SECTION 5 − OPERATION

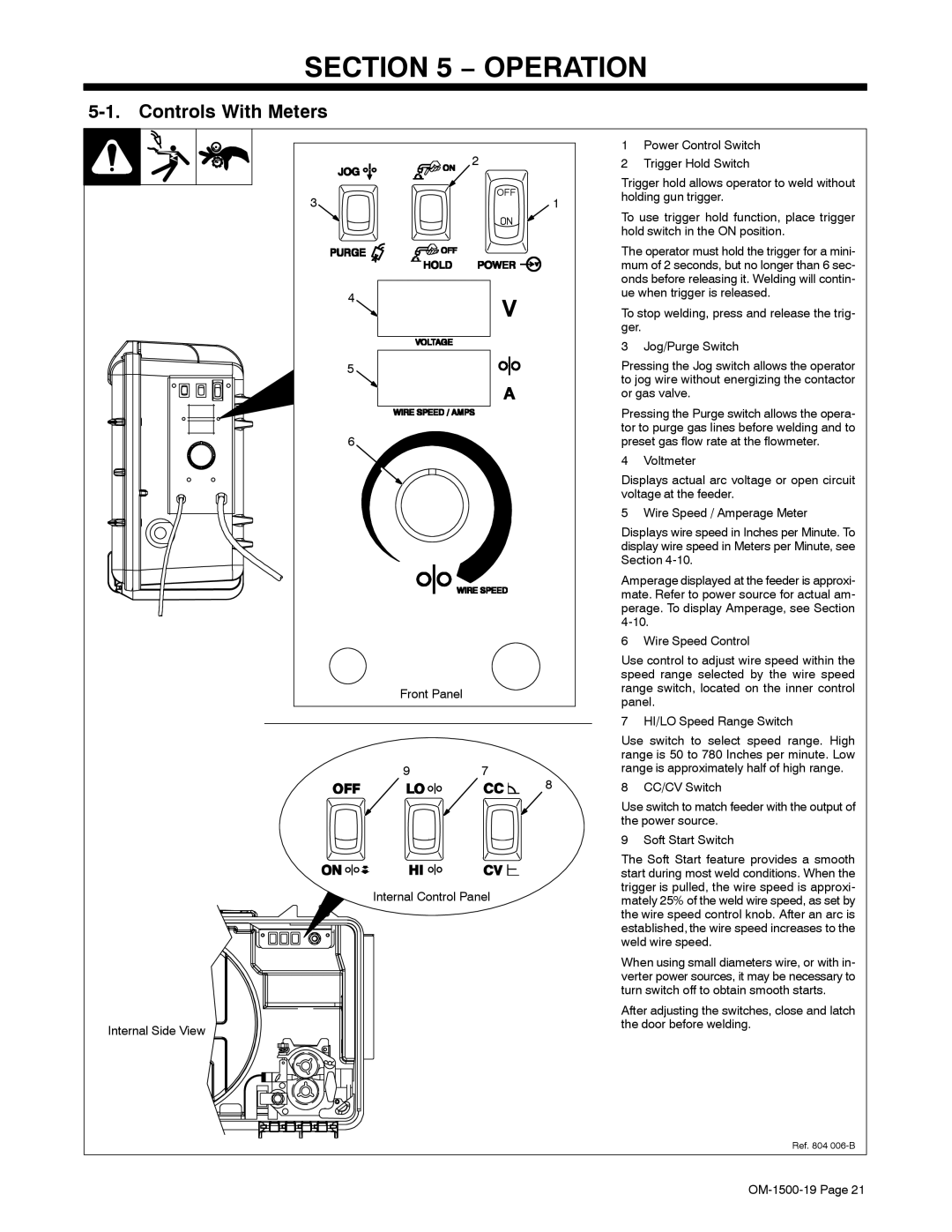

5-1. Controls With Meters

| 2 |

3 | OFF |

1 |

4

5

6

Front Panel

97 ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() 8

8

Internal Control Panel

Internal Side View

1Power Control Switch

2Trigger Hold Switch

Trigger hold allows operator to weld without holding gun trigger.

To use trigger hold function, place trigger hold switch in the ON position.

The operator must hold the trigger for a mini- mum of 2 seconds, but no longer than 6 sec- onds before releasing it. Welding will contin- ue when trigger is released.

To stop welding, press and release the trig- ger.

3 Jog/Purge Switch

Pressing the Jog switch allows the operator to jog wire without energizing the contactor or gas valve.

Pressing the Purge switch allows the opera- tor to purge gas lines before welding and to preset gas flow rate at the flowmeter.

4 Voltmeter

Displays actual arc voltage or open circuit voltage at the feeder.

5 Wire Speed / Amperage Meter

Displays wire speed in Inches per Minute. To display wire speed in Meters per Minute, see Section

Amperage displayed at the feeder is approxi- mate. Refer to power source for actual am- perage. To display Amperage, see Section

6 Wire Speed Control

Use control to adjust wire speed within the speed range selected by the wire speed range switch, located on the inner control panel.

7 HI/LO Speed Range Switch

Use switch to select speed range. High range is 50 to 780 Inches per minute. Low range is approximately half of high range.

8 CC/CV Switch

Use switch to match feeder with the output of the power source.

9 Soft Start Switch

The Soft Start feature provides a smooth start during most weld conditions. When the trigger is pulled, the wire speed is approxi- mately 25% of the weld wire speed, as set by the wire speed control knob. After an arc is established, the wire speed increases to the weld wire speed.

When using small diameters wire, or with in- verter power sources, it may be necessary to turn switch off to obtain smooth starts.

After adjusting the switches, close and latch the door before welding.

Ref. 804