Ice Machine Operation | Section 3 |

Operational Checks

GENERAL

Your Manitowoc ice machine was

To ensure proper operation, always follow these Operational Checks when starting the ice machine:

•for the first time

•after a prolonged out of service period

•after cleaning and sanitizing

Routine adjustments and maintenance procedures outlined in this manual are not covered by the warranty.

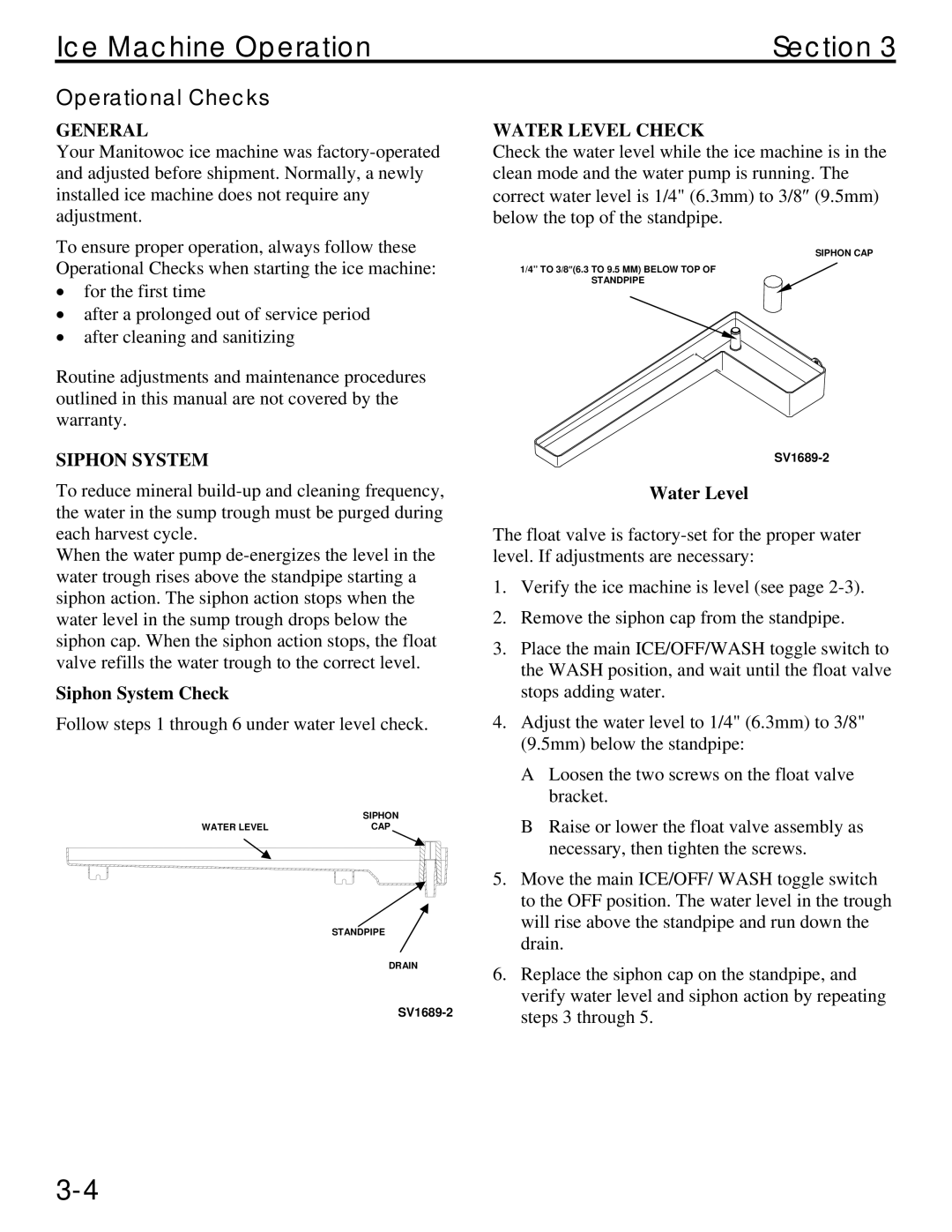

SIPHON SYSTEM

To reduce mineral

When the water pump

Siphon System Check

Follow steps 1 through 6 under water level check.

|

|

|

|

|

|

|

|

|

|

| SIPHON |

| |||||||||

|

|

|

|

|

| WATER LEVEL |

|

|

|

| CAP |

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STANDPIPE

DRAIN

WATER LEVEL CHECK

Check the water level while the ice machine is in the clean mode and the water pump is running. The correct water level is 1/4" (6.3mm) to 3/8″ (9.5mm) below the top of the standpipe.

SIPHON CAP

1/4” TO 3/8″(6.3 TO 9.5 MM) BELOW TOP OF

STANDPIPE

Water Level

The float valve is

1.Verify the ice machine is level (see page

2.Remove the siphon cap from the standpipe.

3.Place the main ICE/OFF/WASH toggle switch to the WASH position, and wait until the float valve stops adding water.

4.Adjust the water level to 1/4" (6.3mm) to 3/8" (9.5mm) below the standpipe:

A Loosen the two screws on the float valve bracket.

B Raise or lower the float valve assembly as necessary, then tighten the screws.

5.Move the main ICE/OFF/ WASH toggle switch to the OFF position. The water level in the trough will rise above the standpipe and run down the drain.

6.Replace the siphon cap on the standpipe, and verify water level and siphon action by repeating steps 3 through 5.