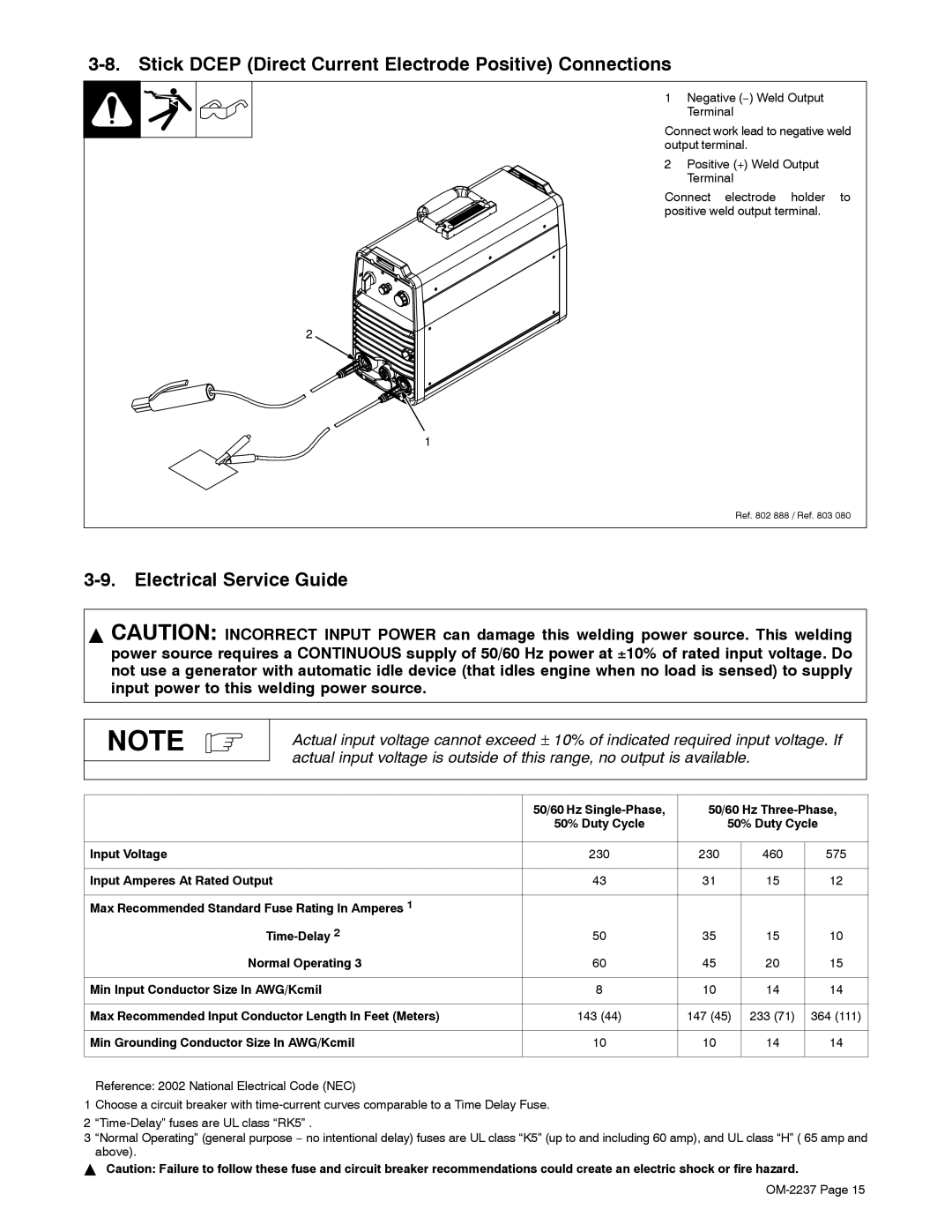

3-8. Stick DCEP (Direct Current Electrode Positive) Connections

1 Negative (−) Weld Output Terminal

Connect work lead to negative weld output terminal.

2 Positive (+) Weld Output Terminal

Connect electrode holder to positive weld output terminal.

2![]()

1

Ref. 802 888 / Ref. 803 080

3-9. Electrical Service Guide

YCAUTION: INCORRECT INPUT POWER can damage this welding power source. This welding power source requires a CONTINUOUS supply of 50/60 Hz power at +10% of rated input voltage. Do not use a generator with automatic idle device (that idles engine when no load is sensed) to supply input power to this welding power source.

NOTE

Actual input voltage cannot exceed ± 10% of indicated required input voltage. If actual input voltage is outside of this range, no output is available.

| 50/60 Hz | 50/60 Hz | ||

| 50% Duty Cycle | 50% Duty Cycle | ||

|

|

|

|

|

Input Voltage | 230 | 230 | 460 | 575 |

|

|

|

|

|

Input Amperes At Rated Output | 43 | 31 | 15 | 12 |

|

|

|

|

|

Max Recommended Standard Fuse Rating In Amperes 1 |

|

|

|

|

50 | 35 | 15 | 10 | |

Normal Operating 3 | 60 | 45 | 20 | 15 |

|

|

|

|

|

Min Input Conductor Size In AWG/Kcmil | 8 | 10 | 14 | 14 |

|

|

|

|

|

Max Recommended Input Conductor Length In Feet (Meters) | 143 (44) | 147 (45) | 233 (71) | 364 (111) |

|

|

|

|

|

Min Grounding Conductor Size In AWG/Kcmil | 10 | 10 | 14 | 14 |

|

|

|

|

|

Reference: 2002 National Electrical Code (NEC)

1Choose a circuit breaker with

2

3“Normal Operating” (general purpose − no intentional delay) fuses are UL class “K5” (up to and including 60 amp), and UL class “H” ( 65 amp and above).

YCaution: Failure to follow these fuse and circuit breaker recommendations could create an electric shock or fire hazard.