SECTION 5 − OPERATION

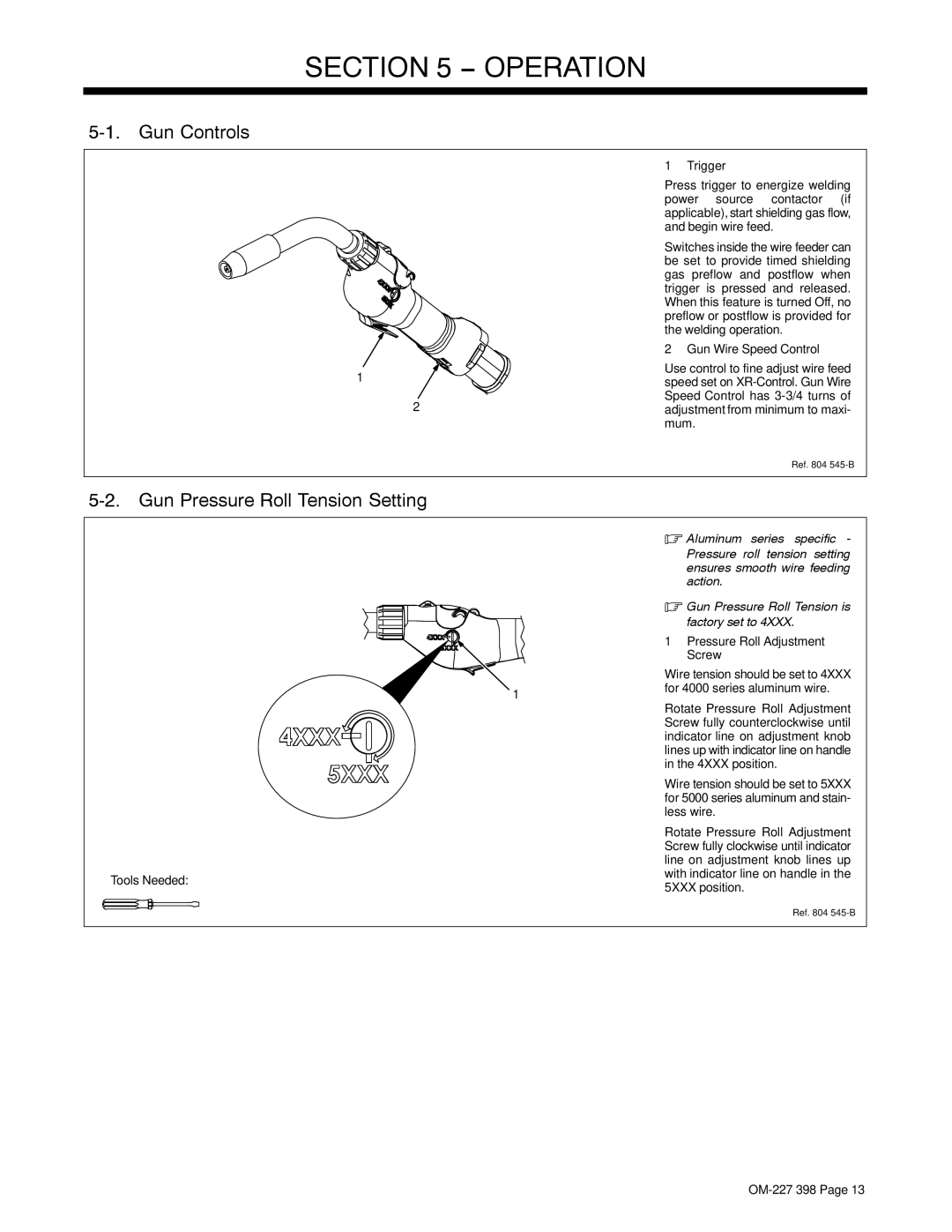

5-1. Gun Controls

1 Trigger

1![]()

2

Press trigger to energize welding power source contactor (if applicable), start shielding gas flow, and begin wire feed.

Switches inside the wire feeder can be set to provide timed shielding gas preflow and postflow when trigger is pressed and released. When this feature is turned Off, no preflow or postflow is provided for the welding operation.

2 Gun Wire Speed Control

Use control to fine adjust wire feed speed set on

Ref. 804

5-2. Gun Pressure Roll Tension Setting

. Aluminum series specific - Pressure roll tension setting ensures smooth wire feeding

|

| action. |

|

| . Gun Pressure Roll Tension is |

|

| factory set to 4XXX. |

|

| 1 Pressure Roll Adjustment |

|

| Screw |

|

| Wire tension should be set to 4XXX |

| 1 | for 4000 series aluminum wire. |

| Rotate Pressure Roll Adjustment | |

|

| |

|

| Screw fully counterclockwise until |

|

| indicator line on adjustment knob |

|

| lines up with indicator line on handle |

|

| in the 4XXX position. |

|

| Wire tension should be set to 5XXX |

|

| for 5000 series aluminum and stain- |

|

| less wire. |

|

| Rotate Pressure Roll Adjustment |

|

| Screw fully clockwise until indicator |

|

| line on adjustment knob lines up |

Tools Needed: |

| with indicator line on handle in the |

| 5XXX position. | |

|

| |

|

| Ref. 804 |