Trouble | Remedy |

|

|

Information on display board is not accu- | Have Factory Authorized Service Agent check Control board PC1. |

rate. |

|

|

|

| Check transducer HD1 and connections, and replace if necessary. |

|

|

Display on display board does not light. | Have Factory Authorized Service Agent check Control board PC1. |

|

|

| Replace display board. |

|

|

Segments on the display board are | Replace display board. |

missing. |

|

|

|

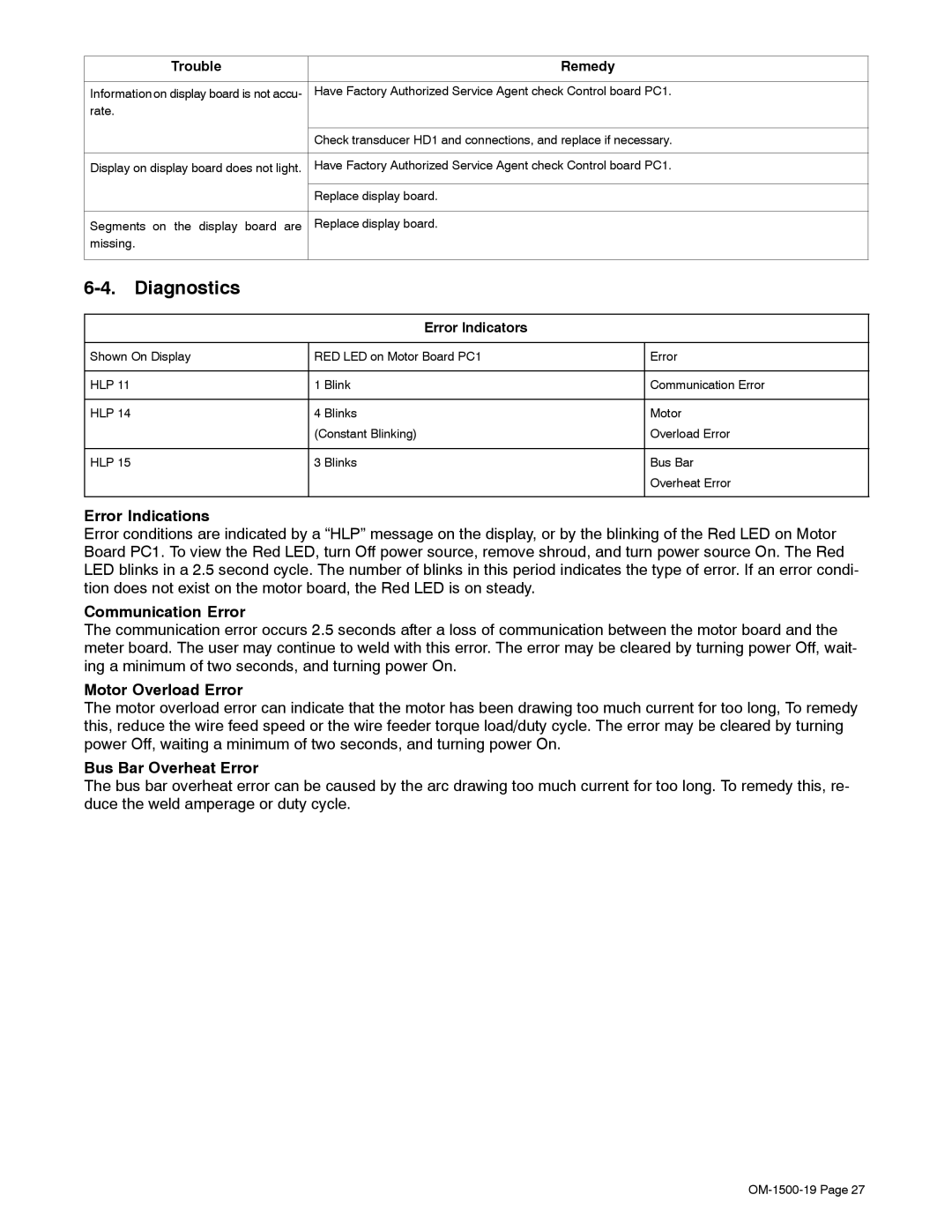

6-4. Diagnostics

Error Indicators

Shown On Display | RED LED on Motor Board PC1 | Error | |

|

|

|

|

HLP 11 | 1 | Blink | Communication Error |

|

|

|

|

HLP 14 | 4 | Blinks | Motor |

| (Constant Blinking) | Overload Error | |

|

|

|

|

HLP 15 | 3 | Blinks | Bus Bar |

|

|

| Overheat Error |

|

|

|

|

Error Indications

Error conditions are indicated by a “HLP” message on the display, or by the blinking of the Red LED on Motor Board PC1. To view the Red LED, turn Off power source, remove shroud, and turn power source On. The Red LED blinks in a 2.5 second cycle. The number of blinks in this period indicates the type of error. If an error condi- tion does not exist on the motor board, the Red LED is on steady.

Communication Error

The communication error occurs 2.5 seconds after a loss of communication between the motor board and the meter board. The user may continue to weld with this error. The error may be cleared by turning power Off, wait- ing a minimum of two seconds, and turning power On.

Motor Overload Error

The motor overload error can indicate that the motor has been drawing too much current for too long, To remedy this, reduce the wire feed speed or the wire feeder torque load/duty cycle. The error may be cleared by turning power Off, waiting a minimum of two seconds, and turning power On.

Bus Bar Overheat Error

The bus bar overheat error can be caused by the arc drawing too much current for too long. To remedy this, re- duce the weld amperage or duty cycle.