P 7/ 13

Repair

Repair

[3]DISASSEMBLY/ASSEMBLY

[3]-4. Clutch section (cont.)

ASSEMBLING

Do the reverse of the disassembling steps.

Note:

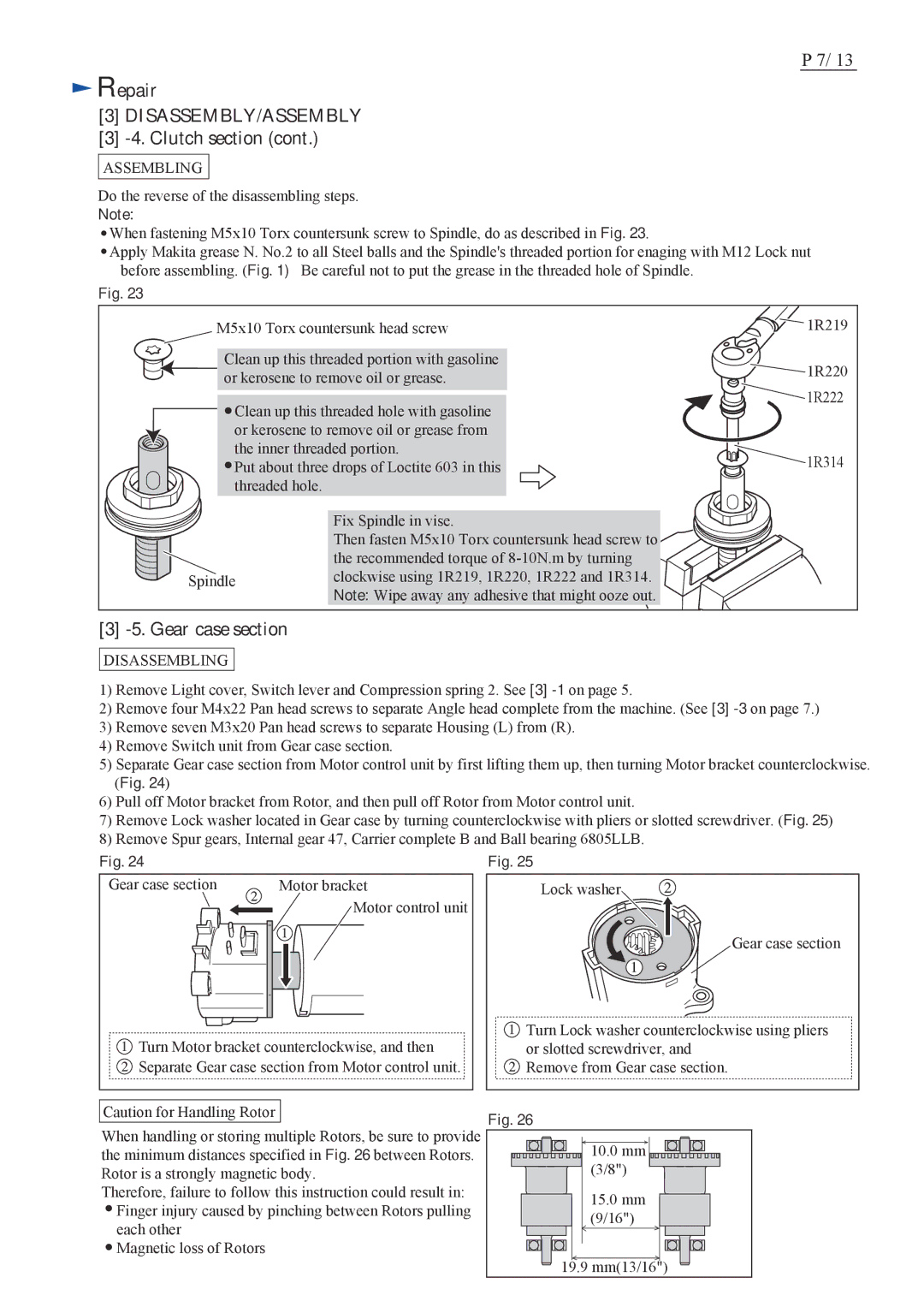

![]() When fastening M5x10 Torx countersunk screw to Spindle, do as described in Fig. 23.

When fastening M5x10 Torx countersunk screw to Spindle, do as described in Fig. 23.

![]() Apply Makita grease N. No.2 to all Steel balls and the Spindle's threaded portion for enaging with M12 Lock nut before assembling. (Fig. 1) Be careful not to put the grease in the threaded hole of Spindle.

Apply Makita grease N. No.2 to all Steel balls and the Spindle's threaded portion for enaging with M12 Lock nut before assembling. (Fig. 1) Be careful not to put the grease in the threaded hole of Spindle.

Fig. 23

M5x10 Torx countersunk head screw

![]() Clean up this threaded portion with gasoline

Clean up this threaded portion with gasoline ![]()

![]() or kerosene to remove oil or grease.

or kerosene to remove oil or grease.

![]() Clean up this threaded hole with gasoline or kerosene to remove oil or grease from the inner threaded portion.

Clean up this threaded hole with gasoline or kerosene to remove oil or grease from the inner threaded portion.

![]() Put about three drops of Loctite 603 in this threaded hole.

Put about three drops of Loctite 603 in this threaded hole.

Fix Spindle in vise.

Then fasten M5x10 Torx countersunk head screw to

the recommended torque of

Spindleclockwise using 1R219, 1R220, 1R222 and 1R314. Note: Wipe away any adhesive that might ooze out.

![]()

![]()

![]() 1R219

1R219

![]()

![]() 1R220

1R220 ![]()

![]()

![]() 1R222

1R222

![]()

![]() 1R314

1R314

[3] -5. Gear case section

DISASSEMBLING

1)Remove Light cover, Switch lever and Compression spring 2. See [3]

2)Remove four M4x22 Pan head screws to separate Angle head complete from the machine. (See [3]

3)Remove seven M3x20 Pan head screws to separate Housing (L) from (R).

4)Remove Switch unit from Gear case section.

5)Separate Gear case section from Motor control unit by first lifting them up, then turning Motor bracket counterclockwise. (Fig. 24)

6)Pull off Motor bracket from Rotor, and then pull off Rotor from Motor control unit.

7)Remove Lock washer located in Gear case by turning counterclockwise with pliers or slotted screwdriver. (Fig. 25)

8)Remove Spur gears, Internal gear 47, Carrier complete B and Ball bearing 6805LLB.

Fig. 24 |

|

Gear case section | Motor bracket |

| Motor control unit |

![]() Turn Motor bracket counterclockwise, and then

Turn Motor bracket counterclockwise, and then ![]() Separate Gear case section from Motor control unit.

Separate Gear case section from Motor control unit.

Fig. 25

Lock washer

Gear case section

![]() Turn Lock washer counterclockwise using pliers or slotted screwdriver, and

Turn Lock washer counterclockwise using pliers or slotted screwdriver, and

![]() Remove from Gear case section.

Remove from Gear case section.

Caution for Handling Rotor

When handling or storing multiple Rotors, be sure to provide the minimum distances specified in Fig. 26 between Rotors. Rotor is a strongly magnetic body.

Therefore, failure to follow this instruction could result in:

![]() Finger injury caused by pinching between Rotors pulling each other

Finger injury caused by pinching between Rotors pulling each other

![]() Magnetic loss of Rotors

Magnetic loss of Rotors

Fig. 26

10.0 mm |

(3/8") |

15.0 mm |

(9/16") |

19.9 mm(13/16") |