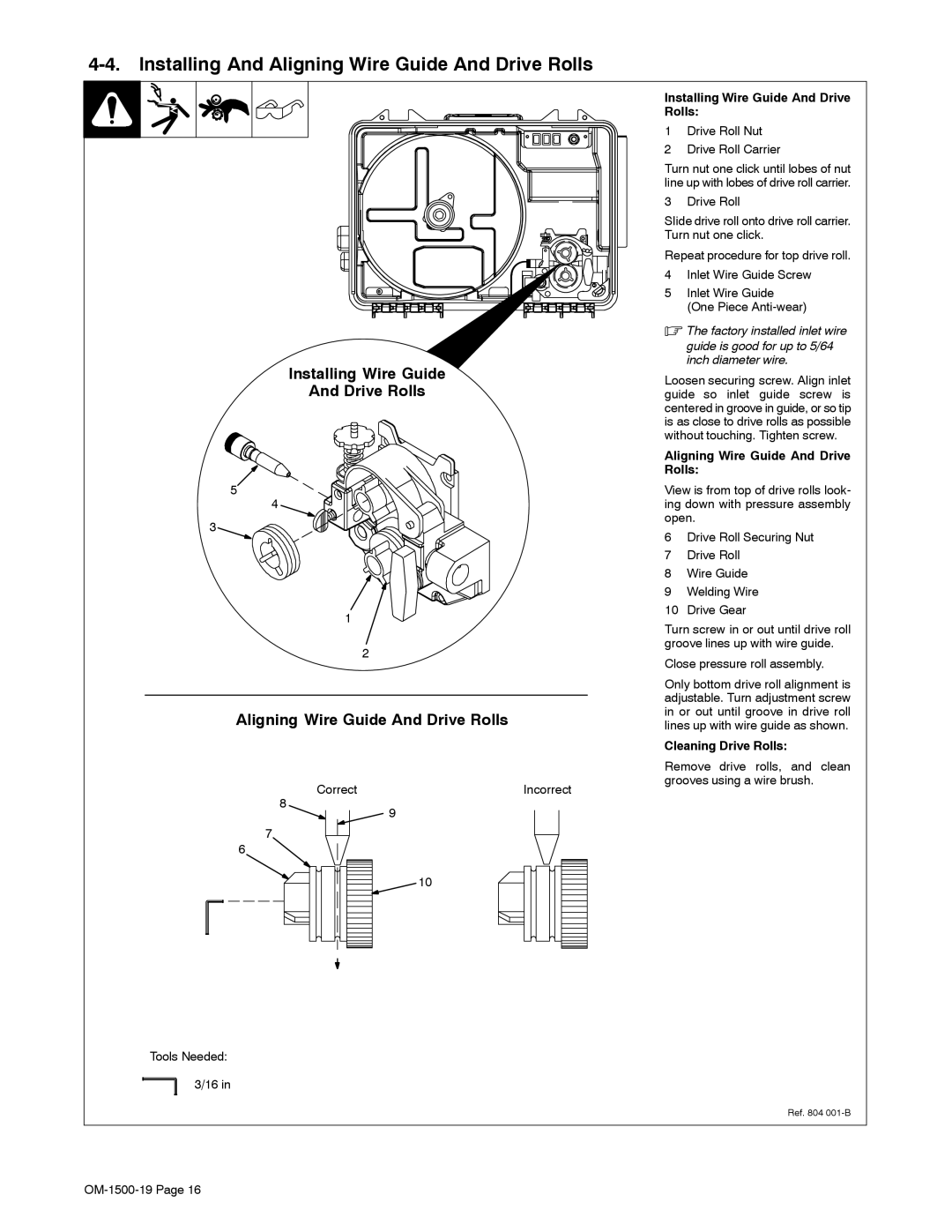

4-4. Installing And Aligning Wire Guide And Drive Rolls

Installing Wire Guide

And Drive Rolls

5

4

3

1

2

Aligning Wire Guide And Drive Rolls

Correct | Incorrect |

8 | 9 |

|

7

6

10

Tools Needed:

3/16 in

Installing Wire Guide And Drive Rolls:

1Drive Roll Nut

2Drive Roll Carrier

Turn nut one click until lobes of nut line up with lobes of drive roll carrier.

3 Drive Roll

Slide drive roll onto drive roll carrier. Turn nut one click.

Repeat procedure for top drive roll.

4Inlet Wire Guide Screw

5Inlet Wire Guide (One Piece

.The factory installed inlet wire

guide is good for up to 5/64 inch diameter wire.

Loosen securing screw. Align inlet guide so inlet guide screw is centered in groove in guide, or so tip is as close to drive rolls as possible without touching. Tighten screw.

Aligning Wire Guide And Drive Rolls:

View is from top of drive rolls look- ing down with pressure assembly open.

6Drive Roll Securing Nut

7Drive Roll

8Wire Guide

9Welding Wire

10Drive Gear

Turn screw in or out until drive roll groove lines up with wire guide.

Close pressure roll assembly.

Only bottom drive roll alignment is adjustable. Turn adjustment screw in or out until groove in drive roll lines up with wire guide as shown.

Cleaning Drive Rolls:

Remove drive rolls, and clean grooves using a wire brush.

Ref. 804