TROUBLE-SHOOTING

The electrical

INCOMING POWER:

Before

ELECTRIC INSPECTION:

The first step in any electrical

WARNING:

Before removing control panel or checking connec- tions and wiring, be sure that the circuit breaker for in- coming power is OFF. When power is supplied, all ex- posed terminals of the control panel carry 120 volts.

Check all wiring connections by hand to assure that both ends of all connection points are tightly secured. Use a screwdriver to tighten connection points. If nec- essary, visually inspect all

60 MINUTE TIMER:

TIMER CONTACTS:

Defective timer contacts will result in failure of either cooker compartment to operate. When this occurs, remove the control panel and proceed as follows:

1.Turn off power to the cooker at external circuit breaker.

2.Disconnect all five wires from timer terminals. (see Fig. 2, page 11).

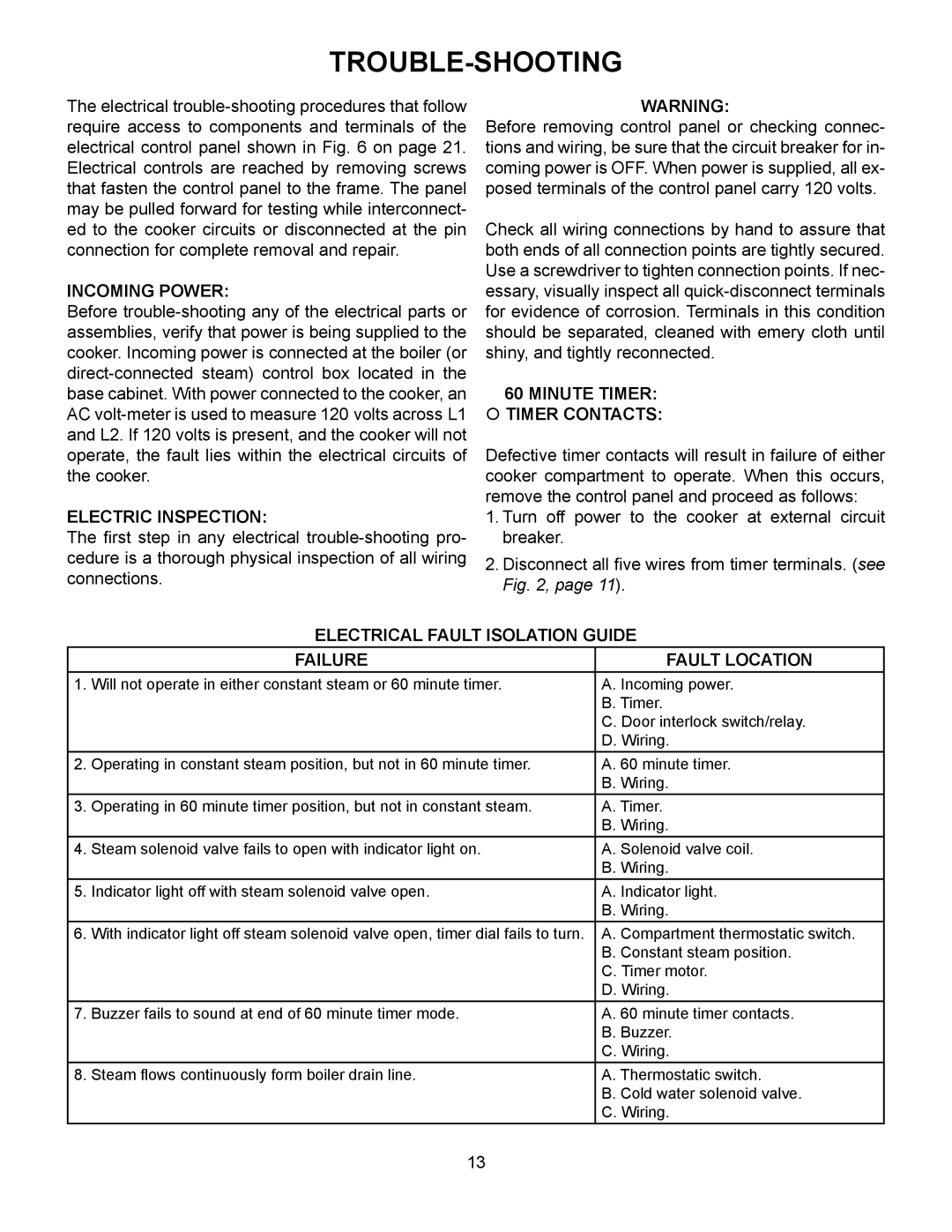

ELECTRICAL FAULT ISOLATION GUIDE

| FAILURE | FAULT LOCATION |

1. | Will not operate in either constant steam or 60 minute timer. | A. Incoming power. |

|

| B. Timer. |

|

| C. Door interlock switch/relay. |

|

| D. Wiring. |

2. | Operating in constant steam position, but not in 60 minute timer. | A. 60 minute timer. |

|

| B. Wiring. |

3. | Operating in 60 minute timer position, but not in constant steam. | A. Timer. |

|

| B. Wiring. |

4. | Steam solenoid valve fails to open with indicator light on. | A. Solenoid valve coil. |

|

| B. Wiring. |

5. | Indicator light off with steam solenoid valve open. | A. Indicator light. |

|

| B. Wiring. |

6. | With indicator light off steam solenoid valve open, timer dial fails to turn. | A. Compartment thermostatic switch. |

|

| B. Constant steam position. |

|

| C. Timer motor. |

|

| D. Wiring. |

7. | Buzzer fails to sound at end of 60 minute timer mode. | A. 60 minute timer contacts. |

|

| B. Buzzer. |

|

| C. Wiring. |

8. | Steam flows continuously form boiler drain line. | A. Thermostatic switch. |

|

| B. Cold water solenoid valve. |

|

| C. Wiring. |

13