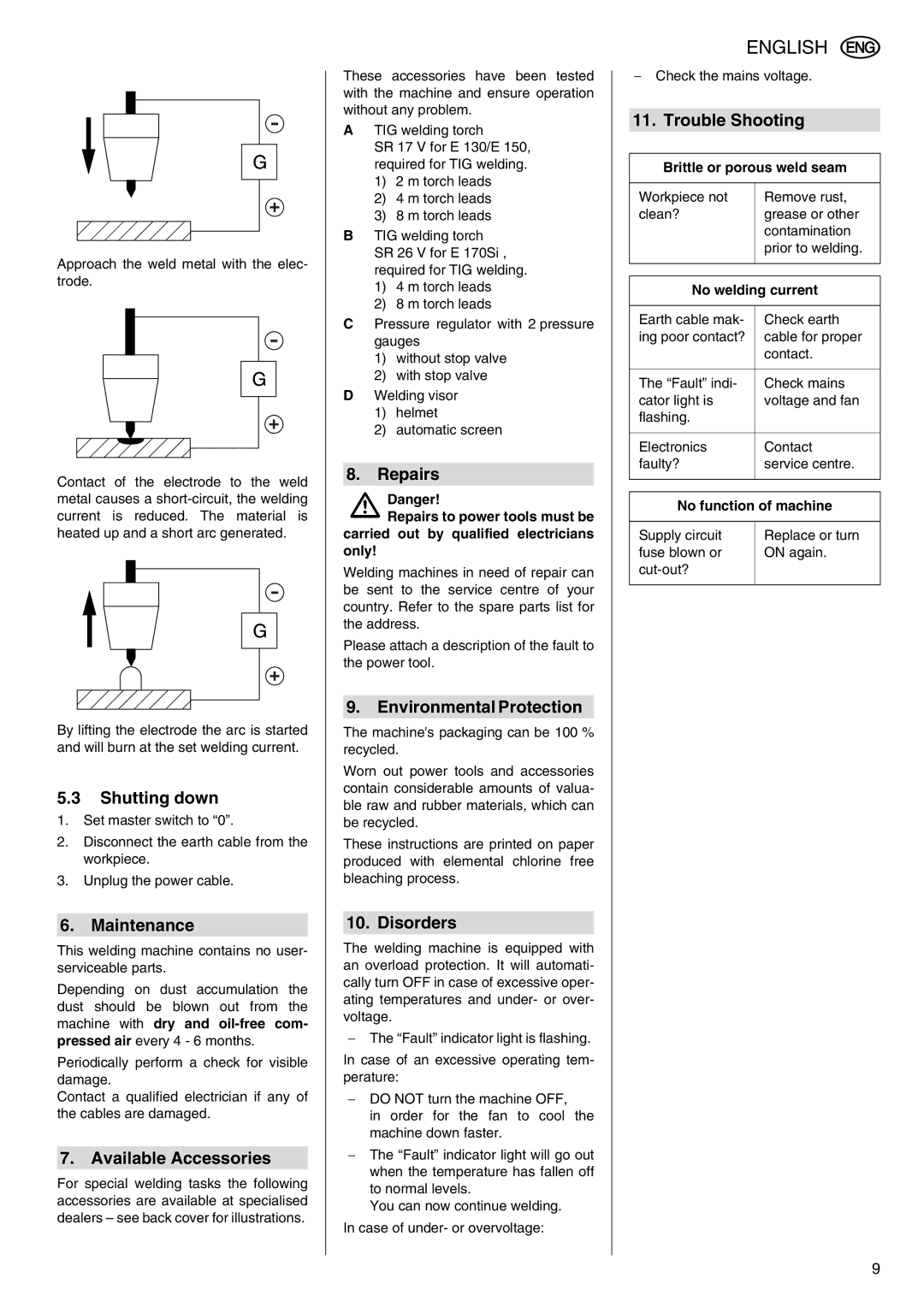

Approach the weld metal with the elec- trode.

Contact of the electrode to the weld metal causes a

By lifting the electrode the arc is started and will burn at the set welding current.

5.3Shutting down

1.Set master switch to “0”.

2.Disconnect the earth cable from the workpiece.

3.Unplug the power cable.

6.Maintenance

This welding machine contains no user- serviceable parts.

Depending on dust accumulation the dust should be blown out from the machine with dry and

Periodically perform a check for visible damage.

Contact a qualified electrician if any of the cables are damaged.

7. Available Accessories

For special welding tasks the following accessories are available at specialised dealers – see back cover for illustrations.

These accessories have been tested with the machine and ensure operation without any problem.

ATIG welding torch

SR 17 V for E 130/E 150, required for TIG welding.

1)2 m torch leads

2)4 m torch leads

3)8 m torch leads

BTIG welding torch SR 26 V for E 170Si , required for TIG welding.

1)4 m torch leads

2)8 m torch leads

CPressure regulator with 2 pressure gauges

1)without stop valve

2)with stop valve

DWelding visor

1)helmet

2)automatic screen

8.Repairs

ADanger!Repairs to power tools must be carried out by qualified electricians only!

Welding machines in need of repair can be sent to the service centre of your country. Refer to the spare parts list for the address.

Please attach a description of the fault to the power tool.

9. Environmental Protection

The machine's packaging can be 100 % recycled.

Worn out power tools and accessories contain considerable amounts of valua- ble raw and rubber materials, which can be recycled.

These instructions are printed on paper produced with elemental chlorine free bleaching process.

10. Disorders

The welding machine is equipped with an overload protection. It will automati- cally turn OFF in case of excessive oper- ating temperatures and under- or over- voltage.

−The “Fault” indicator light is flashing.

In case of an excessive operating tem- perature:

−DO NOT turn the machine OFF,

in order for the fan to cool the machine down faster.

−The “Fault” indicator light will go out when the temperature has fallen off to normal levels.

You can now continue welding.

In case of under- or overvoltage:

ENGLISH

−Check the mains voltage.

11. Trouble Shooting

Brittle or porous weld seam

Workpiece not | Remove rust, |

clean? | grease or other |

| contamination |

| prior to welding. |

|

|

| |

No welding current | |

|

|

Earth cable mak- | Check earth |

ing poor contact? | cable for proper |

| contact. |

|

|

The “Fault” indi- | Check mains |

cator light is | voltage and fan |

flashing. |

|

|

|

Electronics | Contact |

faulty? | service centre. |

|

|

| |

No function of machine | |

|

|

Supply circuit | Replace or turn |

fuse blown or | ON again. |

| |

|

|

9