P 6/ 13

Repair

Repair

[3]DISASSEMBLY/ASSEMBLY

[3]-4. Clutch section

DISASSEMBLING

Note: When repairing Clutch section, it is recommended to entirely replace Clutch assembly with new one. However, if required to replace component parts of Clutch assembly, follow the disassembling/assembling procedure described below.

1)Take out Clutch section (=Clutch assembly) from Angle head complete. (Refer to Figs. 12 and 13)

2)Insert

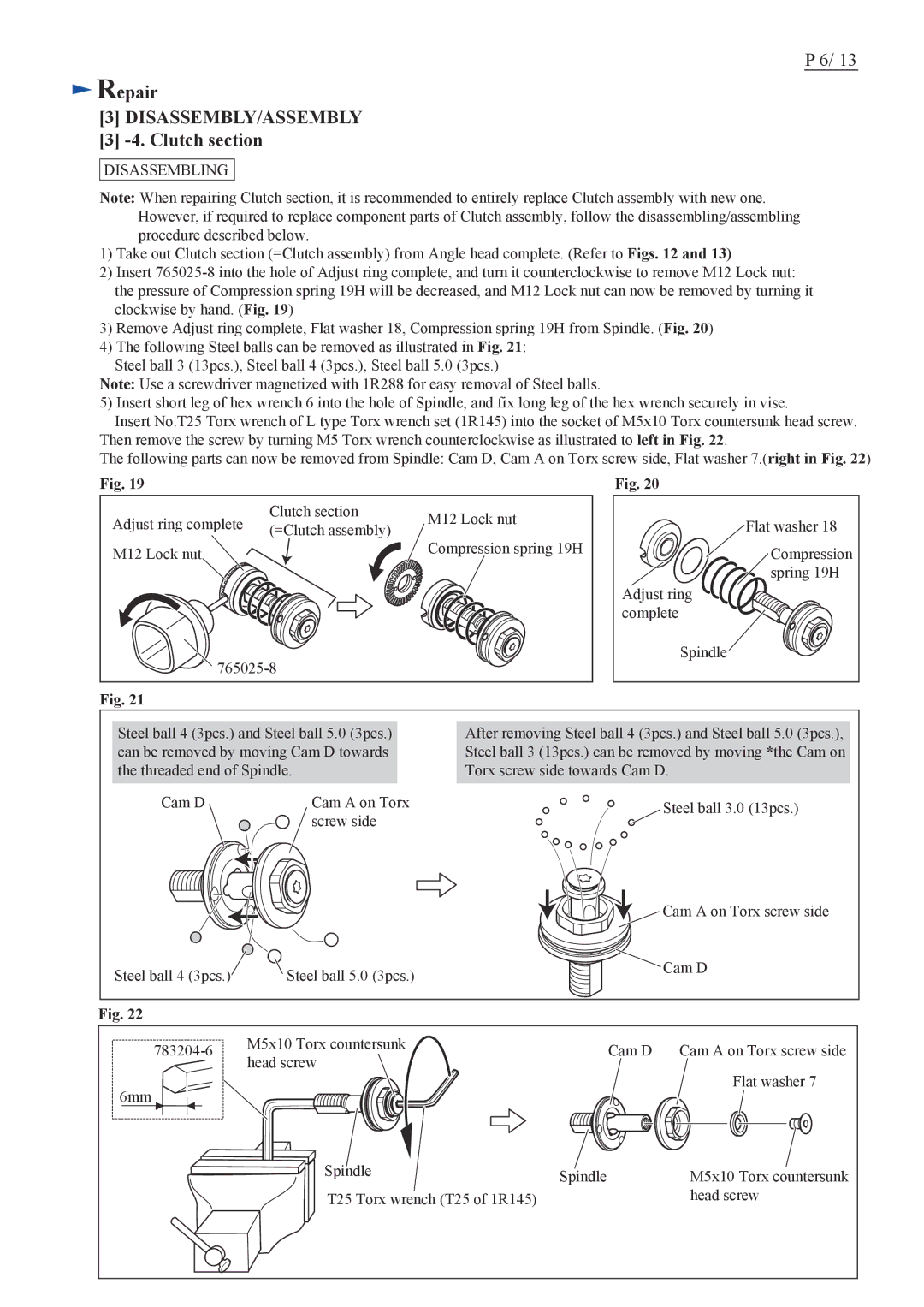

3)Remove Adjust ring complete, Flat washer 18, Compression spring 19H from Spindle. (Fig. 20)

4)The following Steel balls can be removed as illustrated in Fig. 21: Steel ball 3 (13pcs.), Steel ball 4 (3pcs.), Steel ball 5.0 (3pcs.)

Note: Use a screwdriver magnetized with 1R288 for easy removal of Steel balls.

5)Insert short leg of hex wrench 6 into the hole of Spindle, and fix long leg of the hex wrench securely in vise.

Insert No.T25 Torx wrench of L type Torx wrench set (1R145) into the socket of M5x10 Torx countersunk head screw.

Then remove the screw by turning M5 Torx wrench counterclockwise as illustrated to left in Fig. 22.

The following parts can now be removed from Spindle: Cam D, Cam A on Torx screw side, Flat washer 7.(right in Fig. 22)

Fig. 19

Adjust ring complete | Clutch section | M12 Lock nut | |

(=Clutch assembly) | |||

| |||

| Compression spring 19H | ||

M12 Lock nut |

| ||

|

|

![]()

Fig. 21

Fig. 20

Flat washer 18

Compression spring 19H

Adjust ring complete

Spindle

Steel ball 4 (3pcs.) and Steel ball 5.0 (3pcs.) can be removed by moving Cam D towards the threaded end of Spindle.

Cam D | Cam A on Torx |

| screw side |

After removing Steel ball 4 (3pcs.) and Steel ball 5.0 (3pcs.), Steel ball 3 (13pcs.) can be removed by moving *the Cam on Torx screw side towards Cam D.

Steel ball 3.0 (13pcs.)

Cam A on Torx screw side

Steel ball 4 (3pcs.) | Steel ball 5.0 (3pcs.) |

![]() Cam D

Cam D

Fig. 22

6mm |

M5x10 Torx countersunk | Cam D | Cam A on Torx screw side | |

head screw | |||

| Flat washer 7 | ||

|

|

Spindle | Spindle | M5x10 Torx countersunk |

T25 Torx wrench (T25 of 1R145) |

| head screw |