the tungsten will become contaminated.

OM-880 Page 20

Do not use same wheel for any other job or

•

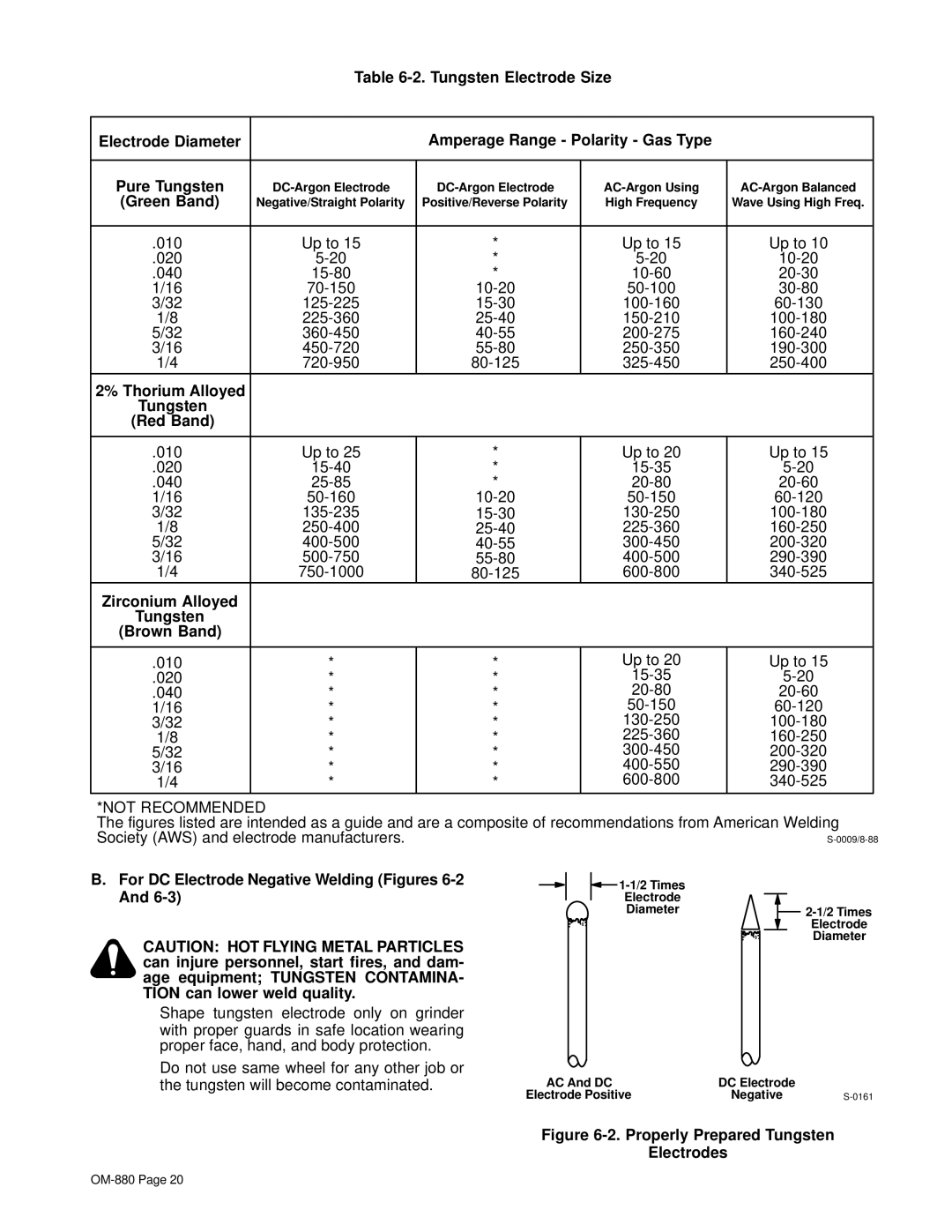

B. For DC Electrode Negative Welding (Figures 6-2 And 6-3)

CAUTION: HOT FLYING METAL PARTICLES can injure personnel, start fires, and dam- age equipment; TUNGSTEN CONTAMINA-

TION can lower weld quality.

• Shape tungsten electrode only on grinder with proper guards in safe location wearing proper face, hand, and body protection.

Table 6-2. Tungsten Electrode Size

Electrode Diameter | | Amperage Range - Polarity - Gas Type | |

| | | | |

Pure Tungsten | DC-Argon Electrode | DC-Argon Electrode | AC-Argon Using | AC-Argon Balanced |

(Green Band) | Negative/Straight Polarity | Positive/Reverse Polarity | High Frequency | Wave Using High Freq. |

| | | | |

.010” | Up to 15 | * | Up to 15 | Up to 10 |

.020” | 5-20 | * | 5-20 | 10-20 |

.040” | 15-80 | * | 10-60 | 20-30 |

1/16” | 70-150 | 10-20 | 50-100 | 30-80 |

3/32” | 125-225 | 15-30 | 100-160 | 60-130 |

1/8” | 225-360 | 25-40 | 150-210 | 100-180 |

5/32” | 360-450 | 40-55 | 200-275 | 160-240 |

3/16” | 450-720 | 55-80 | 250-350 | 190-300 |

1/4” | 720-950 | 80-125 | 325-450 | 250-400 |

2% Thorium Alloyed | | | | |

Tungsten | | | | |

(Red Band) | | | | |

| | | | |

.010” | Up to 25 | * | Up to 20 | Up to 15 |

.020” | 15-40 | * | 15-35 | 5-20 |

.040” | 25-85 | * | 20-80 | 20-60 |

1/16” | 50-160 | 10-20 | 50-150 | 60-120 |

3/32” | 135-235 | 15-30 | 130-250 | 100-180 |

1/8” | 250-400 | 25-40 | 225-360 | 160-250 |

5/32” | 400-500 | 40-55 | 300-450 | 200-320 |

3/16” | 500-750 | 55-80 | 400-500 | 290-390 |

1/4” | 750-1000 | 80-125 | 600-800 | 340-525 |

Zirconium Alloyed | | | | |

Tungsten | | | | |

(Brown Band) | | | | |

| | | | |

.010” | * | * | Up to 20 | Up to 15 |

.020” | * | * | 15-35 | 5-20 |

.040” | * | * | 20-80 | 20-60 |

1/16” | * | * | 50-150 | 60-120 |

3/32” | * | * | 130-250 | 100-180 |

1/8” | * | * | 225-360 | 160-250 |

5/32” | * | * | 300-450 | 200-320 |

3/16” | * | * | 400-550 | 290-390 |

1/4” | * | * | 600-800 | 340-525 |

*NOT RECOMMENDED

The figures listed are intended as a guide and are a composite of recommendations from American Welding

Society (AWS) and electrode manufacturers. | S-0009/8-88 |

1-1/2 Times

Electrode

Diameter

2-1/2 Times

Electrode

Diameter

AC And DC | DC Electrode | |

Electrode Positive | Negative | S-0161 |

Figure 6-2. Properly Prepared Tungsten

Electrodes