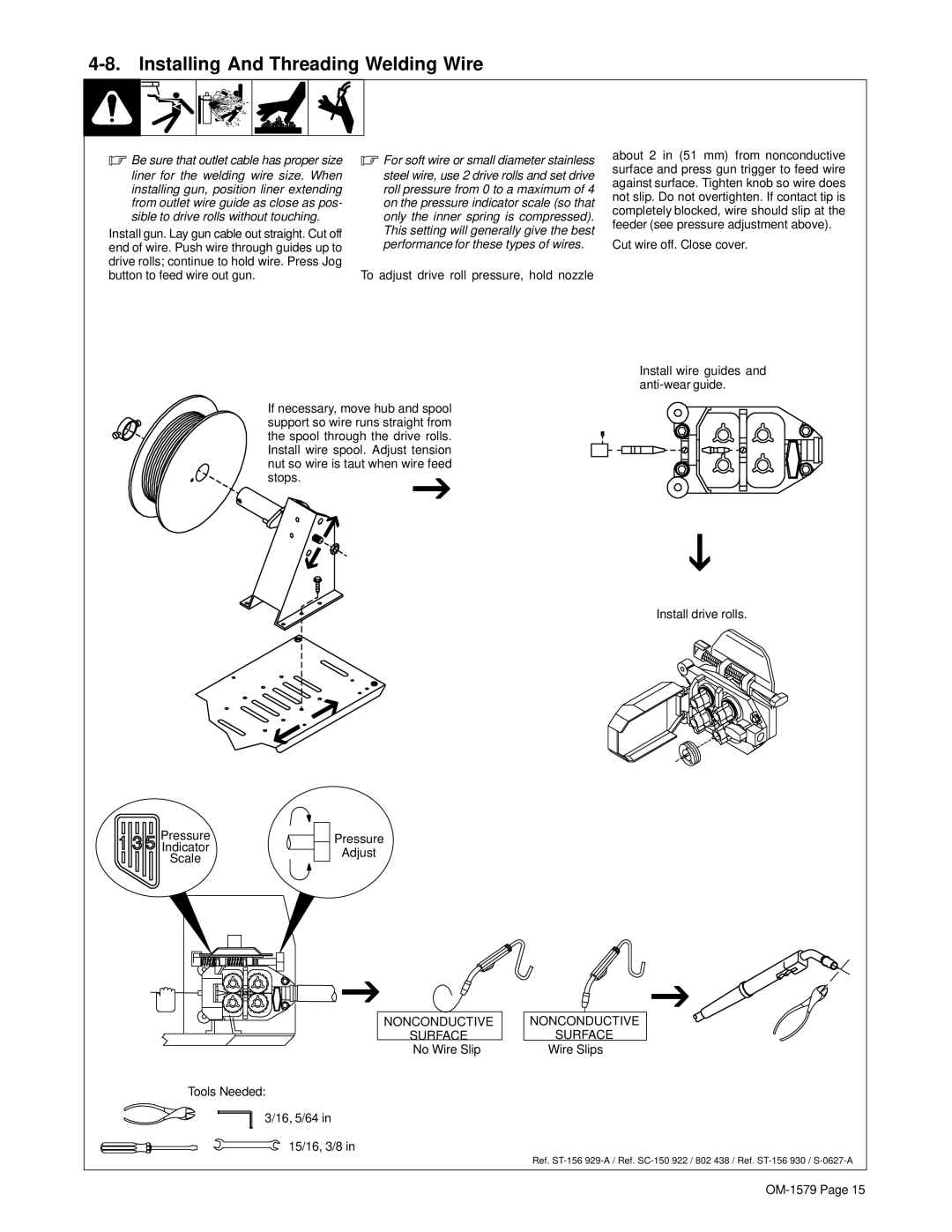

4-8. Installing And Threading Welding Wire

.Be sure that outlet cable has proper size liner for the welding wire size. When installing gun, position liner extending from outlet wire guide as close as pos- sible to drive rolls without touching.

Install gun. Lay gun cable out straight. Cut off end of wire. Push wire through guides up to drive rolls; continue to hold wire. Press Jog button to feed wire out gun.

.For soft wire or small diameter stainless steel wire, use 2 drive rolls and set drive roll pressure from 0 to a maximum of 4 on the pressure indicator scale (so that only the inner spring is compressed). This setting will generally give the best performance for these types of wires.

To adjust drive roll pressure, hold nozzle

about 2 in (51 mm) from nonconductive surface and press gun trigger to feed wire against surface. Tighten knob so wire does not slip. Do not overtighten. If contact tip is completely blocked, wire should slip at the feeder (see pressure adjustment above).

Cut wire off. Close cover.

Install wire guides and

If necessary, move hub and spool support so wire runs straight from the spool through the drive rolls. Install wire spool. Adjust tension nut so wire is taut when wire feed stops.![]()

Pressure | Pressure | |

Indicator | Adjust | |

Scale | ||

|

NONCONDUCTIVE

SURFACE

No Wire Slip

Tools Needed:

3/16, 5/64 in

15/16, 3/8 in

Install drive rolls.

NONCONDUCTIVE

SURFACE

Wire Slips

Ref.