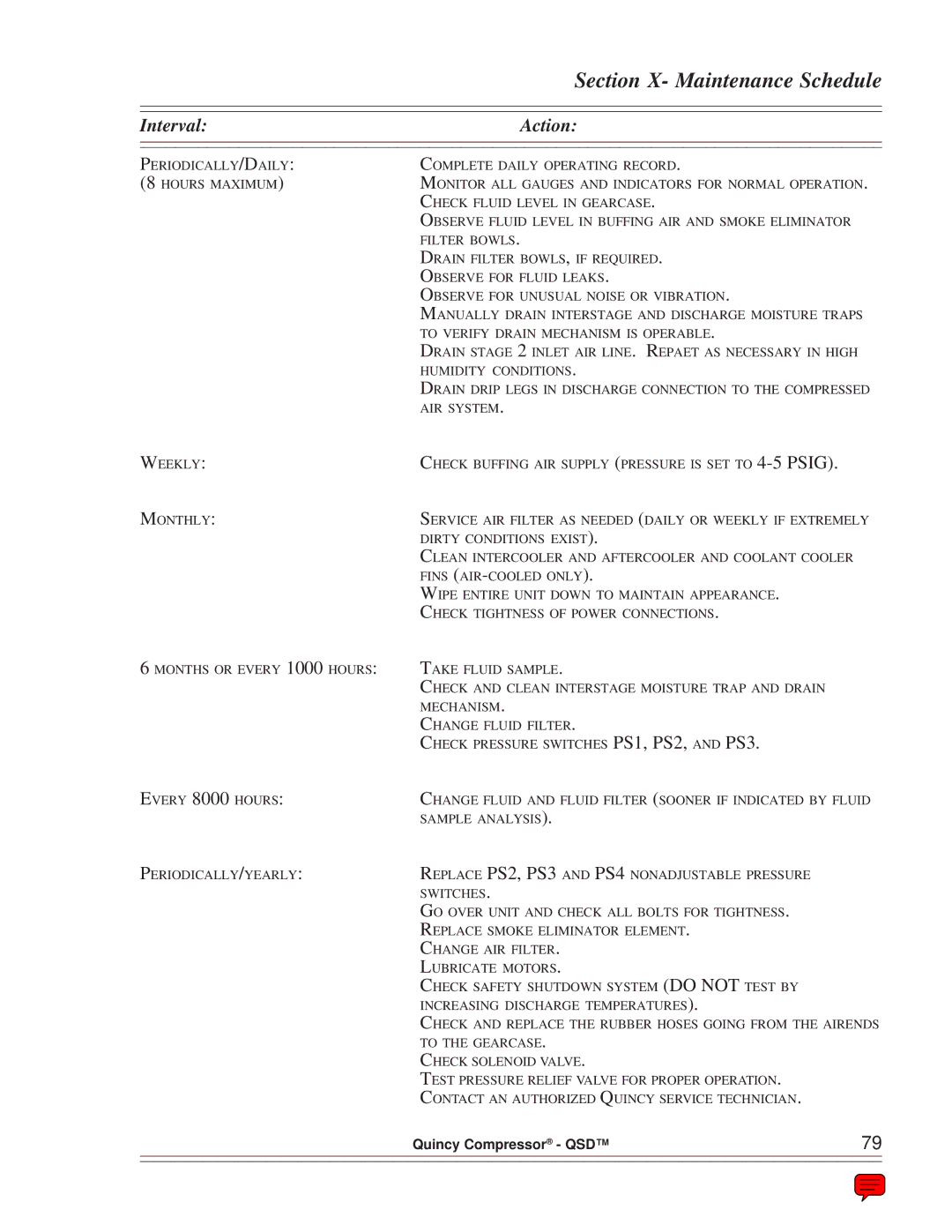

| Section X- Maintenance Schedule |

|

|

|

|

Interval: | Action: |

|

|

|

|

PERIODICALLY/DAILY: | COMPLETE DAILY OPERATING RECORD. |

(8 HOURS MAXIMUM) | MONITOR ALL GAUGES AND INDICATORS FOR NORMAL OPERATION. |

| CHECK FLUID LEVEL IN GEARCASE. |

| OBSERVE FLUID LEVEL IN BUFFING AIR AND SMOKE ELIMINATOR |

| FILTER BOWLS. |

| DRAIN FILTER BOWLS, IF REQUIRED. |

| OBSERVE FOR FLUID LEAKS. |

| OBSERVE FOR UNUSUAL NOISE OR VIBRATION. |

| MANUALLY DRAIN INTERSTAGE AND DISCHARGE MOISTURE TRAPS |

| TO VERIFY DRAIN MECHANISM IS OPERABLE. |

| DRAIN STAGE 2 INLET AIR LINE. REPAET AS NECESSARY IN HIGH |

| HUMIDITY CONDITIONS. |

| DRAIN DRIP LEGS IN DISCHARGE CONNECTION TO THE COMPRESSED |

| AIR SYSTEM. |

WEEKLY: | CHECK BUFFING AIR SUPPLY (PRESSURE IS SET TO |

MONTHLY: | SERVICE AIR FILTER AS NEEDED (DAILY OR WEEKLY IF EXTREMELY |

| DIRTY CONDITIONS EXIST). |

| CLEAN INTERCOOLER AND AFTERCOOLER AND COOLANT COOLER |

| FINS |

| WIPE ENTIRE UNIT DOWN TO MAINTAIN APPEARANCE. |

| CHECK TIGHTNESS OF POWER CONNECTIONS. |

6 MONTHS OR EVERY 1000 HOURS: | TAKE FLUID SAMPLE. |

| CHECK AND CLEAN INTERSTAGE MOISTURE TRAP AND DRAIN |

| MECHANISM. |

| CHANGE FLUID FILTER. |

| CHECK PRESSURE SWITCHES PS1, PS2, AND PS3. |

EVERY 8000 HOURS: | CHANGE FLUID AND FLUID FILTER (SOONER IF INDICATED BY FLUID |

| SAMPLE ANALYSIS). |

PERIODICALLY/YEARLY: | REPLACE PS2, PS3 AND PS4 NONADJUSTABLE PRESSURE |

| SWITCHES. |

| GO OVER UNIT AND CHECK ALL BOLTS FOR TIGHTNESS. |

| REPLACE SMOKE ELIMINATOR ELEMENT. |

| CHANGE AIR FILTER. |

| LUBRICATE MOTORS. |

| CHECK SAFETY SHUTDOWN SYSTEM (DO NOT TEST BY |

| INCREASING DISCHARGE TEMPERATURES). |

| CHECK AND REPLACE THE RUBBER HOSES GOING FROM THE AIRENDS |

| TO THE GEARCASE. |

| CHECK SOLENOID VALVE. |

| TEST PRESSURE RELIEF VALVE FOR PROPER OPERATION. |

| CONTACT AN AUTHORIZED QUINCY SERVICE TECHNICIAN. |

Quincy Compressor® - QSD™ | 79 |

|

|