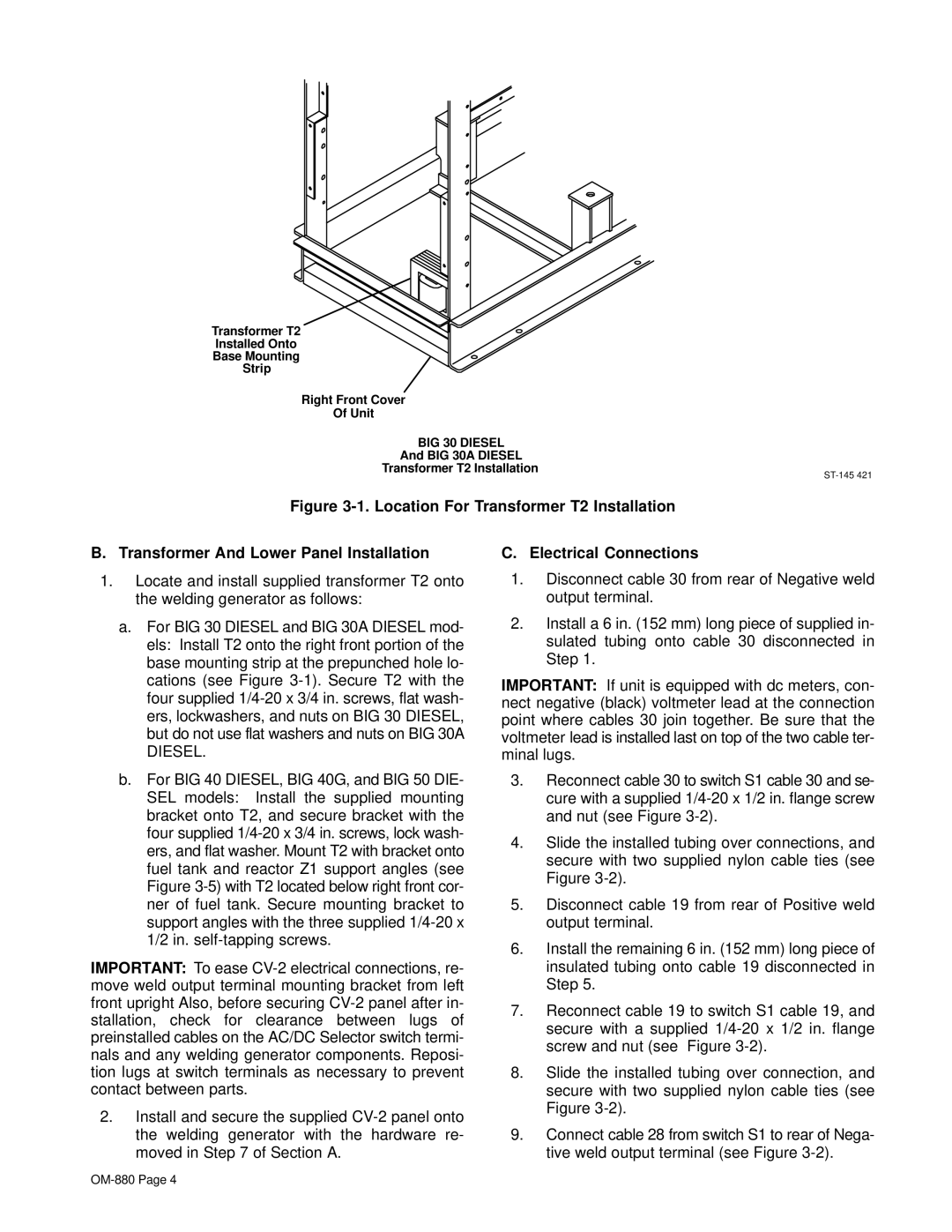

Transformer T2

Installed Onto

Base Mounting

Strip

Right Front Cover

Of Unit

BIG 30 DIESEL

And BIG 30A DIESEL

Transformer T2 Installation

Figure 3-1. Location For Transformer T2 Installation

B. Transformer And Lower Panel Installation | C. Electrical Connections |

1.Locate and install supplied transformer T2 onto the welding generator as follows:

a.For BIG 30 DIESEL and BIG 30A DIESEL mod- els: Install T2 onto the right front portion of the base mounting strip at the prepunched hole lo- cations (see Figure

b.For BIG 40 DIESEL, BIG 40G, and BIG 50 DIE- SEL models: Install the supplied mounting bracket onto T2, and secure bracket with the four supplied

IMPORTANT: To ease

2.Install and secure the supplied

1.Disconnect cable 30 from rear of Negative weld output terminal.

2.Install a 6 in. (152 mm) long piece of supplied in- sulated tubing onto cable 30 disconnected in Step 1.

IMPORTANT: If unit is equipped with dc meters, con- nect negative (black) voltmeter lead at the connection point where cables 30 join together. Be sure that the voltmeter lead is installed last on top of the two cable ter- minal lugs.

3.Reconnect cable 30 to switch S1 cable 30 and se- cure with a supplied

4.Slide the installed tubing over connections, and secure with two supplied nylon cable ties (see Figure

5.Disconnect cable 19 from rear of Positive weld output terminal.

6.Install the remaining 6 in. (152 mm) long piece of insulated tubing onto cable 19 disconnected in Step 5.

7.Reconnect cable 19 to switch S1 cable 19, and secure with a supplied

8.Slide the installed tubing over connection, and secure with two supplied nylon cable ties (see Figure

9.Connect cable 28 from switch S1 to rear of Nega- tive weld output terminal (see Figure