SECTION 3 – INTRODUCTION

3-1. Specifications

Type of Input | Welding Power | Wire Feed | Wire Diameter | Welding | IP | Overall |

| |

Circuit | Weight | |||||||

Power | Source Type | Speed Range | Range | Rating | Dimensions | |||

Rating |

| |||||||

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| |

|

| Standard: 50 To | .023 To 1/8 in | 100 Volts, |

| Length: |

| |

|

| 780 ipm (1.3 To |

|

| ||||

24 Volts AC | Constant Voltage (CV) | 19.8 mpm) | (0.6 To 3.2 mm) | 750 |

| (673 mm) |

| |

|

| Amperes, |

| Width: 14 in | 45 lb | |||

DC With |

|

| IP 21 | |||||

10 Amperes | Optional High | Max Spool | 100% Duty | (356 mm) | (20 kg) | |||

Contactor Control |

| |||||||

50/60 Hertz | Speed: 90 To | Weight: 60 lb | Cycle |

| Height: 14 in |

| ||

|

|

| ||||||

|

| 1400 ipm (2.3 To | (27 kg) |

|

|

| ||

|

|

|

| (356 mm) |

| |||

|

| 35.6 mpm) |

|

|

|

| ||

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

SECTION 4 – INSTALLATION

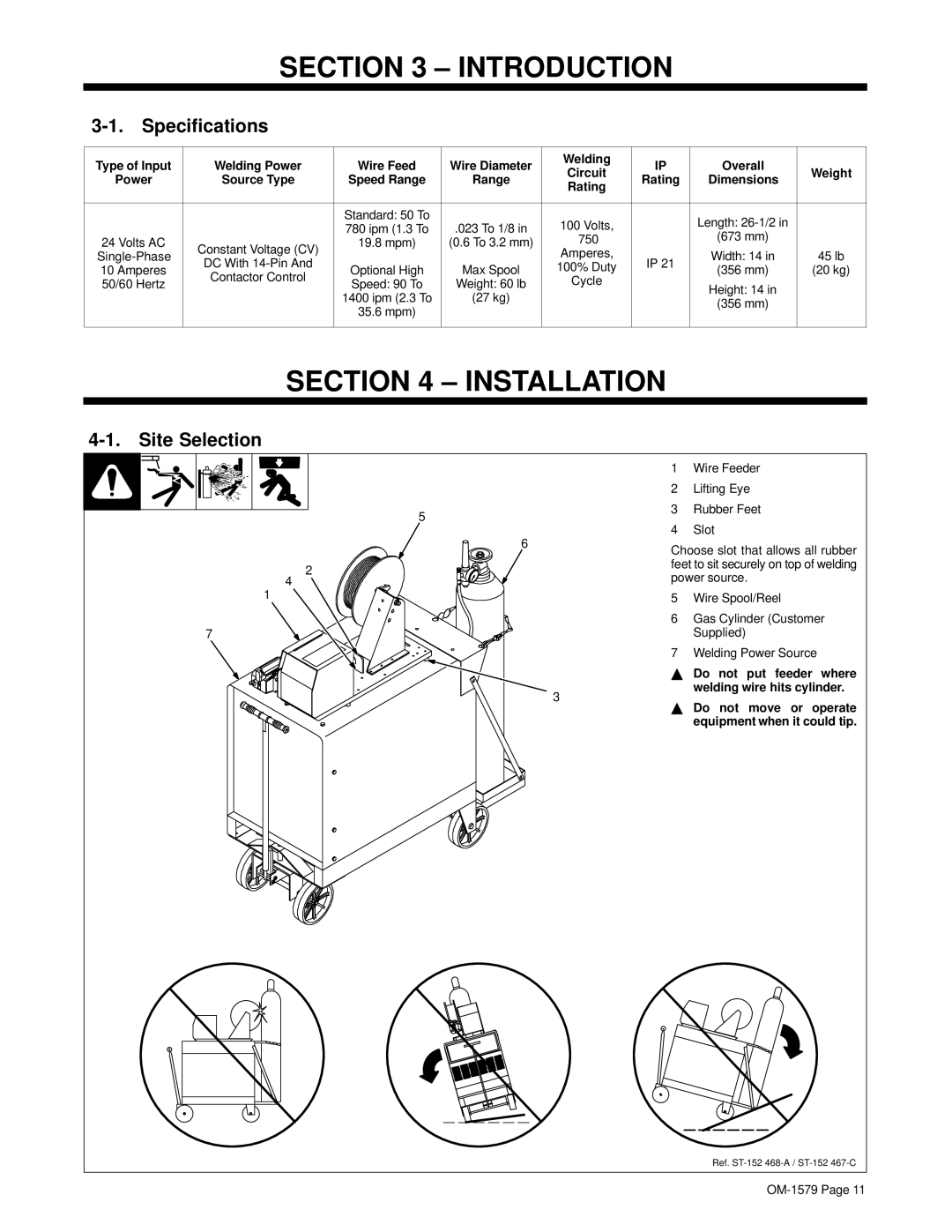

4-1. Site Selection

5

6

2

4

1

7

3

1Wire Feeder

2Lifting Eye

3Rubber Feet

4Slot

Choose slot that allows all rubber feet to sit securely on top of welding power source.

5Wire Spool/Reel

6Gas Cylinder (Customer Supplied)

7Welding Power Source

YDo not put feeder where welding wire hits cylinder.

YDo not move or operate equipment when it could tip.

Ref.