Section VIII - Power$ync II™ Operation

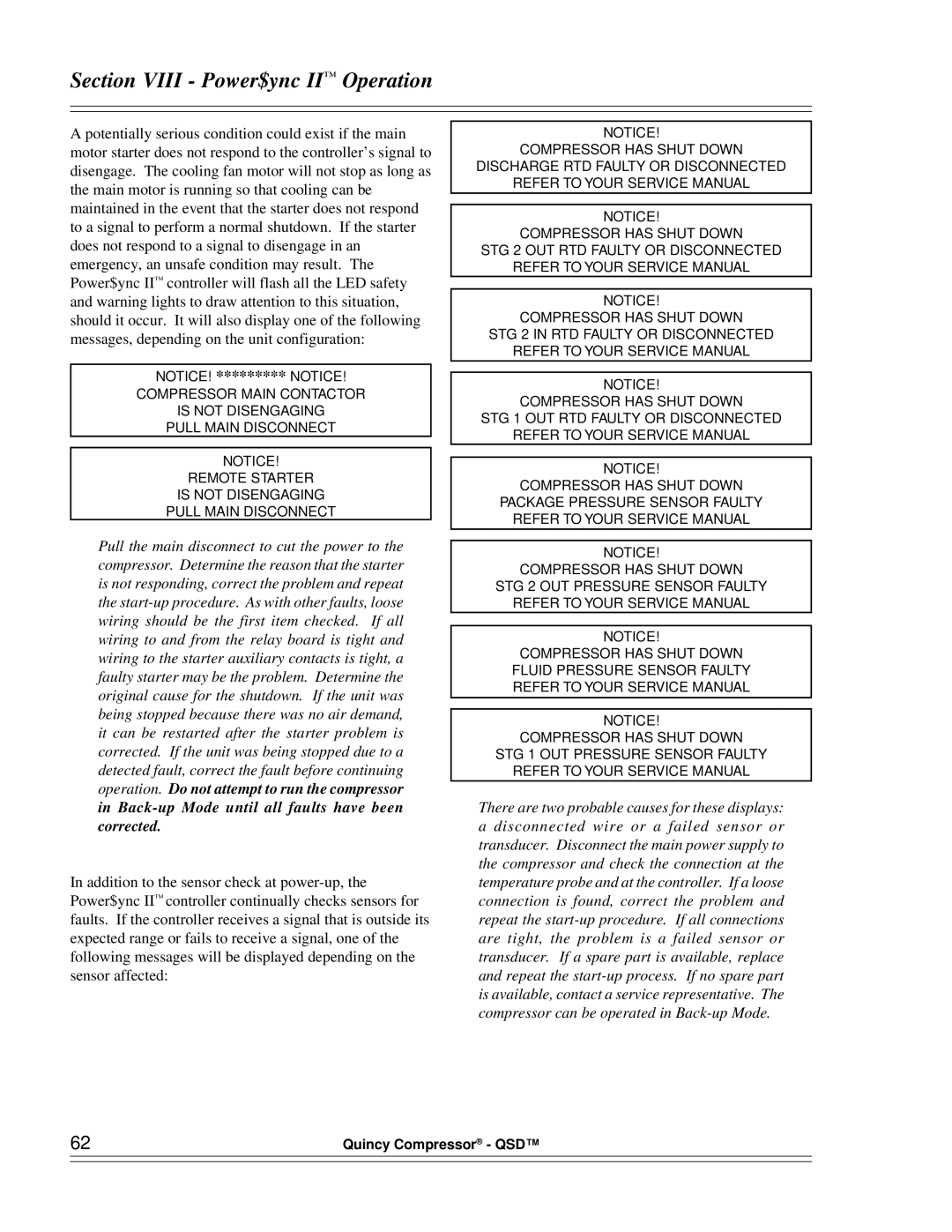

A potentially serious condition could exist if the main motor starter does not respond to the controller’s signal to disengage. The cooling fan motor will not stop as long as the main motor is running so that cooling can be maintained in the event that the starter does not respond to a signal to perform a normal shutdown. If the starter does not respond to a signal to disengage in an emergency, an unsafe condition may result. The Power$ync II™ controller will flash all the LED safety and warning lights to draw attention to this situation, should it occur. It will also display one of the following messages, depending on the unit configuration:

NOTICE! ********* NOTICE!

COMPRESSOR MAIN CONTACTOR

IS NOT DISENGAGING

PULL MAIN DISCONNECT

NOTICE!

REMOTE STARTER

IS NOT DISENGAGING

PULL MAIN DISCONNECT

Pull the main disconnect to cut the power to the compressor. Determine the reason that the starter is not responding, correct the problem and repeat the

in Back-up Mode until all faults have been corrected.

In addition to the sensor check at

Power$ync II™ controller continually checks sensors for faults. If the controller receives a signal that is outside its expected range or fails to receive a signal, one of the following messages will be displayed depending on the sensor affected:

NOTICE!

COMPRESSOR HAS SHUT DOWN

DISCHARGE RTD FAULTY OR DISCONNECTED

REFER TO YOUR SERVICE MANUAL

NOTICE!

COMPRESSOR HAS SHUT DOWN

STG 2 OUT RTD FAULTY OR DISCONNECTED

REFER TO YOUR SERVICE MANUAL

NOTICE!

COMPRESSOR HAS SHUT DOWN

STG 2 IN RTD FAULTY OR DISCONNECTED

REFER TO YOUR SERVICE MANUAL

NOTICE!

COMPRESSOR HAS SHUT DOWN

STG 1 OUT RTD FAULTY OR DISCONNECTED

REFER TO YOUR SERVICE MANUAL

NOTICE!

COMPRESSOR HAS SHUT DOWN

PACKAGE PRESSURE SENSOR FAULTY REFER TO YOUR SERVICE MANUAL

NOTICE!

COMPRESSOR HAS SHUT DOWN

STG 2 OUT PRESSURE SENSOR FAULTY

REFER TO YOUR SERVICE MANUAL

NOTICE!

COMPRESSOR HAS SHUT DOWN FLUID PRESSURE SENSOR FAULTY REFER TO YOUR SERVICE MANUAL

NOTICE!

COMPRESSOR HAS SHUT DOWN

STG 1 OUT PRESSURE SENSOR FAULTY

REFER TO YOUR SERVICE MANUAL

There are two probable causes for these displays: a disconnected wire or a failed sensor or transducer. Disconnect the main power supply to the compressor and check the connection at the temperature probe and at the controller. If a loose connection is found, correct the problem and repeat the

62 | Quincy Compressor® - QSD™ |

|

|