Section VIII - Power$ync II™ Operation

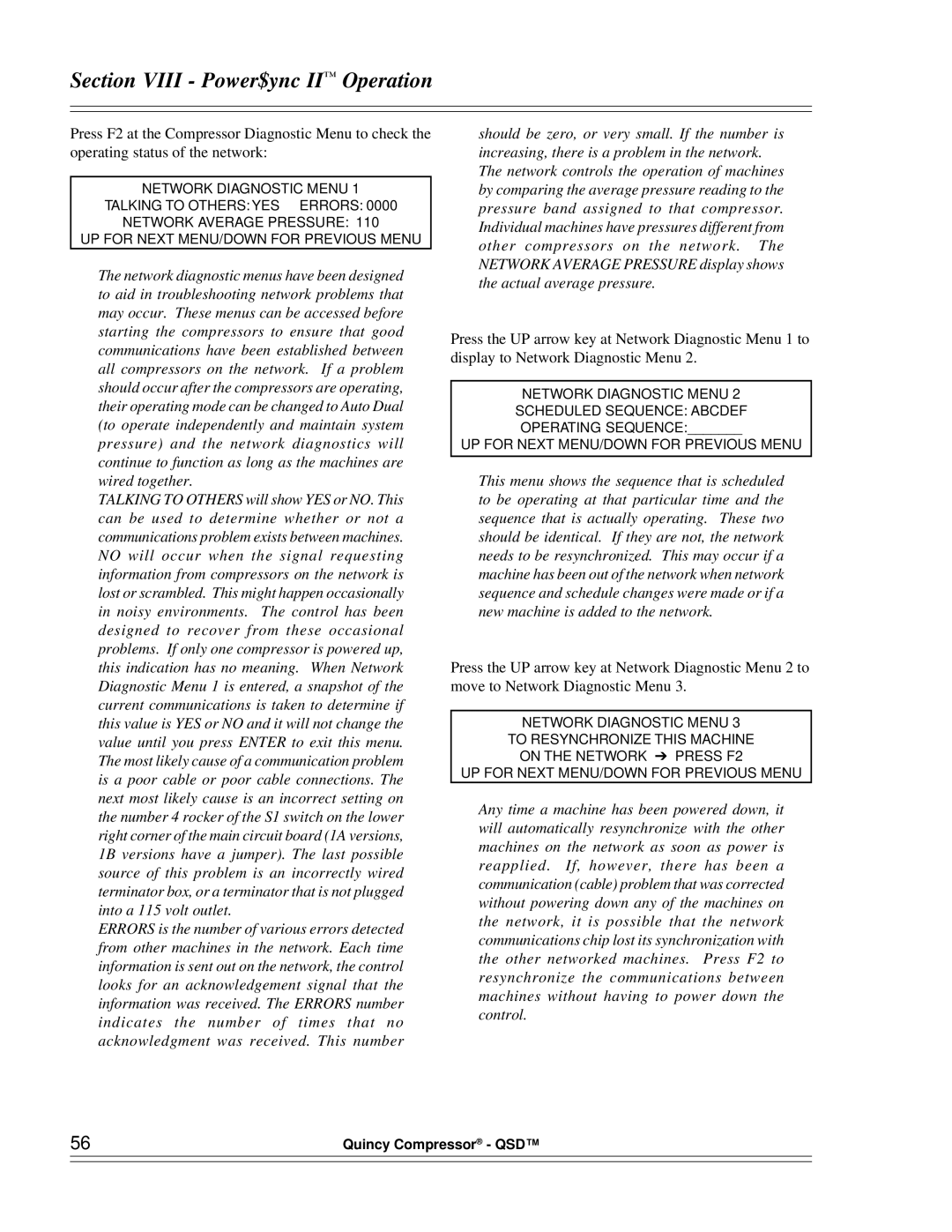

Press F2 at the Compressor Diagnostic Menu to check the operating status of the network:

NETWORK DIAGNOSTIC MENU 1

TALKING TO OTHERS: YES ERRORS: 0000

NETWORK AVERAGE PRESSURE: 110

UP FOR NEXT MENU/DOWN FOR PREVIOUS MENU

The network diagnostic menus have been designed to aid in troubleshooting network problems that may occur. These menus can be accessed before starting the compressors to ensure that good communications have been established between all compressors on the network. If a problem should occur after the compressors are operating, their operating mode can be changed to Auto Dual (to operate independently and maintain system pressure) and the network diagnostics will continue to function as long as the machines are wired together.

TALKING TO OTHERS will show YES or NO. This can be used to determine whether or not a communications problem exists between machines. NO will occur when the signal requesting information from compressors on the network is lost or scrambled. This might happen occasionally in noisy environments. The control has been designed to recover from these occasional problems. If only one compressor is powered up, this indication has no meaning. When Network Diagnostic Menu 1 is entered, a snapshot of the current communications is taken to determine if this value is YES or NO and it will not change the value until you press ENTER to exit this menu. The most likely cause of a communication problem is a poor cable or poor cable connections. The next most likely cause is an incorrect setting on the number 4 rocker of the S1 switch on the lower right corner of the main circuit board (1A versions, 1B versions have a jumper). The last possible source of this problem is an incorrectly wired terminator box, or a terminator that is not plugged into a 115 volt outlet.

ERRORS is the number of various errors detected from other machines in the network. Each time information is sent out on the network, the control looks for an acknowledgement signal that the information was received. The ERRORS number indicates the number of times that no acknowledgment was received. This number

should be zero, or very small. If the number is increasing, there is a problem in the network. The network controls the operation of machines by comparing the average pressure reading to the pressure band assigned to that compressor. Individual machines have pressures different from other compressors on the network. The NETWORK AVERAGE PRESSURE display shows the actual average pressure.

Press the UP arrow key at Network Diagnostic Menu 1 to display to Network Diagnostic Menu 2.

NETWORK DIAGNOSTIC MENU 2

SCHEDULED SEQUENCE: ABCDEF

OPERATING SEQUENCE:_______

UP FOR NEXT MENU/DOWN FOR PREVIOUS MENU

This menu shows the sequence that is scheduled to be operating at that particular time and the sequence that is actually operating. These two should be identical. If they are not, the network needs to be resynchronized. This may occur if a machine has been out of the network when network sequence and schedule changes were made or if a new machine is added to the network.

Press the UP arrow key at Network Diagnostic Menu 2 to move to Network Diagnostic Menu 3.

NETWORK DIAGNOSTIC MENU 3

TO RESYNCHRONIZE THIS MACHINE

ON THE NETWORK ➔ PRESS F2

UP FOR NEXT MENU/DOWN FOR PREVIOUS MENU

Any time a machine has been powered down, it will automatically resynchronize with the other machines on the network as soon as power is reapplied. If, however, there has been a communication (cable) problem that was corrected without powering down any of the machines on the network, it is possible that the network communications chip lost its synchronization with the other networked machines. Press F2 to resynchronize the communications between machines without having to power down the control.

56 | Quincy Compressor® - QSD™ |

|

|