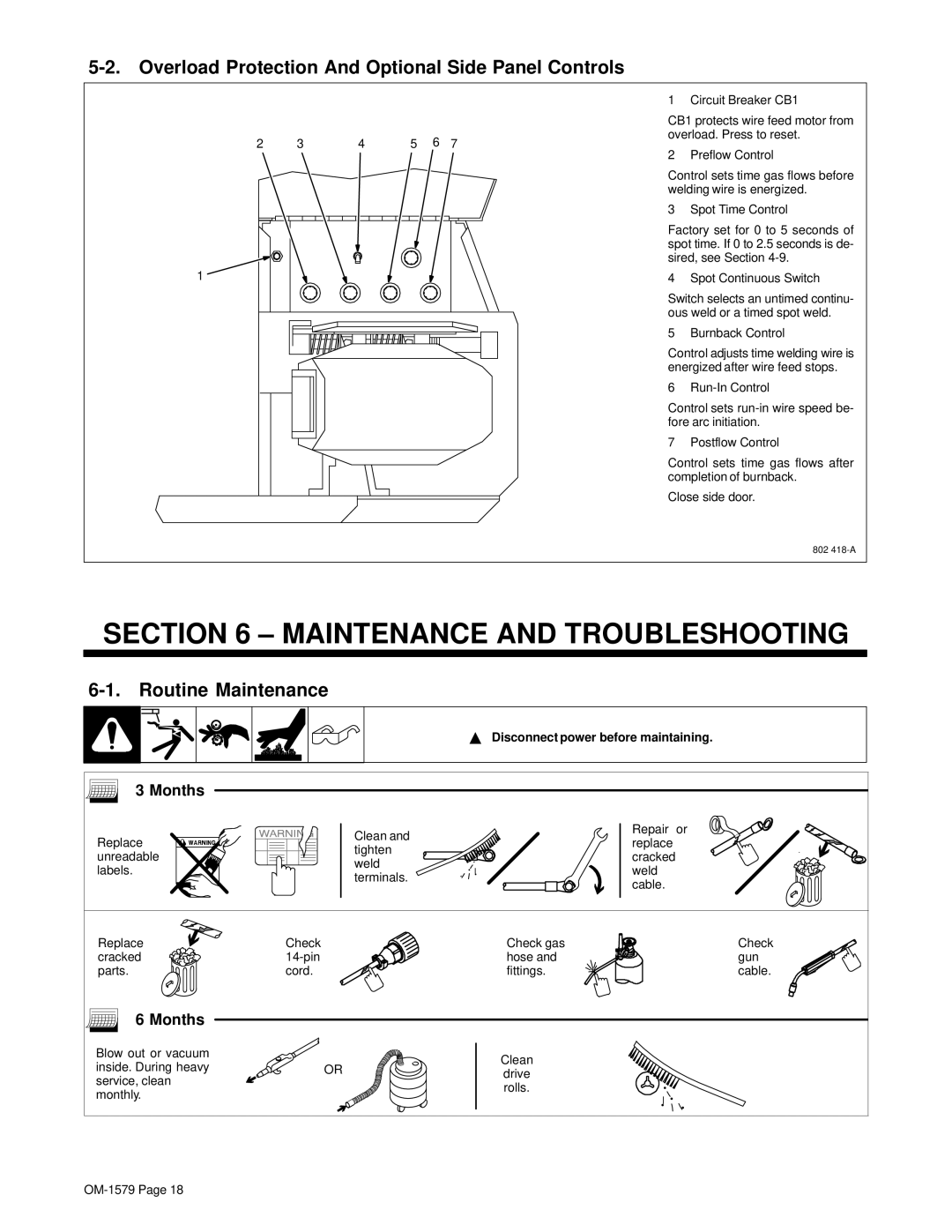

5-2. Overload Protection And Optional Side Panel Controls

|

|

|

|

| 1 | Circuit Breaker CB1 |

|

|

|

|

| CB1 protects wire feed motor from | |

2 | 3 | 4 | 5 | 6 | overload. Press to reset. | |

7 | Preflow Control | |||||

|

|

|

|

| 2 | |

|

|

|

|

| Control sets time gas flows before | |

|

|

|

|

| welding wire is energized. | |

|

|

|

|

| 3 | Spot Time Control |

|

|

|

|

| Factory set for 0 to 5 seconds of | |

|

|

|

|

| spot time. If 0 to 2.5 seconds is de- | |

|

|

|

|

| sired, see Section | |

1 |

|

|

|

| 4 | Spot Continuous Switch |

|

|

|

|

| Switch selects an untimed continu- | |

|

|

|

|

| ous weld or a timed spot weld. | |

|

|

|

|

| 5 | Burnback Control |

|

|

|

|

| Control adjusts time welding wire is | |

|

|

|

|

| energized after wire feed stops. | |

|

|

|

|

| 6 | |

|

|

|

|

| Control sets | |

|

|

|

|

| fore arc initiation. | |

|

|

|

|

| 7 | Postflow Control |

Control sets time gas flows after completion of burnback.

Close side door.

802

SECTION 6 – MAINTENANCE AND TROUBLESHOOTING

6-1. Routine Maintenance

Y Disconnect power before maintaining.

3 Months |

|

|

|

|

|

Replace |

|

| Clean and | Repair | or |

|

| replace |

| ||

|

| tighten |

| ||

unreadable |

|

| cracked |

| |

|

| weld |

| ||

labels. |

|

| weld |

| |

|

| terminals. |

| ||

|

|

| cable. |

| |

|

|

|

|

| |

Replace | Check |

|

| Check gas | Check |

cracked |

|

| hose and | gun | |

parts. | cord. |

|

| fittings. | cable. |

6 Months |

|

|

|

|

|

Blow out or vacuum |

|

|

| Clean |

|

inside. During heavy |

| OR |

|

| |

|

| drive |

| ||

service, clean |

|

|

|

| |

|

|

| rolls. |

| |

monthly. |

|

|

|

| |

|

|

|

|

| |

|

|

|

|

|