Importante

EM2650UH EM2650LH

Table of Contents

Symbols

Personal protective equipment

Safety Instructions

General Instructions

Intended use of the machine

Refueling

Resting Transport Refueling Maintenance Tool replacement

Kickback

Maintenance instructions

Method of operation

Cutting Tools

Never straighten or weld damaged cutting tools

When asking for help, please give the following information

First Aid

Model EM2650UH EM2650LH

Technical Data EM2650UH, EM2650LH

EM2650UH EM2650LH

Designation of Parts

For machines with bike handle models

Mounting of Handle

For machines with loop handle

Use of nylon cutting head EM2650UH, EM2650LH

Use of metal blade EM2650UH, optional accessory for EM2650LH

For EM2650UH

Mounting of Protector

For EM2650LH

Mounting of cutterblade with the hex wrench still in place

Mounting of Cutter Blade or Nylon Cutting Head

Mounting of nylon cutting head

Inspection and refill of engine oil

Point 1 in Replacement of oil Oil cap

Oil volume

Before Start of Operation

Fuel

Refueling

Handling of fuel

Storage period of fuel

Correct Handling of Machine

Points in Operation and HOW to Stop

Starting

Startup after warm-up operation

Checkup of LOW-SPEED Rotation

Adjustment of LOW-SPEED Rotation Idling

Resharpening the Cutting Tool

Stopping

100 mm

Replacing the nylon cord

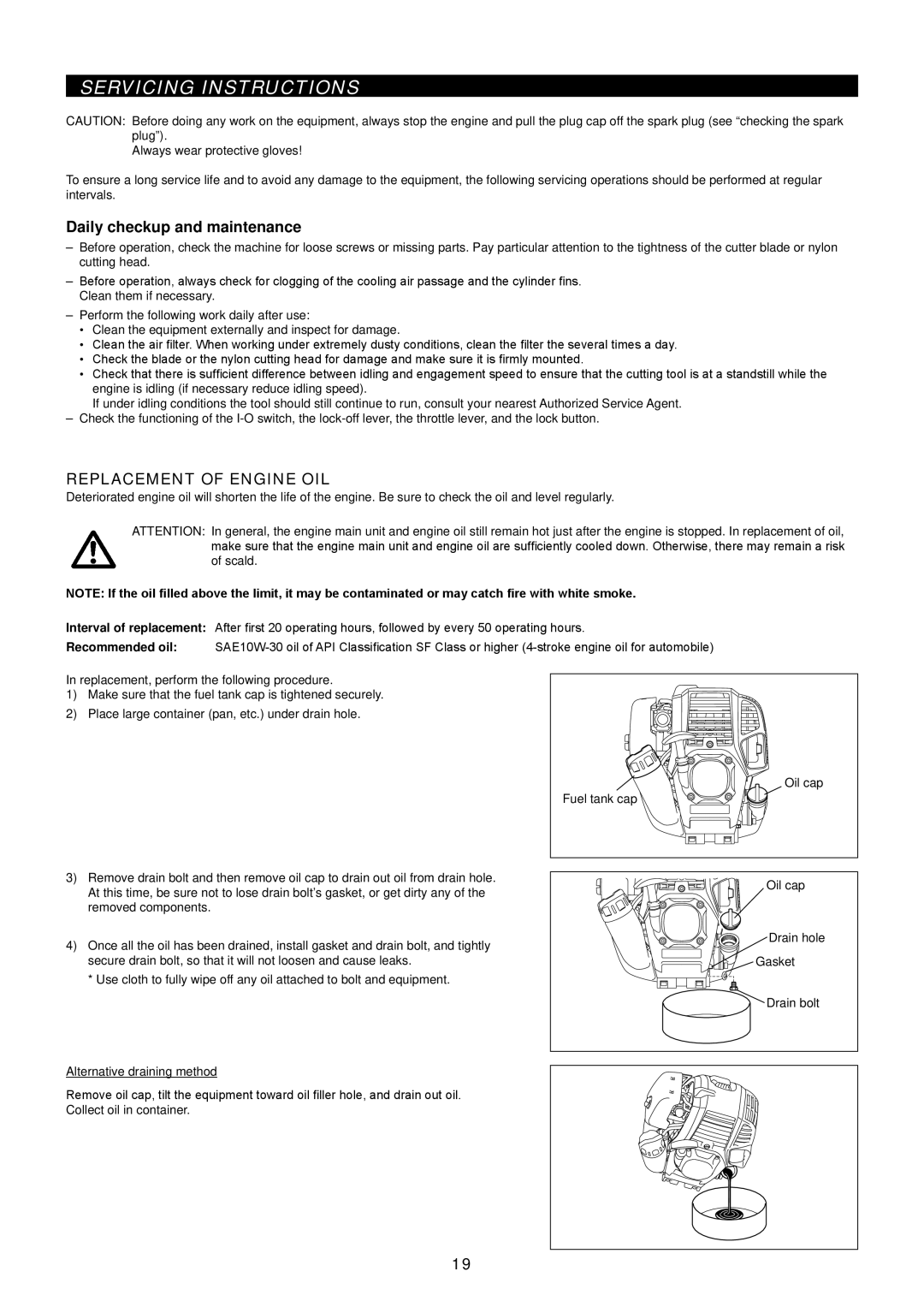

Replacement of Engine OIL

Daily checkup and maintenance

Servicing Instructions

Points in Handling Air Cleaner Element

Cleaning of AIR Cleaner

Points on OIL

Replacement of Gaskets and Packings

Cleaning of Fuel Filter

Replacement of Fuel Pipe

Cleaning of Parts

Fault System Observation Cause

Fault location

Storage

10h Rest

Operating time Before

Daily 30h 50h 200h

Operation

Blade

Troubleshooting

State of abnormality Probable cause malfunction Remedy

Starts. Once engine starts, cutter blade

Emission Compliance Period

MANUFACTURER’S Warranty Coverage

Procedure Interval

Parts Covered

Emission Component Defect Warranty Period

What is not Covered

Obtaining Warranty Service

OWNER’S Warranty Responsibilities

HOW to Make a Claim

Table des matières

Pictogrammes

Équipement de protection personnel

Consignes DE Sécurité

Consignes générales

Utilisation normale de la machine

Remplissage

Pause Transport Remplissage Entretien Remplacement d’outil

Prévention des mouvements de recul

Mode de fonctionnement

Outils de coupe

Mouvement de recul

Premiers soins

Modèle EM2650UH EM2650LH

Données Techniques EM2650UH, EM2650LH

Désignation DES Pièces

Désignation DES Pièces

Pour les machines avec guidon

Montage DE LA Poignée

Pour les machines avec poignée arceau

Poignée Sangle

Utilisation d’une tête à fils nylon EM2650UH, EM2650LH

Pour le EM2650UH

Montage DU Protecteur

Pour le EM2650LH

Makita

Montage DE LA Lame DE Coupe OU DE LA Tête À Fils Nylon

Montage de la tête à fils nylon

Inspection et remplissage de l’huile moteur

Avant Utilisation

Quantité d’huile Environ 0,08 l

Carburant

Remplissage

Manipulation de l’essence

Entreposage de l’essence

Démarrage

Manipulation Correcte DE LA Machine

