5![]()

![]()

1

| I J | K | A |

Input Power Cord |

|

| B |

|

| L C | |

ConnectionTo | H | N | |

G | M | D | |

| |||

3 | F | E |

|

|

|

| |

2 | 5 |

|

|

|

|

| |

4 |

|

|

|

1 |

|

|

|

1 |

|

|

|

| 5 |

|

|

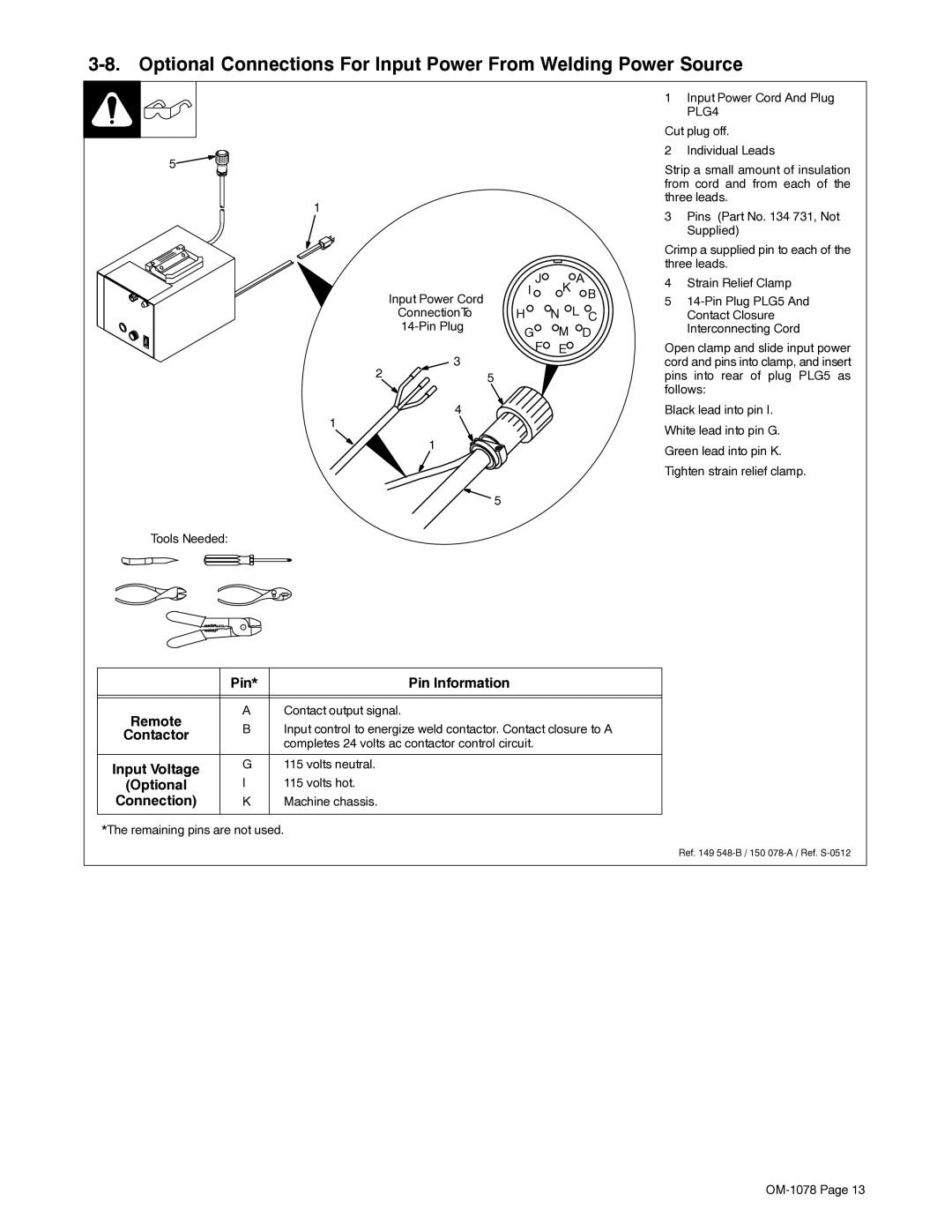

1Input Power Cord And Plug PLG4

Cut plug off.

2 Individual Leads

Strip a small amount of insulation from cord and from each of the three leads.

3Pins (Part No. 134 731, Not Supplied)

Crimp a supplied pin to each of the three leads.

4Strain Relief Clamp

5

Open clamp and slide input power cord and pins into clamp, and insert pins into rear of plug PLG5 as follows:

Black lead into pin I. White lead into pin G. Green lead into pin K. Tighten strain relief clamp.

Tools Needed:

| Pin* | Pin Information | |

|

|

| |

|

|

| |

Remote | A | Contact output signal. | |

B | Input control to energize weld contactor. Contact closure to A | ||

Contactor | |||

| completes 24 volts ac contactor control circuit. | ||

|

| ||

|

|

| |

Input Voltage | G | 115 volts neutral. | |

I | 115 volts hot. | ||

(Optional | |||

Connection) | K | Machine chassis. | |

|

|

|

*The remaining pins are not used.

Ref. 149