1-4. Additional Installation, Operation, And Maintenance Hazards

WARNING

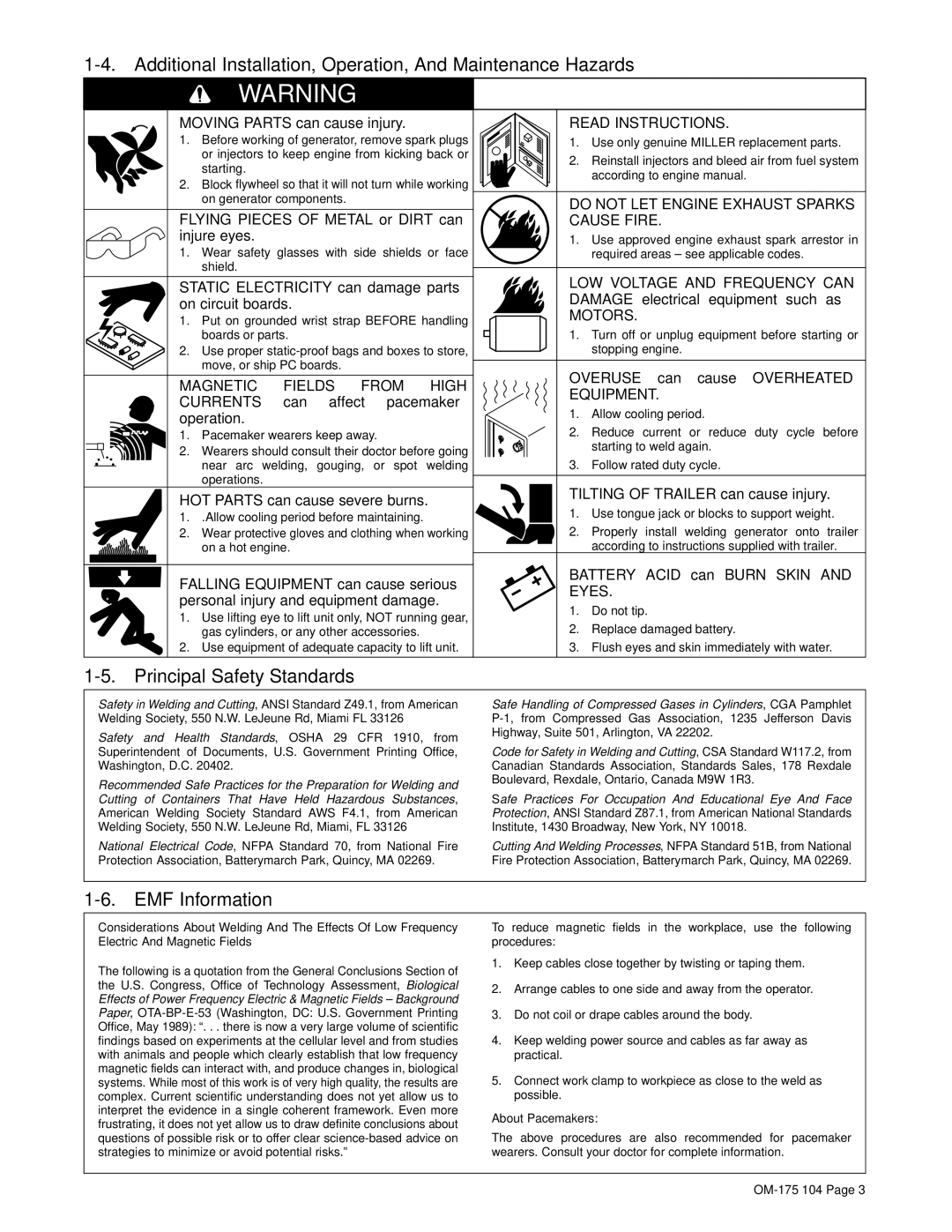

MOVING PARTS can cause injury. |

| READ INSTRUCTIONS. | ||||

1. Before working of generator, remove spark plugs | 1. | Use only genuine MILLER replacement parts. | ||||

or injectors to keep engine from kicking back or | 2. | Reinstall injectors and bleed air from fuel system | ||||