Fixation de la sangle d’épaule

Détachement

Remarque

Démarrage après le réchauffage

Vérification DE LA Rotation À Faible Vitesse

Réaffûtage DE L’OUTIL DE Coupe

Arrêt

Réglage DE LA Rotation À Faible Vitesse Ralenti

Remplacement du fil nylon

Vérification et entretien quotidiens

Remplacement DE L’HUILE Moteur

Huile recommandée

Instructions D’ENTRETIEN

Nettoyage DU Filtre À AIR

Remarques Concernant L’HUILE

Lubrification DU Carter D’ENGRENAGE

Remplacement DU Tuyau D’ALIMENTATION EN Essence

Remplacement DES Joints ET Garnitures

Vérification DE LA Bougie D’ALLUMAGE

Entreposage

Emplacement des défaillances

Défaillance Système Observation Cause

Pause

Quotidien Fonctionnement

Arrêt

30 h 50 h 200 h

Lame de coupe commence. Faites très

Anomalie Cause probable dysfonctionnement Solution

Dépannage

Fois le moteur démarré, la rotation de la

ÍndicePágina

Símbolos

Equipo protector personal

Instrucciones DE Seguridad

Instrucciones generales

Uso intencionado de la herramienta

Resuministro de combustible

Prevención de retrocesos bruscos

Método de operación

Piezas cortadoras

Retrocesos bruscos

Primeros auxilios

Modelo EM2650UH EM2650LH

Especificaciones Técnicas EM2650UH, EM2650LH

Identificación DE LAS Piezas

Identificación DE LAS Piezas

Para modelos equipados con mango tipo bicicleta

Colocación DEL Mango

Para modelos equipados con mango tipo redondo

Uso de la cabeza cortadora de nailon EM2650UH, EM2650LH

Para EM2650UH

Colocación DEL Protector

Para EM2650LH

Colocación de la cabeza cortadora de nailon

Colocación DEL Disco Cortador O Cabeza Cortadora DE Nailon

Punto 1 en el reemplazo del aceite Tapa del aceite

Volumen de aceite Aprox ,08L

Antes DE Iniciar LA Operación

Inspeccione y resuministre el aceite del motor

Combustible

Reabastecimiento DE Combustible

Manejo del combustible

Periodo de almacenamiento del combustible

Puntos EN LA Operación Y Cómo Detener LA Operación

Manejo Correcto DEL Equipo

Arranque DEL Motor

Nota

Arranque tras la operación de calentamiento

Revisión DE LA Rotación DE Baja Velocidad

Reafilado DE LA Pieza Cortadora

Paro DE LA Operación

Ajuste DE LA Rotación DE Baja Velocidad Estado Pasivo

Reemplazo del cordón de nailon

Revisión y mantenimiento diarios

Instrucciones DE Servicio

Reemplazo DEL Aceite DEL Motor

Limpieza DEL Filtro DE Aire

Puntos Sobre EL Aceite

Puntos en el manejo del elemento del filtro de aire

Limpieza DE LAS Piezas

Engrasado DE LA Caja DE Cambios

Revisión DE LA Bujía DE Encendido

Inspección DE PERNOS, Tuercas Y Tornillos

Determinación de fallas

Almacenamiento

Atención

Atención tras el almacenamiento de largo plazo

30h 50h 200h

Antes Tras la Diario

Acción

Operación

Estado de anomalía Causa probable falla Solución

Resolución DE Problemas

Cortador

Periodo DE Conformidad Sobre Emisiones

Cobertura DE LA Garantía DEL Fabricante

Intervalo

Procedimiento

Piezas Cubiertas

Periodo DE Garantía POR Defectos DE Componentes DE Emisiones

LO QUE no Está Cubierto

Obtención DE Servicio DE Garantía

Responsabilidades DEL Propietario Para LA Garantía

Cómo Preparar UNA Reclamación

Page

Advertencia