SECTION 3 ± INSTALLATION

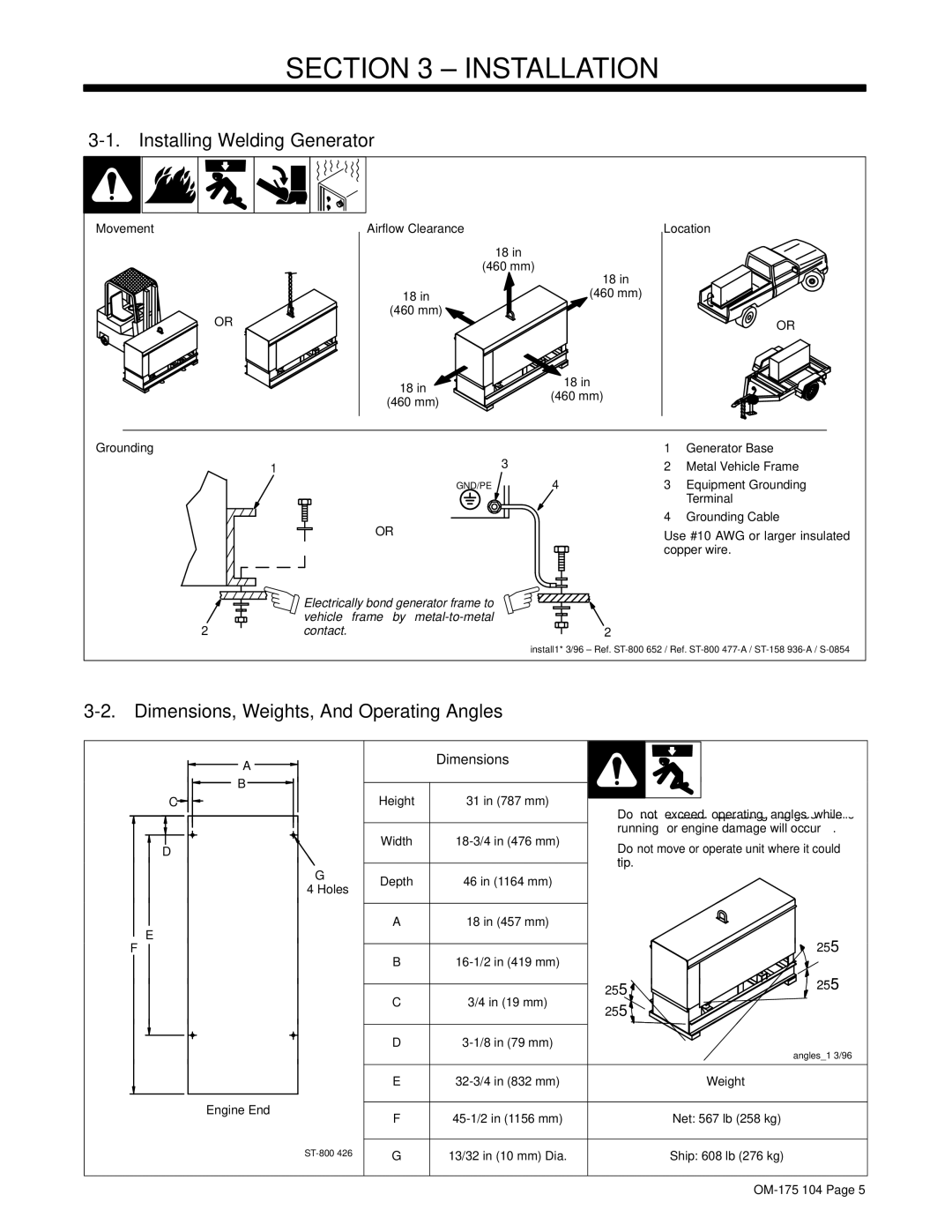

3-1. Installing Welding Generator

Movement

OR

Airflow Clearance

18in

(460 mm)

| 18 in | |

18 in | (460 mm) | |

(460 mm) |

| |

18 in | 18 in | |

(460 mm) | ||

(460 mm) | ||

|

Location

OR

Grounding

2

1 | 3 |

| |

| GND/PE |

OR

Electrically bond generator frame to vehicle frame by

| 1 | Generator Base |

| 2 | Metal Vehicle Frame |

4 | 3 | Equipment Grounding |

|

| Terminal |

| 4 | Grounding Cable |

Use #10 AWG or larger insulated copper wire.

2

install1* 3/96 ± Ref.

3-2. Dimensions, Weights, And Operating Angles

A

![]()

![]() B

B

C ![]()

![]()

D

![]()

![]() E

E

F

Engine End

G

4 Holes

| Dimensions |

|

| |

Height | 31 in (787 mm) | Y Do not exceed operating angles while | ||

|

| |||

Width | running or engine damage will occur. | |||

Y Do not move or operate unit where it could | ||||

|

| |||

|

| tip. |

| |

Depth | 46 in (1164 mm) |

|

| |

A | 18 in (457 mm) |

|

| |

|

|

| 25° | |

B |

|

| ||

|

| 25° | 25° | |

C | 3/4 in (19 mm) |

| ||

25° |

| |||

|

|

| ||

D |

|

| ||

|

|

| angles_1 3/96 | |

E |

| Weight | ||

F |

| Net: 567 lb (258 kg) | ||

G

13/32 in (10 mm) Dia.

Ship: 608 lb (276 kg)