SECTION 4 ± OPERATING WELDING GENERATOR

|

|

|

|

|

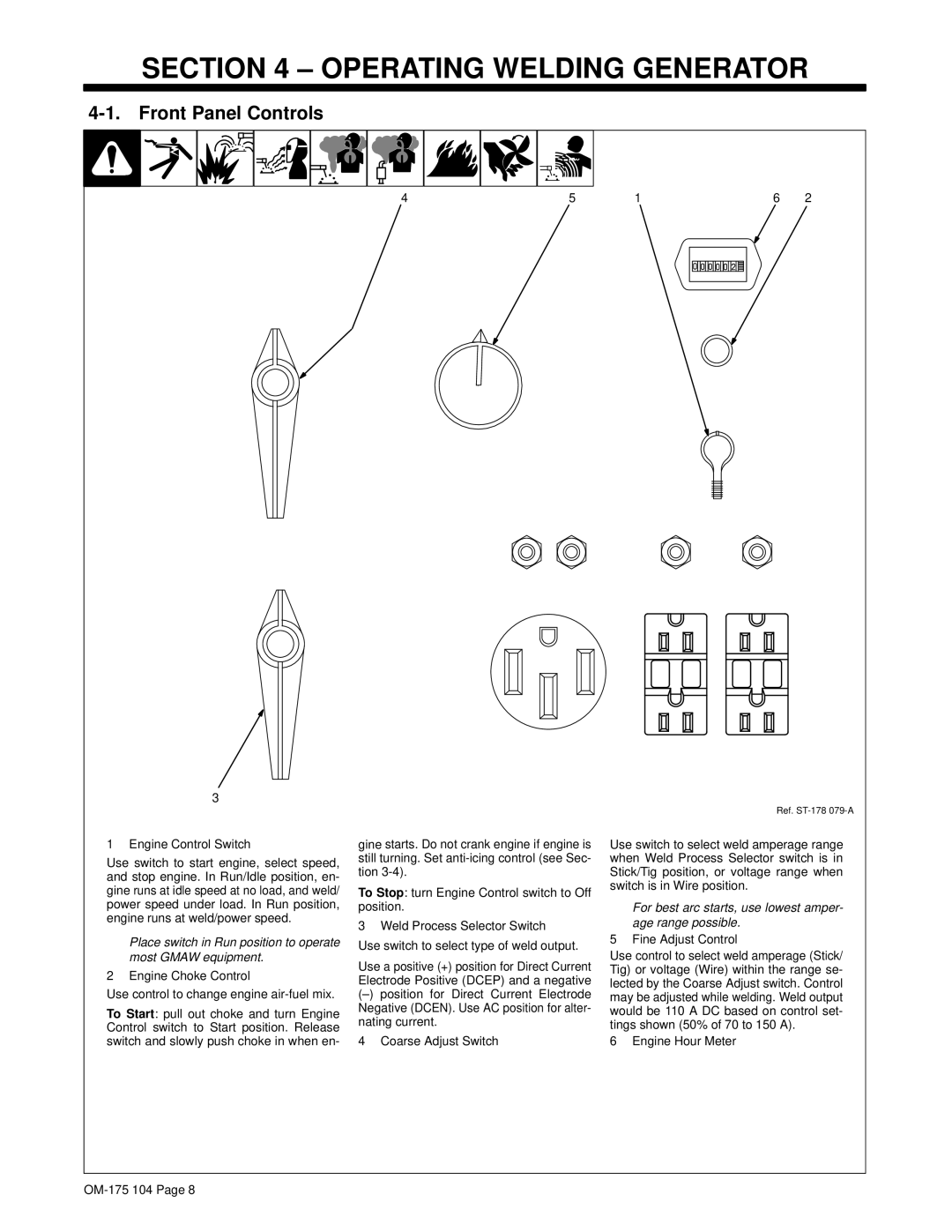

4 | 5 | 1 | 6 | 2 |

3

1 Engine Control Switch

Use switch to start engine, select speed, and stop engine. In Run/Idle position, en- gine runs at idle speed at no load, and weld/ power speed under load. In Run position, engine runs at weld/power speed.

.Place switch in Run position to operate most GMAW equipment.

2 Engine Choke Control

Use control to change engine

To Start: pull out choke and turn Engine Control switch to Start position. Release switch and slowly push choke in when en-

gine starts. Do not crank engine if engine is still turning. Set

To Stop: turn Engine Control switch to Off position.

3 Weld Process Selector Switch

Use switch to select type of weld output.

Use a positive (+) position for Direct Current Electrode Positive (DCEP) and a negative

(±)position for Direct Current Electrode Negative (DCEN). Use AC position for alter- nating current.

4 Coarse Adjust Switch

Ref.

Use switch to select weld amperage range when Weld Process Selector switch is in Stick/Tig position, or voltage range when switch is in Wire position.

.For best arc starts, use lowest amper- age range possible.

5 Fine Adjust Control

Use control to select weld amperage (Stick/ Tig) or voltage (Wire) within the range se- lected by the Coarse Adjust switch. Control may be adjusted while welding. Weld output would be 110 A DC based on control set- tings shown (50% of 70 to 150 A).

6 Engine Hour Meter