Installing Caulk or Adhesive Tube

Always check tubes for punctures or damage before installing. Do not use a damaged or frozen tube.

1.Push the control switch to the Rack Release position. Remove the battery pack.

2.Cut nozzle of tube at an angle and size per manufacturer's recommendation to suit the job (unless the nozzle is

3.Break the inner seal of the tube. If the inner seal is not broken, the caulk material may be forced out the rear end of the tube and damage the tool.

NOTE: Before using a partially filled tube, re- move any hardened material with a long nail or piece of wire.

4.Pull the rod handle back to allow the tube to fit inside the carriage.

![]() WARNING To reduce the risk of injury, keep hands out of the piston area of the tool. Fingers can be pinched between carriage and the piston.

WARNING To reduce the risk of injury, keep hands out of the piston area of the tool. Fingers can be pinched between carriage and the piston.

5.Insert tube into the carriage.

6.Push the rod handle forward until the piston is against the tube.

7.Push the control switch to the Forward position.

8.To remove the tube, push the control switch to the Rack Release position and pull the rod handle back. Lift the tube out of the carriage.

Installing Sausage Type Pack

Always check sausage packs for punctures or damage before installing. Do not use a damaged or frozen pack.

1.Push the control switch to the Rack Release position. Remove the battery pack.

2.Pull the rod handle back to allow the pack to fit inside the barrel

3.Insert pack into barrel.

4.Cut off end of sausage pack per manufacturer's recommendation.

NOTE: Before using a partially filled pack, re- move any hardened material.

5.Insert nozzle supplied with the sausage pack into the nozzle cap and screw onto the barrel

6.Cut nozzle at an angle and size per manufac- turer's recommendation to suit the job (unless the nozzle is

7.Push the rod handle forward until the piston is against the pack.

8.Push the control switch to the Forward position.

OPERATION

![]() WARNING Always remove battery pack before changing or removing acces- sories. Only use accessories specifically recommended for this tool. Others may be hazardous.

WARNING Always remove battery pack before changing or removing acces- sories. Only use accessories specifically recommended for this tool. Others may be hazardous.

![]() WARNING To reduce the risk of in- jury, keep hands away from all moving parts. Always wear safety goggles or glasses with side shields.

WARNING To reduce the risk of in- jury, keep hands away from all moving parts. Always wear safety goggles or glasses with side shields.

Fuel Gauge

To determine the amount of charge left in the bat- tery, pull the trigger. The Fuel Gauge will light up for

To signal the end of charge, 1 light on the fuel gauge will flash for

The caulk gun features an automatic

End of travel

When a tube is emptied, the motor will automatically reverse to release pressure, then shut off. Release the trigger and change the tube.

Overload

When an overload occurs, the tool will reach the maximum drive force and continue to hold this maximum force until the user releases the trigger. If material is not dispensing, make sure that:

•Nozzle tip is cut

•Inner seal in the caulk tube is broken

•Hardened material is removed from the nozzle

•Caulk tube is not damaged or frozen

•Rod is free of caulk/adhesive materials

Starting and Stopping and Controlling Speed

1.Pull trigger to dispense material.

2.Increase or decrease pressure on the trigger to dispense the material. Adjust the speed dial to select the maximum speed for proper bead width and material flow rate ("1" for slowest, "6" for fastest). The trigger pressure, selected speed, material type, temperature and nozzle diameter will all affect the flow rate. When using a tube or pack with a smaller nozzle diameter use a slower speed or the material may be forced around the rear tube seat.

NOTE: Operating the gun at high speeds may damage the dispensing tube or pack for some materials. For best results, gradually increase speed settings.

3.Release trigger to stop dispensing material. NOTE: The piston will stop automatically when it has reached the end of the tube.

