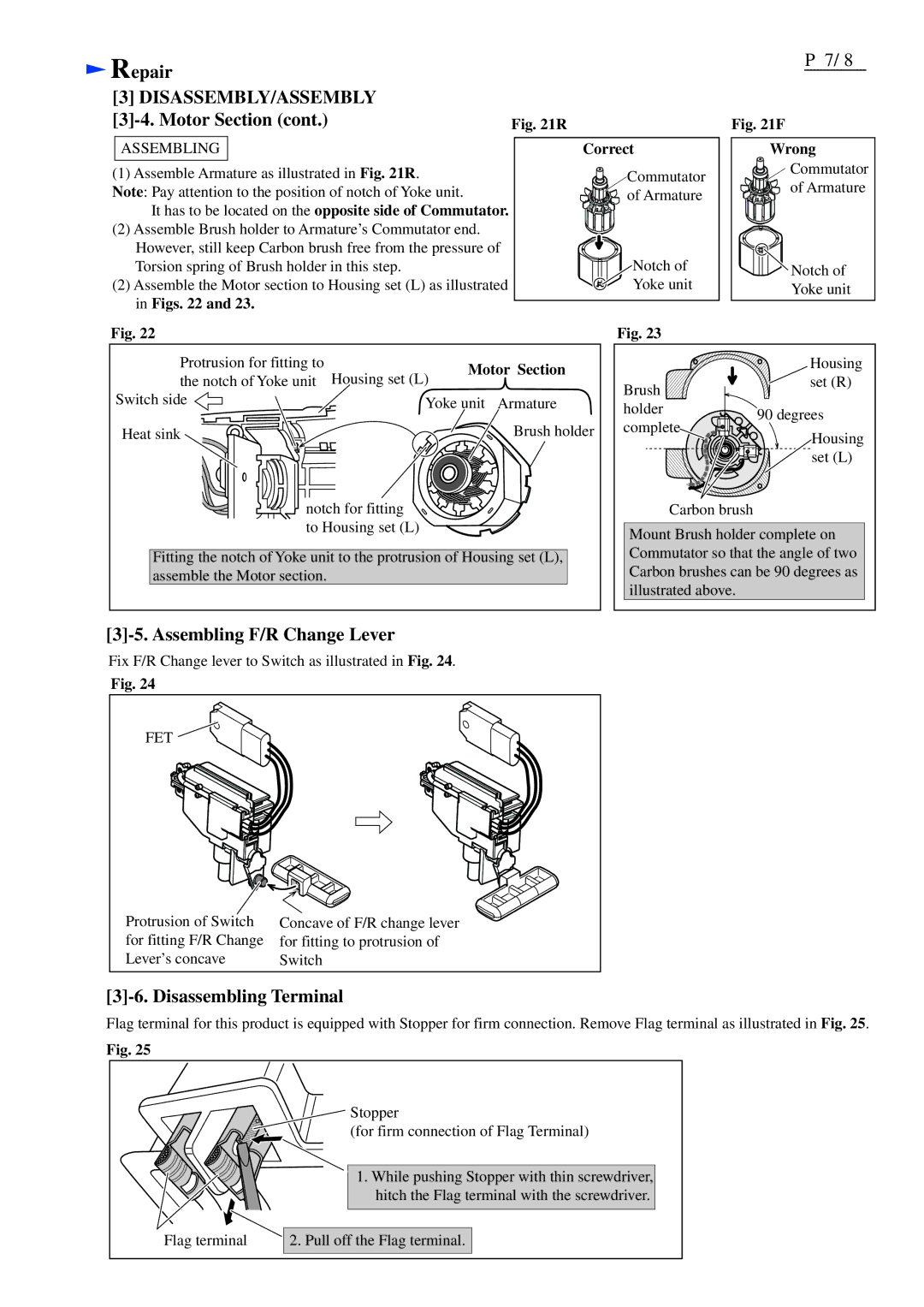

(1) Assemble Armature as illustrated in Fig. 21R. | Commutator |

Note: Pay attention to the position of notch of Yoke unit. | of Armature |

It has to be located on the opposite side of Commutator. |

|

(2) Assemble Brush holder to Armature’s Commutator end. |

|

However, still keep Carbon brush free from the pressure of |

|

Torsion spring of Brush holder in this step. | Notch of |

(2) Assemble the Motor section to Housing set (L) as illustrated | Yoke unit |

in Figs. 22 and 23. |

|

P 7/ 8

Fig. 21F

Wrong

Commutator

of Armature

![]()

![]()

![]()

![]() Notch of

Notch of

Yoke unit

Fig. 22

Protrusion for fitting to | Housing set (L) | Motor Section | |

the notch of Yoke unit | |||

| |||

Switch side | Yoke unit Armature | ||

Heat sink |

| Brush holder | |

notch for fitting |

| ||

to Housing set (L) |

| ||

Fitting the notch of Yoke unit to the protrusion of Housing set (L), assemble the Motor section.

Fig. 23

| Housing | |

Brush | set (R) | |

| ||

holder | 90 degrees | |

complete | ||

Housing | ||

| ||

| set (L) |

Carbon brush

Mount Brush holder complete on Commutator so that the angle of two Carbon brushes can be 90 degrees as illustrated above.

[3]-5. Assembling F/R Change Lever

Fix F/R Change lever to Switch as illustrated in Fig. 24.

Fig. 24

FET

Protrusion of Switch for fitting F/R Change Lever’s concave

Concave of F/R change lever for fitting to protrusion of Switch

[3]-6. Disassembling Terminal

Flag terminal for this product is equipped with Stopper for firm connection. Remove Flag terminal as illustrated in Fig. 25.

Fig. 25

Stopper

(for firm connection of Flag Terminal)

1. While pushing Stopper with thin screwdriver, hitch the Flag terminal with the screwdriver.

Flag terminal

2. Pull off the Flag terminal.