starting. |

|

|

| |||

|

|

|

| according to engine manual. | ||

2. Block flywheel so that it will not turn while working |

| |||||

|

| |||||

on generator components. |

|

| DO NOT LET ENGINE EXHAUST SPARKS | |||

FLYING PIECES OF METAL or DIRT can | ||||||

CAUSE FIRE. | ||||||

injure eyes. |

|

|

| 1. Use approved engine exhaust spark arrestor in | ||

1. Wear safety glasses with side shields or face |

| required areas ± see applicable codes. | ||||

shield. |

|

|

|

|

| |

STATIC ELECTRICITY can damage parts | LOW VOLTAGE AND FREQUENCY CAN | |||||

DAMAGE electrical equipment such as | ||||||

on circuit boards. |

|

| ||||

|

| MOTORS. | ||||

1. Put on grounded wrist strap BEFORE handling | ||||||

1. Turn off or unplug equipment before starting or | ||||||

boards or parts. |

|

| ||||

2. Use proper |

| stopping engine. | ||||

move, or ship PC boards. |

|

| OVERUSE can cause OVERHEATED | |||

MAGNETIC | FIELDS | FROM | HIGH | |||

EQUIPMENT. | ||||||

CURRENTS | can affect pacemaker | |||||

1. | Allow cooling period. | |||||

operation. |

|

|

| |||

1. Pacemaker wearers keep away. |

| 2. | Reduce current or reduce duty cycle before | |||

2. Wearers should consult their doctor before going |

| starting to weld again. | ||||

3. | Follow rated duty cycle. | |||||

near arc welding, gouging, or spot welding | ||||||

operations. |

|

|

| TILTING OF TRAILER can cause injury. | ||

HOT PARTS can cause severe burns. | ||||||

1. Use tongue jack or blocks to support weight. | ||||||

1. .Allow cooling period before maintaining. |

| |||||

| 2. | Properly install welding generator onto trailer | ||||

2. Wear protective gloves and clothing when working | ||||||

on a hot engine. |

|

|

| according to instructions supplied with trailer. | ||

FALLING EQUIPMENT can cause serious | BATTERY ACID can BURN SKIN AND | |||||

EYES. | ||||||

personal injury and equipment damage. | ||||||

1. | Do not tip. | |||||

1. Use lifting eye to lift unit only, NOT running gear, | ||||||

2. | Replace damaged battery. | |||||

gas cylinders, or any other accessories. |

| |||||

2. Use equipment of adequate capacity to lift unit. | 3. | Flush eyes and skin immediately with water. | ||||

|

|

|

| |||

Safety in Welding and Cutting, ANSI Standard Z49.1, from American | Safe Handling of Compressed Gases in Cylinders, CGA Pamphlet | |||||

Welding Society, 550 N.W. LeJeune Rd, Miami FL 33126 |

| |||||

Safety and Health Standards, OSHA 29 CFR 1910, from | Highway, Suite 501, Arlington, VA 22202. | |||||

|

| |||||

Superintendent of Documents, U.S. Government Printing Office, | Code for Safety in Welding and Cutting, CSA Standard W117.2, from | |||||

Washington, D.C. 20402. |

|

|

| Canadian Standards Association, Standards Sales, 178 Rexdale | ||

Recommended Safe Practices for the Preparation for Welding and | Boulevard, Rexdale, Ontario, Canada M9W 1R3. | |||||

|

| |||||

Cutting of Containers That Have Held Hazardous Substances, | Safe Practices For Occupation And Educational Eye And Face | |||||

American Welding Society Standard AWS F4.1, from American | Protection, ANSI Standard Z87.1, from American National Standards | |||||

Welding Society, 550 N.W. LeJeune Rd, Miami, FL 33126 |

| Institute, 1430 Broadway, New York, NY 10018. | ||||

National Electrical Code, NFPA Standard 70, from National Fire | Cutting And Welding Processes, NFPA Standard 51B, from National | |||||

Protection Association, Batterymarch Park, Quincy, MA 02269. | Fire Protection Association, Batterymarch Park, Quincy, MA 02269. | |||||

|

|

|

|

|

| |

Considerations About Welding And The Effects Of Low Frequency | To reduce magnetic fields in the workplace, use the following | |||||

Electric And Magnetic Fields |

|

|

| procedures: |

| |

The following is a quotation from the General Conclusions Section of | 1. Keep cables close together by twisting or taping them. | |||||

|

| |||||

the U.S. Congress, Office of Technology Assessment, Biological | 2. Arrange cables to one side and away from the operator. | |||||

Effects of Power Frequency Electric & Magnetic Fields ± Background | ||||||

|

| |||||

Paper, | 3. Do not coil or drape cables around the body. | |||||

Office, May 1989): ª. . . there is now avery large volume of scientific | 4. Keep welding power source and cables as far away as | |||||

findings based on experiments at the cellular level and from studies | ||||||

with animals and people which clearly establish that low frequency | practical. |

| ||||

magnetic fields can interact with, and produce changes in, biological | 5. Connect work clamp to workpiece as close to the weld as | |||||

systems. While most of this work is of very high quality, the results are | ||||||

complex. Current scientific understanding does not yet allow us to | possible. |

| ||||

interpret the evidence in a single coherent framework. Even more | About Pacemakers: | |||||

frustrating, it does not yet allow us to draw definite conclusions about | ||||||

|

| |||||

questions of possible risk or to offer clear | The above procedures are also recommended for pacemaker | |||||

strategies to minimize or avoid potential risks.º |

|

| wearers. Consult your doctor for complete information. | |||