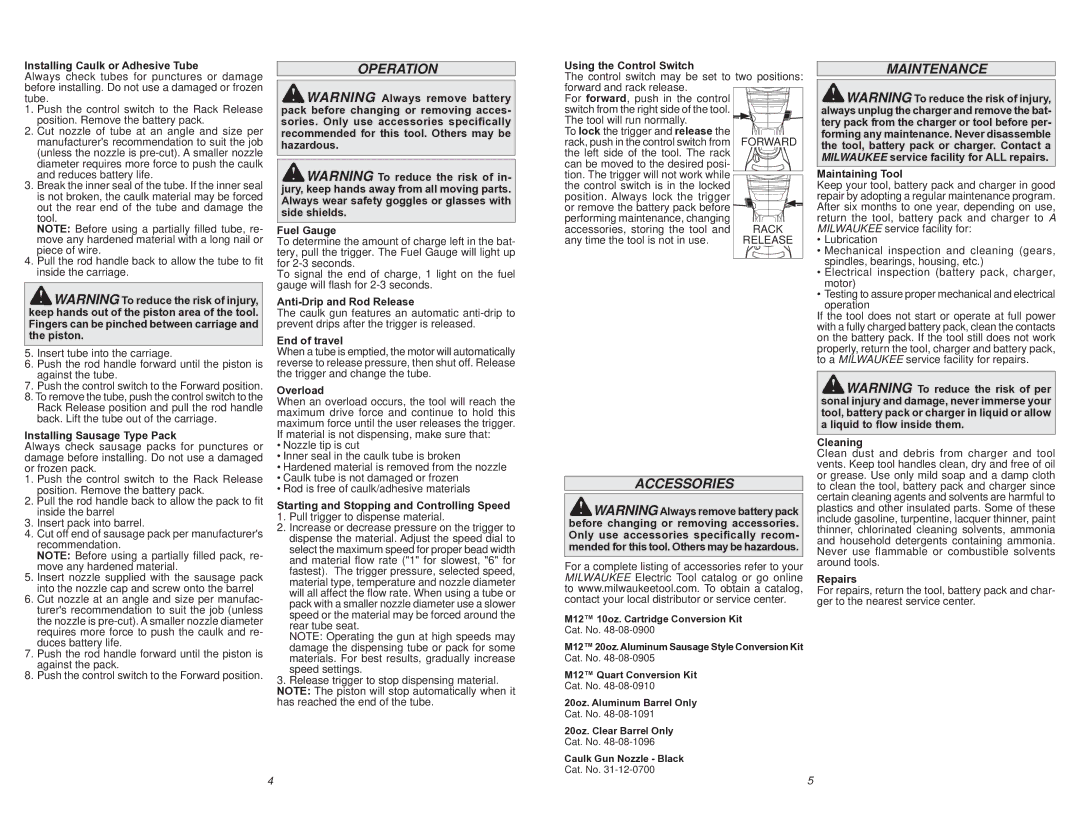

Using the Control Switch

The control switch may be set to two positions: forward and rack release. ![]() For forward, push in the control

For forward, push in the control ![]()

![]()

![]()

![]() switch from the right side of the tool.

switch from the right side of the tool. ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() The tool will run normally.

The tool will run normally. ![]()

![]()

![]()

![]()

![]()

![]()

![]() To lock the trigger and release the

To lock the trigger and release the ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() rack, push in the control switch from

rack, push in the control switch from ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() the left side of the tool. The rack

the left side of the tool. The rack ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() can be moved to the desired posi-

can be moved to the desired posi- ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() tion. The trigger will not work while

tion. The trigger will not work while ![]() the control switch is in the locked

the control switch is in the locked ![]()

![]()

![]()

![]()

![]() position. Always lock the trigger

position. Always lock the trigger ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() or remove the battery pack before

or remove the battery pack before ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() performing maintenance, changing

performing maintenance, changing ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() accessories, storing the tool and

accessories, storing the tool and ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() any time the tool is not in use.

any time the tool is not in use. ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

ACCESSORIES

![]() WARNING Always remove battery pack before changing or removing accessories. Only use accessories specifically recom- mended for this tool. Others may be hazardous.

WARNING Always remove battery pack before changing or removing accessories. Only use accessories specifically recom- mended for this tool. Others may be hazardous.

For a complete listing of accessories refer to your MILWAUKEE Electric Tool catalog or go online to www.milwaukeetool.com. To obtain a catalog, contact your local distributor or service center.

M12™ 10oz. Cartridge Conversion Kit

Cat. No.

M12™ 20oz. Aluminum Sausage Style Conversion Kit

Cat. No.

M12™ Quart Conversion Kit

Cat. No.

20oz. Aluminum Barrel Only

Cat. No.

20oz. Clear Barrel Only

Cat. No.

Caulk Gun Nozzle - Black

Cat. No.

MAINTENANCE

![]() WARNING To reduce the risk of injury, always unplug the charger and remove the bat- tery pack from the charger or tool before per- forming any maintenance. Never disassemble the tool, battery pack or charger. Contact a MILWAUKEE service facility for ALL repairs.

WARNING To reduce the risk of injury, always unplug the charger and remove the bat- tery pack from the charger or tool before per- forming any maintenance. Never disassemble the tool, battery pack or charger. Contact a MILWAUKEE service facility for ALL repairs.

Maintaining Tool

Keep your tool, battery pack and charger in good repair by adopting a regular maintenance program. After six months to one year, depending on use, return the tool, battery pack and charger to A MILWAUKEE service facility for:

•Lubrication

•Mechanical inspection and cleaning (gears, spindles, bearings, housing, etc.)

•Electrical inspection (battery pack, charger, motor)

•Testing to assure proper mechanical and electrical operation

If the tool does not start or operate at full power with a fully charged battery pack, clean the contacts on the battery pack. If the tool still does not work properly, return the tool, charger and battery pack, to a MILWAUKEE service facility for repairs.

![]() WARNING To reduce the risk of per sonal injury and damage, never immerse your tool, battery pack or charger in liquid or allow a liquid to flow inside them.

WARNING To reduce the risk of per sonal injury and damage, never immerse your tool, battery pack or charger in liquid or allow a liquid to flow inside them.

Cleaning

Clean dust and debris from charger and tool vents. Keep tool handles clean, dry and free of oil or grease. Use only mild soap and a damp cloth to clean the tool, battery pack and charger since certain cleaning agents and solvents are harmful to plastics and other insulated parts. Some of these include gasoline, turpentine, lacquer thinner, paint thinner, chlorinated cleaning solvents, ammonia and household detergents containing ammonia. Never use flammable or combustible solvents around tools.

Repairs

For repairs, return the tool, battery pack and char- ger to the nearest service center.

4 | 5 |