Section VIII - Power$ync II™ Operation

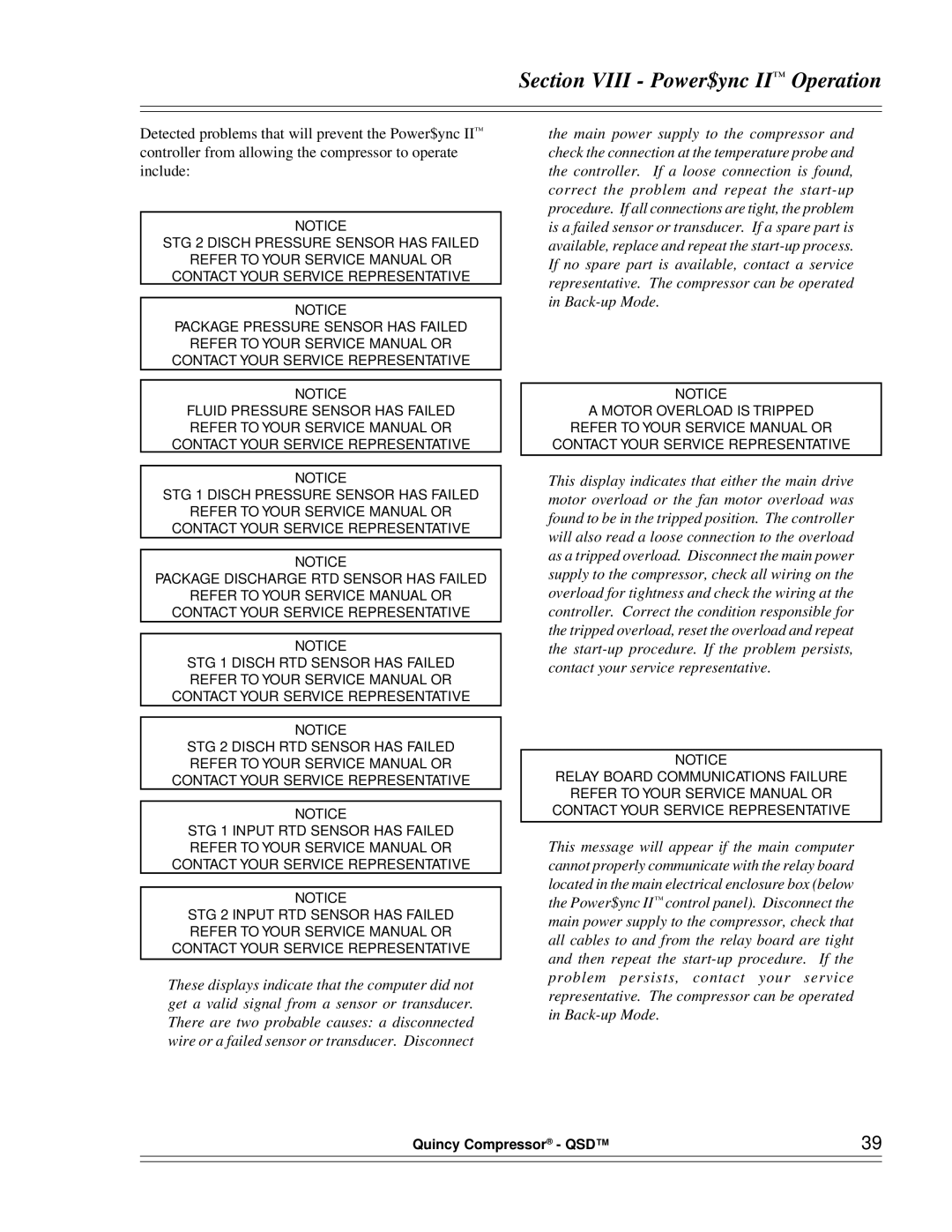

Detected problems that will prevent the Power$ync II™ controller from allowing the compressor to operate include:

NOTICE

STG 2 DISCH PRESSURE SENSOR HAS FAILED

REFER TO YOUR SERVICE MANUAL OR

CONTACT YOUR SERVICE REPRESENTATIVE

NOTICE

PACKAGE PRESSURE SENSOR HAS FAILED

REFER TO YOUR SERVICE MANUAL OR

CONTACT YOUR SERVICE REPRESENTATIVE

NOTICE

FLUID PRESSURE SENSOR HAS FAILED REFER TO YOUR SERVICE MANUAL OR CONTACT YOUR SERVICE REPRESENTATIVE

NOTICE

STG 1 DISCH PRESSURE SENSOR HAS FAILED

REFER TO YOUR SERVICE MANUAL OR

CONTACT YOUR SERVICE REPRESENTATIVE

NOTICE

PACKAGE DISCHARGE RTD SENSOR HAS FAILED

REFER TO YOUR SERVICE MANUAL OR

CONTACT YOUR SERVICE REPRESENTATIVE

NOTICE

STG 1 DISCH RTD SENSOR HAS FAILED REFER TO YOUR SERVICE MANUAL OR CONTACT YOUR SERVICE REPRESENTATIVE

NOTICE

STG 2 DISCH RTD SENSOR HAS FAILED REFER TO YOUR SERVICE MANUAL OR CONTACT YOUR SERVICE REPRESENTATIVE

NOTICE

STG 1 INPUT RTD SENSOR HAS FAILED REFER TO YOUR SERVICE MANUAL OR CONTACT YOUR SERVICE REPRESENTATIVE

NOTICE

STG 2 INPUT RTD SENSOR HAS FAILED REFER TO YOUR SERVICE MANUAL OR CONTACT YOUR SERVICE REPRESENTATIVE

These displays indicate that the computer did not get a valid signal from a sensor or transducer. There are two probable causes: a disconnected wire or a failed sensor or transducer. Disconnect

the main power supply to the compressor and check the connection at the temperature probe and the controller. If a loose connection is found, correct the problem and repeat the

NOTICE

A MOTOR OVERLOAD IS TRIPPED

REFER TO YOUR SERVICE MANUAL OR

CONTACT YOUR SERVICE REPRESENTATIVE

This display indicates that either the main drive motor overload or the fan motor overload was found to be in the tripped position. The controller will also read a loose connection to the overload as a tripped overload. Disconnect the main power supply to the compressor, check all wiring on the overload for tightness and check the wiring at the controller. Correct the condition responsible for the tripped overload, reset the overload and repeat the

NOTICE

RELAY BOARD COMMUNICATIONS FAILURE

REFER TO YOUR SERVICE MANUAL OR

CONTACT YOUR SERVICE REPRESENTATIVE

This message will appear if the main computer cannot properly communicate with the relay board located in the main electrical enclosure box (below the Power$ync II™ control panel). Disconnect the main power supply to the compressor, check that all cables to and from the relay board are tight and then repeat the

Quincy Compressor® - QSD™ | 39 |

|

|