SAFE PRACTICES FOR GARDEN TILLERS

TRAINING

Regard your tiller as a piece of power equipment and teach this respect to all who operate it.

Read the owner’s manual carefully. Be thoroughly familiar with the controls and proper use of the equipment. Know how to stop the unit and disengage the controls quickly.

Never allow children to operate equipment. Never allow adults to operate equipment without proper instruction.

Keep the area of operation clear of all persons, especially small children.

Exercise caution to avoid slipping and falling.

PREPARATION

Check the tiller to make certain it is in good operating con- dition.

Check tines to be sure they are free of any obstruction. Check engine crankcase oil level.

Unless there is very good artificial light operate during day- light hours only.

Do not operate power tools in wet soil, which clogs the cutter and increases the danger of your slipping and falling and possibly coming into contact with the tines.

Thoroughly inspect the area where the equipment is to be used and remove all large stones, boards, wires, and other foreign objects.

Do not operate machine when barefoot or wearing open sandals. Wear strong

Check that clutch is disengaged before starting engine. Handle fuel with care; it is highly flammable.

•Use approved fuel container.

•Never add fuel to a running engine or hot engine.

•Fill fuel tank outdoors with extreme care. Never fill fuel tank while smoking.

•Replace gasoline cap securely and wipe up spilled fuel.

Never attempt to make any adjustments while engine is running except carburetor mixture as instructed in the en- gine owner’s guide.

Allow engine sufficient

OPERATION

Give complete and undivided attention to the job at hand.

Familiarize yourself with the controls. Be sure you know how to stop your machine quickly. Do not start engine until you set machine on ground to be tilled.

Hold the handle with your left hand while pulling the starter rope with your right. Be sure the machine will not tip or roll during the starting operation.

Stay clear of the front of

Keep in step with machine. Do not lag behind or let it pull

you so you will not be in full command of the machine. Control the direction of the machine by hand pressure on the handle, not by foot pressure on the machine housing.

Stay alert for hidden hazards.

When operating over uneven terrain and slopes, use extreme care and make sure of solid and firm footing at all times.

Exercise special care when operating around objects to prevent the tines from striking them and never deliberately operate over any object.

After striking a foreign object, stop the engine, remove wire from spark plug, thoroughly inspect the tiller for any dam- age and repair the damage before restarting and operating the tiller.

If the unit should start to vibrate abnormally, stop the engine and check immediately for the cause. Vibration is generally a warning of trouble.

Stop operation when another person approaches.

Stop the engine whenever you leave the operating position before making any repairs, adjustment, or inspections.

Stop the engine whenever leaving the tiller unattended.

When cleaning, repairing, or inspecting make certain tines and all moving parts have stopped. Disconnect spark plug wire and keep wire away from plug to prevent accidental starting.

Do not run engine indoors.

Exercise extreme caution when changing direction on slopes. Do not attempt to till steep slopes.

Never operate tiller without guards, plates, or other safety protective devices in place.

Never operate tiller near glass enclosure, automobiles, window wells,

Do not over load machine capacity by attempting to till ground at too fast a rate.

Use care when backing.

Never allow anyone in front of unit. Disengage clutch, when someone approaches, when transporting or when not in use.

Use only attachments and accessories approved by manu- facturer of tiller.

Never operate tiller without good visibility or light. Always be sure of your footing and keep a firm hold on the handles and walk, never run.

MAINTENANCE AND STORAGE

Follow the recommendations for maintenance described in this manual and engine literature.

Have a competent service man make a thorough inspection of the tiller before the season begins.

Check shear bolts and engine mounting bolts at frequent intervals for proper tightness to be sure equipment is in safe working condition. Check that the engine stop circuit is intact.

