OPERATION

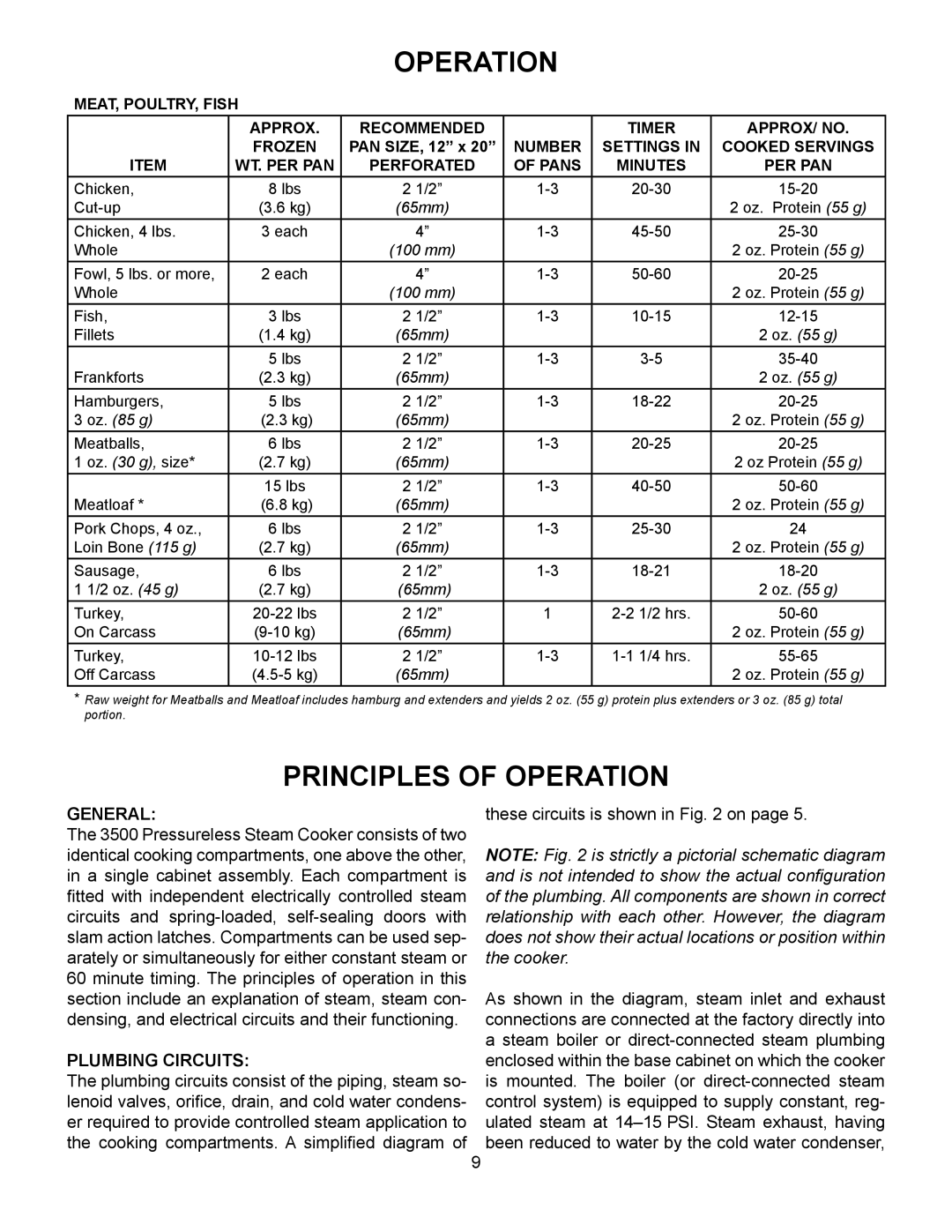

MEAT, POULTRY, FISH

| APPROX. | RECOMMENDED |

| TIMER | APPROX/ NO. | |

| FROZEN | PAN SIZE, 12” x 20” | NUMBER | SETTINGS IN | COOKED SERVINGS | |

ITEM | WT. PER PAN | PERFORATED | OF PANS | MINUTES | PER PAN | |

Chicken, | 8 lbs | 2 | 1/2” | |||

(3.6 kg) | (65mm) |

|

| 2 oz. Protein (55 g) | ||

Chicken, 4 lbs. | 3 each |

| 4” | |||

Whole |

| (100 mm) |

|

| 2 oz. Protein (55 g) | |

Fowl, 5 lbs. or more, | 2 each |

| 4” | |||

Whole |

| (100 mm) |

|

| 2 oz. Protein (55 g) | |

Fish, | 3 lbs | 2 | 1/2” | |||

Fillets | (1.4 kg) | (65mm) |

|

| 2 oz. (55 g) | |

| 5 lbs | 2 | 1/2” | |||

Frankforts | (2.3 kg) | (65mm) |

|

| 2 oz. (55 g) | |

Hamburgers, | 5 lbs | 2 | 1/2” | |||

3 oz. (85 g) | (2.3 kg) | (65mm) |

|

| 2 oz. Protein (55 g) | |

Meatballs, | 6 lbs | 2 | 1/2” | |||

1 oz. (30 g), size* | (2.7 kg) | (65mm) |

|

| 2 oz Protein (55 g) | |

| 15 lbs | 2 | 1/2” | |||

Meatloaf * | (6.8 kg) | (65mm) |

|

| 2 oz. Protein (55 g) | |

Pork Chops, 4 oz., | 6 lbs | 2 | 1/2” | 24 | ||

Loin Bone (115 g) | (2.7 kg) | (65mm) |

|

| 2 oz. Protein (55 g) | |

Sausage, | 6 lbs | 2 | 1/2” | |||

1 1/2 oz. (45 g) | (2.7 kg) | (65mm) |

|

| 2 oz. (55 g) | |

Turkey, | 2 | 1/2” | 1 | |||

On Carcass | (65mm) |

|

| 2 oz. Protein (55 g) | ||

Turkey, | 2 | 1/2” | ||||

Off Carcass | (65mm) |

|

| 2 oz. Protein (55 g) | ||

*Raw weight for Meatballs and Meatloaf includes hamburg and extenders and yields 2 oz. (55 g) protein plus extenders or 3 oz. (85 g) total portion.

PRINCIPLES OF OPERATION

GENERAL:

The 3500 Pressureless Steam Cooker consists of two identical cooking compartments, one above the other, in a single cabinet assembly. Each compartment is fitted with independent electrically controlled steam circuits and

PLUMBING CIRCUITS:

The plumbing circuits consist of the piping, steam so- lenoid valves, orifice, drain, and cold water condens- er required to provide controlled steam application to the cooking compartments. A simplified diagram of

these circuits is shown in Fig. 2 on page 5.

NOTE: Fig. 2 is strictly a pictorial schematic diagram and is not intended to show the actual configuration of the plumbing. All components are shown in correct relationship with each other. However, the diagram does not show their actual locations or position within the cooker.

As shown in the diagram, steam inlet and exhaust connections are connected at the factory directly into a steam boiler or

9