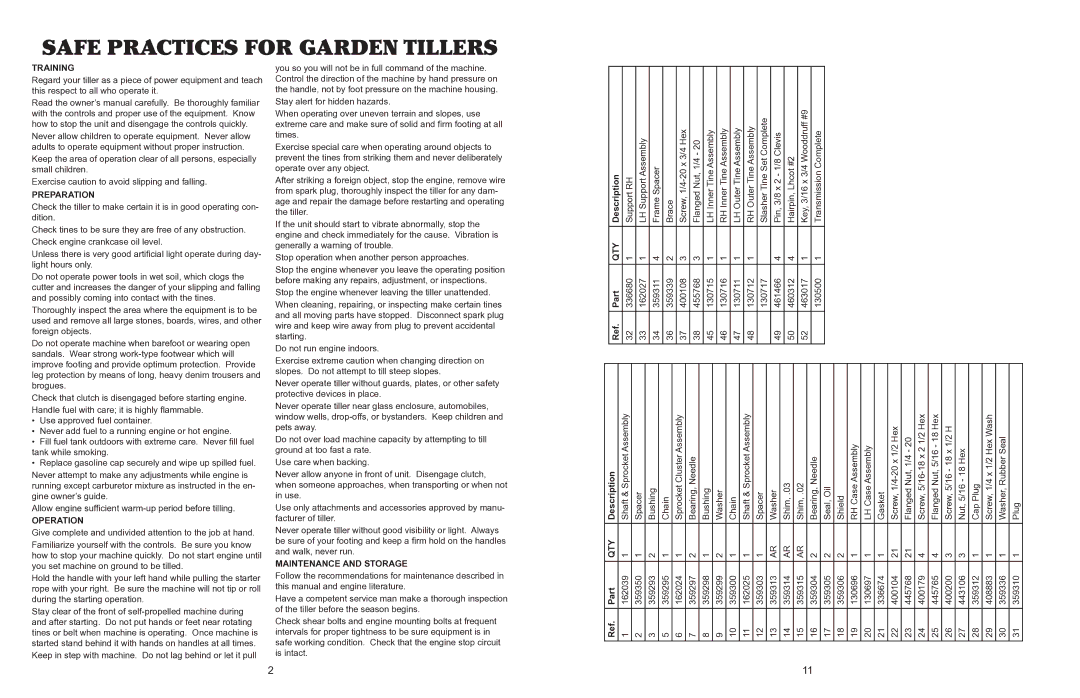

| Description |

| Support RH |

| LH Support Assembly |

| Frame Spacer |

| Brace | Screw, |

| Flanged Nut, 1/4 - 20 |

| LH Inner Tine Assembly |

| RH Inner Tine Assembly |

| LH Outer Tine Assembly |

| RH Outer Tine Assembly |

| Slasher Tine Set Complete |

| Pin, 3/8 x 2 - 1/8 Clevis |

| Hairpin, Lhcot #2 |

| Key, 3/16 x 3/4 Wooddruff #9 |

| Transmission Complete |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||

| QTY |

| 1 | 1 | 4 | 2 | 3 | 3 | 1 | 1 | 1 | 1 |

|

|

| 4 | 4 | 1 | 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| Part |

| 336680 |

| 162027 |

| 359311 |

| 359339 |

| 400108 |

| 455768 |

| 130715 |

| 130716 |

| 130711 |

| 130712 |

| 130717 |

| 461466 |

| 460312 |

| 463017 |

| 130500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| Ref. |

| 32 |

| 33 |

| 34 |

| 36 |

| 37 |

| 38 |

| 45 |

| 46 |

| 47 |

| 48 |

|

|

| 49 |

| 50 |

| 52 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Description |

| Shaft & Sprocket Assembly | Spacer | Bushing | Chain | Sprocket Cluster Assembly | Bearing, Needle | Bushing | Washer | Chain | Shaft & Sprocket Assembly | Spacer | Washer | Shim, .03 | Shim, .02 | Bearing, Needle | Seal, Oil | Shield | RH Case Assembly | LH Case Assembly | Gasket | Screw, | Flanged Nut, 1/4 - 20 | Screw, | Flanged Nut, 5/16 - 18 Hex | Screw, 5/16 - 18 x 1/2 H | Nut, 5/16 - 18 Hex | Cap Plug | Screw, 1/4 x 1/2 Hex Wash | Washer, Rubber Seal | Plug | |||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

QTY | 1 | 1 | 2 | 1 | 1 | 2 | 1 | 2 | 1 | 1 | 1 | AR | AR | AR | 2 | 2 | 2 | 1 | 1 | 1 | 21 | 21 | 4 | 4 | 3 | 3 | 1 | 1 | 1 | 1 | ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Part |

| 162039 | 359350 | 359293 | 359295 | 162024 | 359297 | 359298 | 359299 | 359300 | 162025 | 359303 | 359313 | 359314 | 359315 | 359304 | 359305 | 359306 | 130696 | 130697 | 336674 | 400104 | 445768 | 400179 | 445765 | 400200 | 443106 | 359312 | 408883 | 359336 | 359310 | |||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ref. |

| 1 | 2 | 3 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | |||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 | 11 |